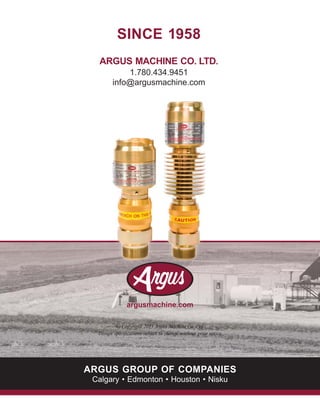

This document provides product information for Argus Pressure Switches, Isolation Valves, and related pressure control products. It summarizes the products' specifications, certifications, materials, dimensions, and applications. The products conform to various industry standards and are designed for reliable and safe pressure monitoring and control in oil and gas well sites and other industrial processes.