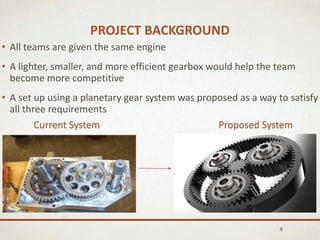

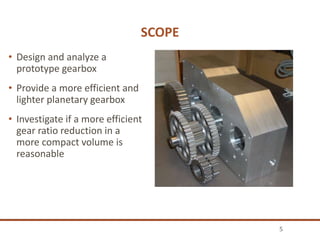

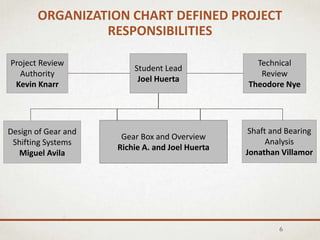

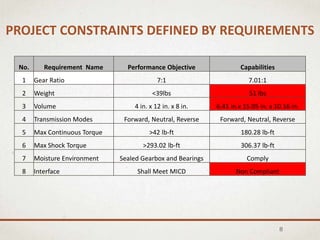

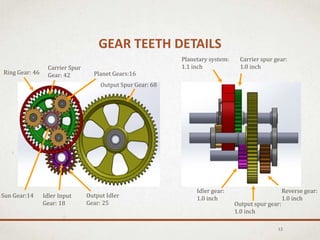

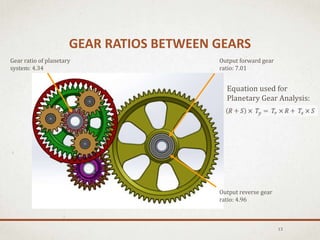

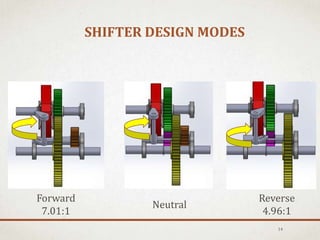

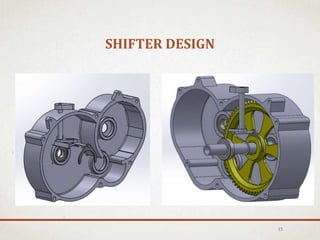

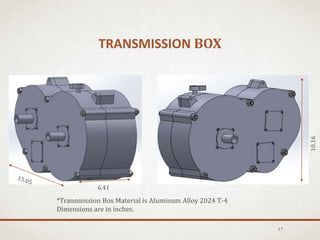

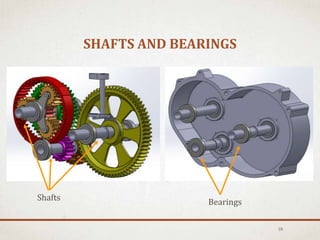

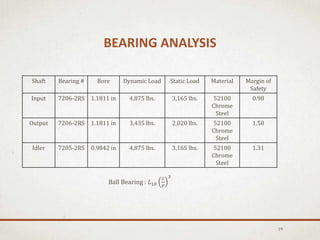

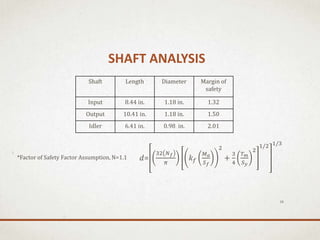

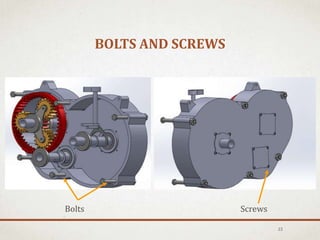

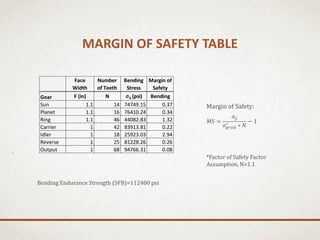

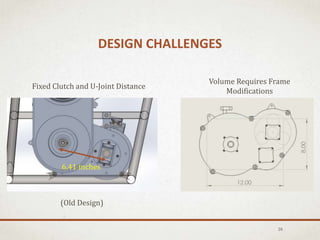

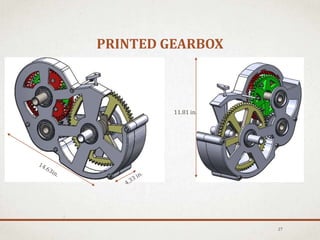

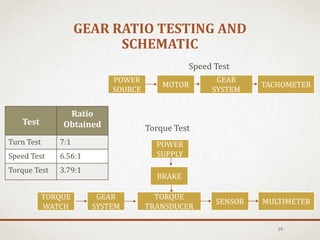

The document summarizes the design of a planetary gear transmission for a Baja SAE vehicle. It outlines the project background, constraints, and design process. The transmission uses a planetary gear system to achieve forward, neutral, and reverse with a 7:1 gear ratio in a compact design. Team members presented on the gear and shifting systems, transmission box, shafts, bearings, and safety analysis. Testing showed gear ratios of 6.56:1 for speed and 3.79:1 for torque. The basic functioning design demonstrates the feasibility of a lighter, more efficient planetary transmission for the competition.