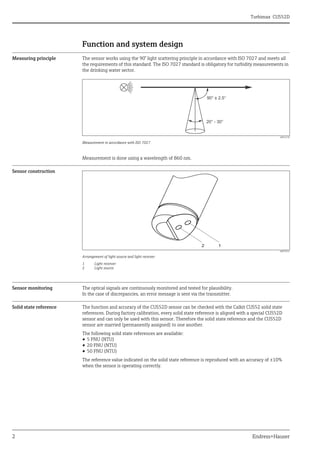

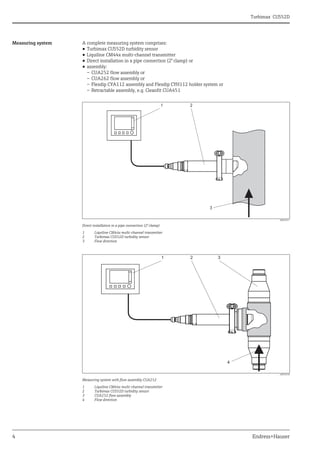

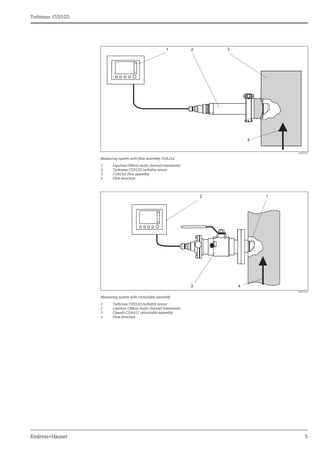

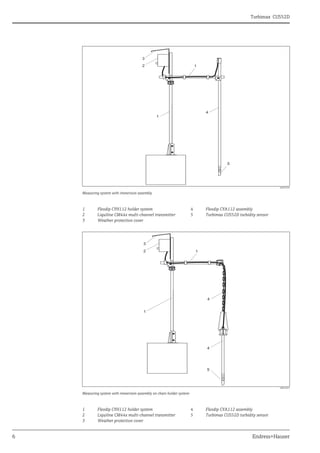

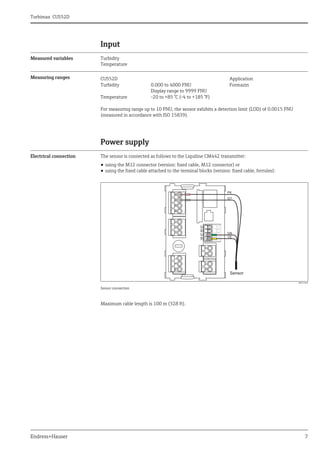

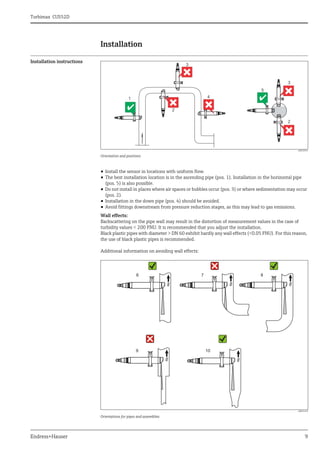

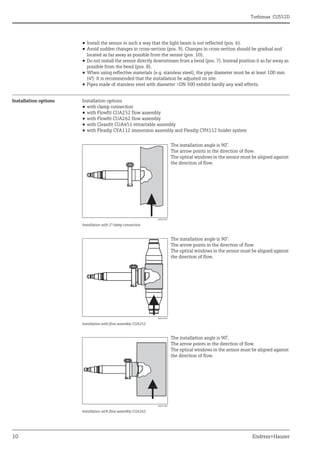

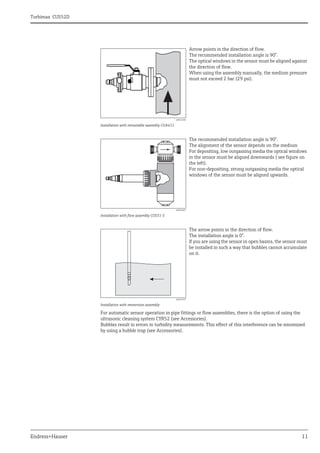

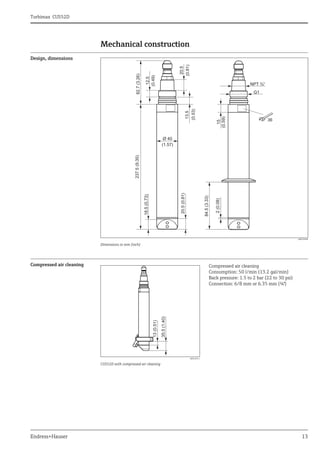

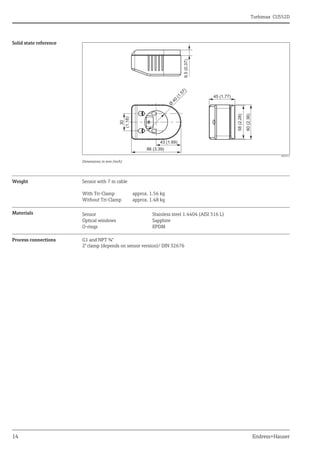

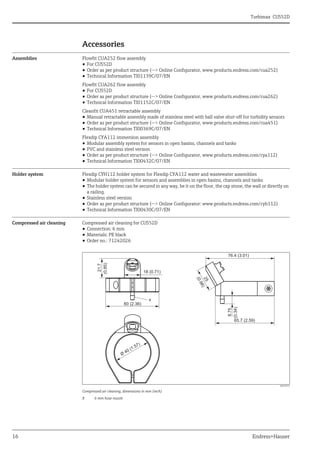

The document provides technical information on the turbimax cus52d turbidity sensor, designed for low to medium turbidity applications in drinking and process water. It includes details on installation, operating principles, calibration, and measuring systems, emphasizing compliance with ISO 7027 standards. The sensor features hygienic design for direct pipe mounting, standardized communication for easy integration, and advanced monitoring capabilities.