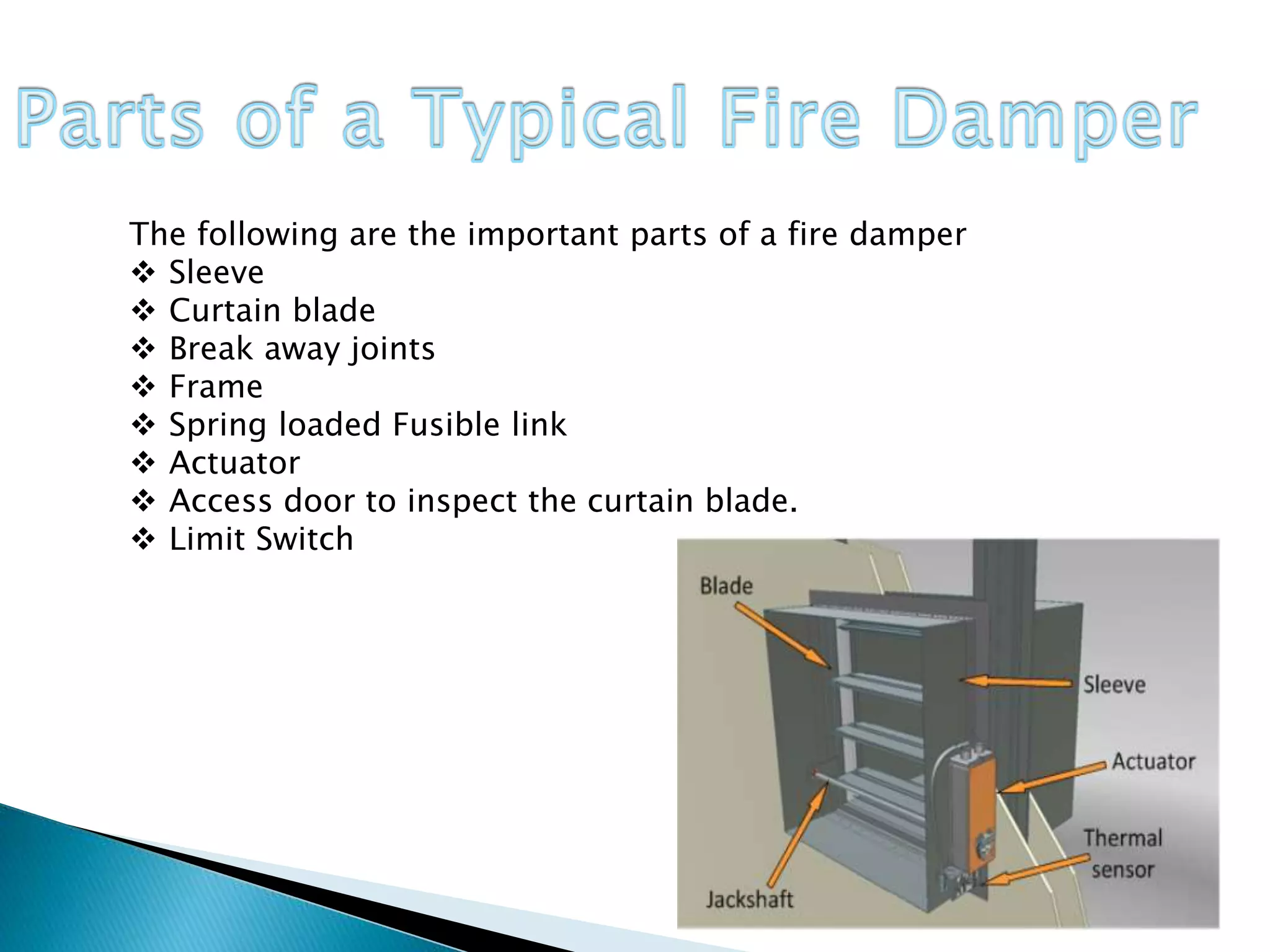

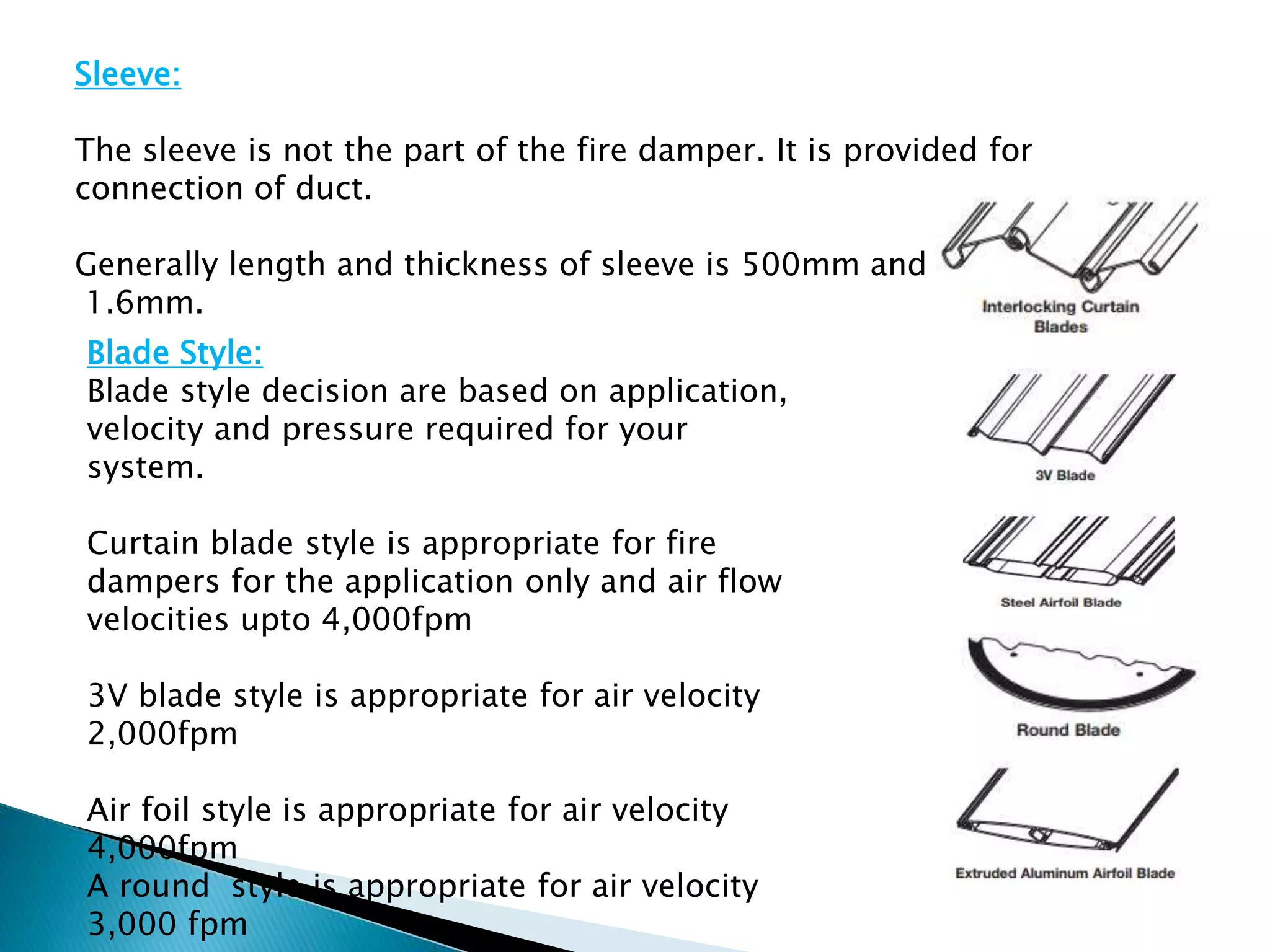

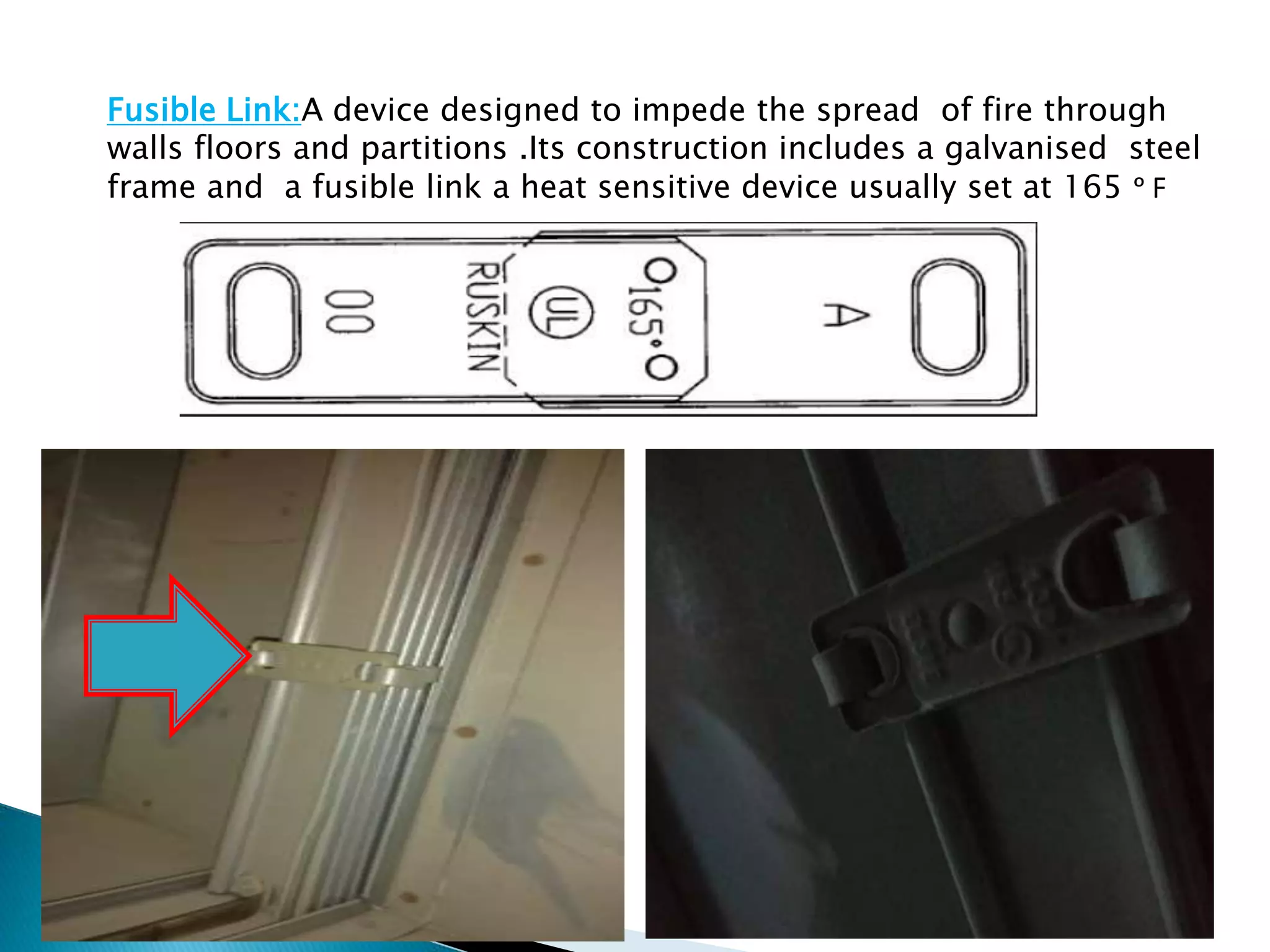

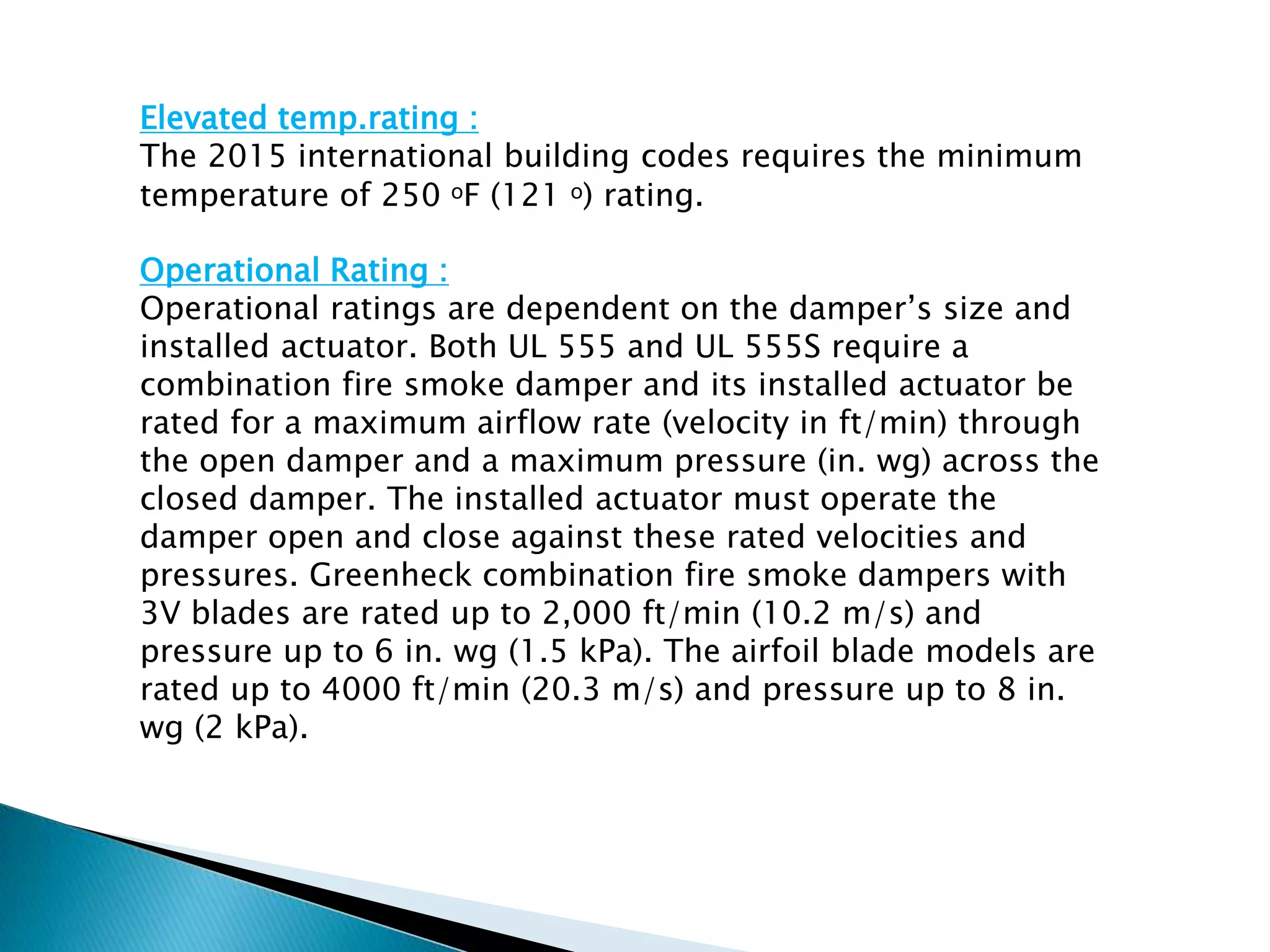

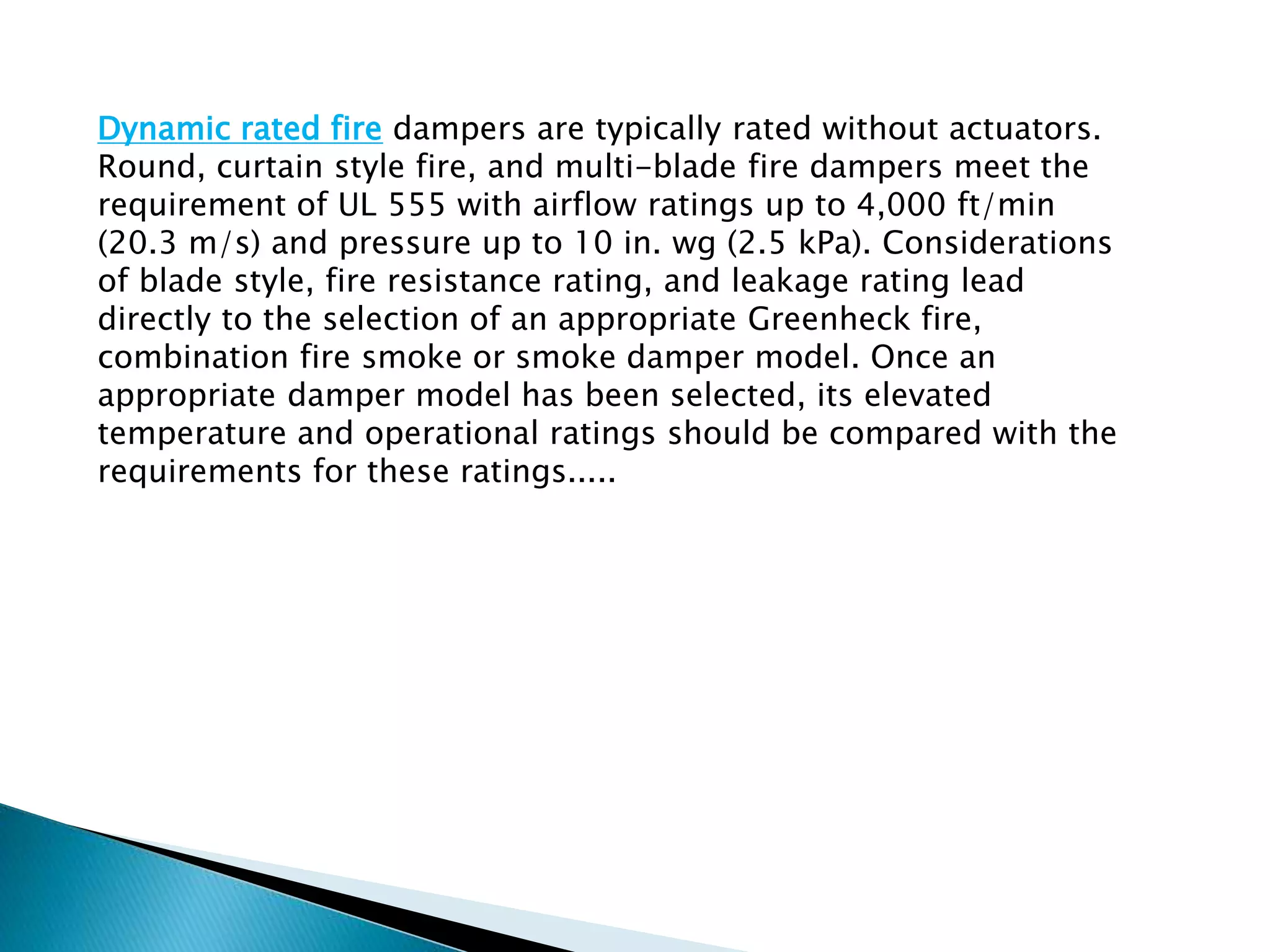

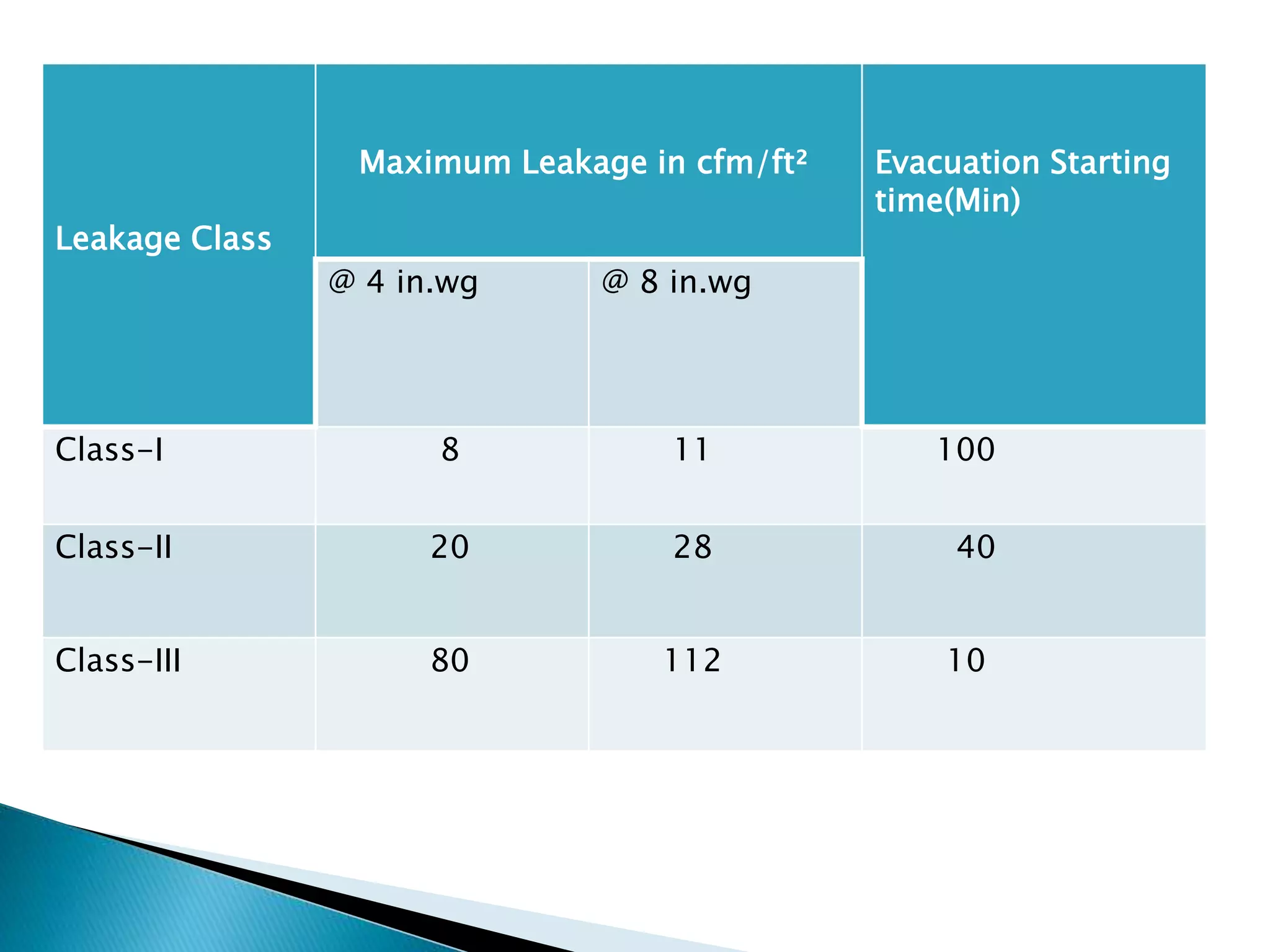

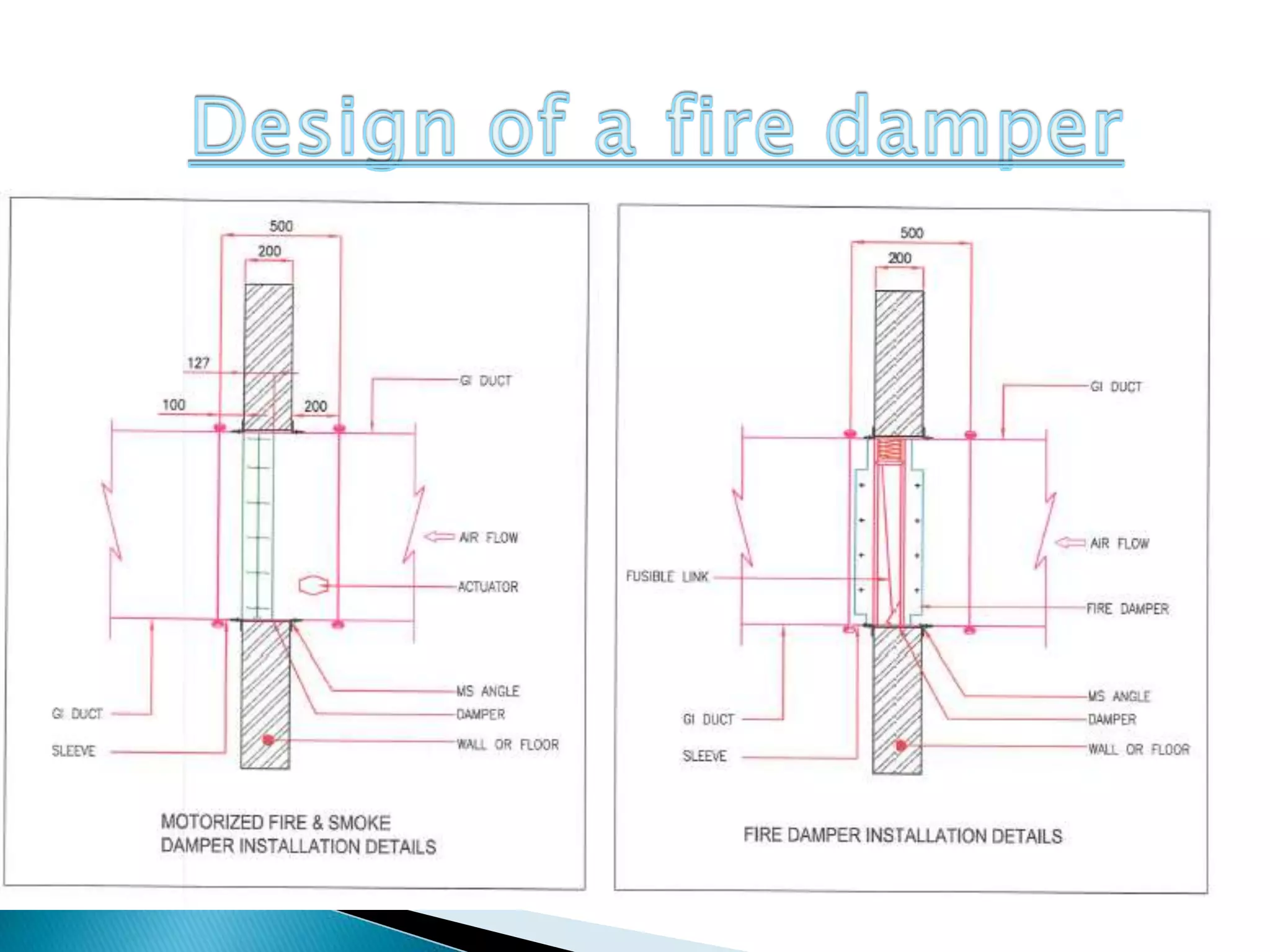

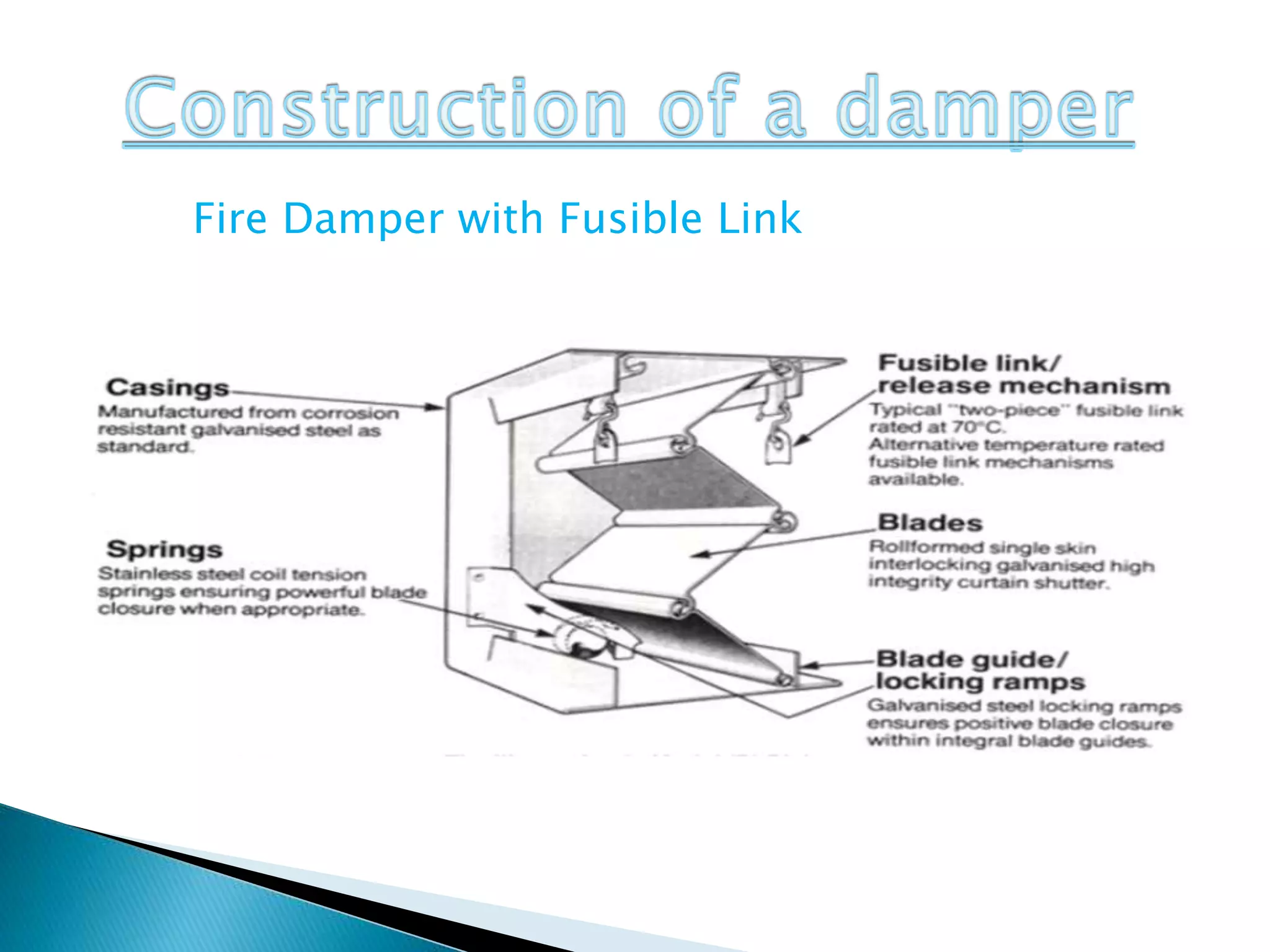

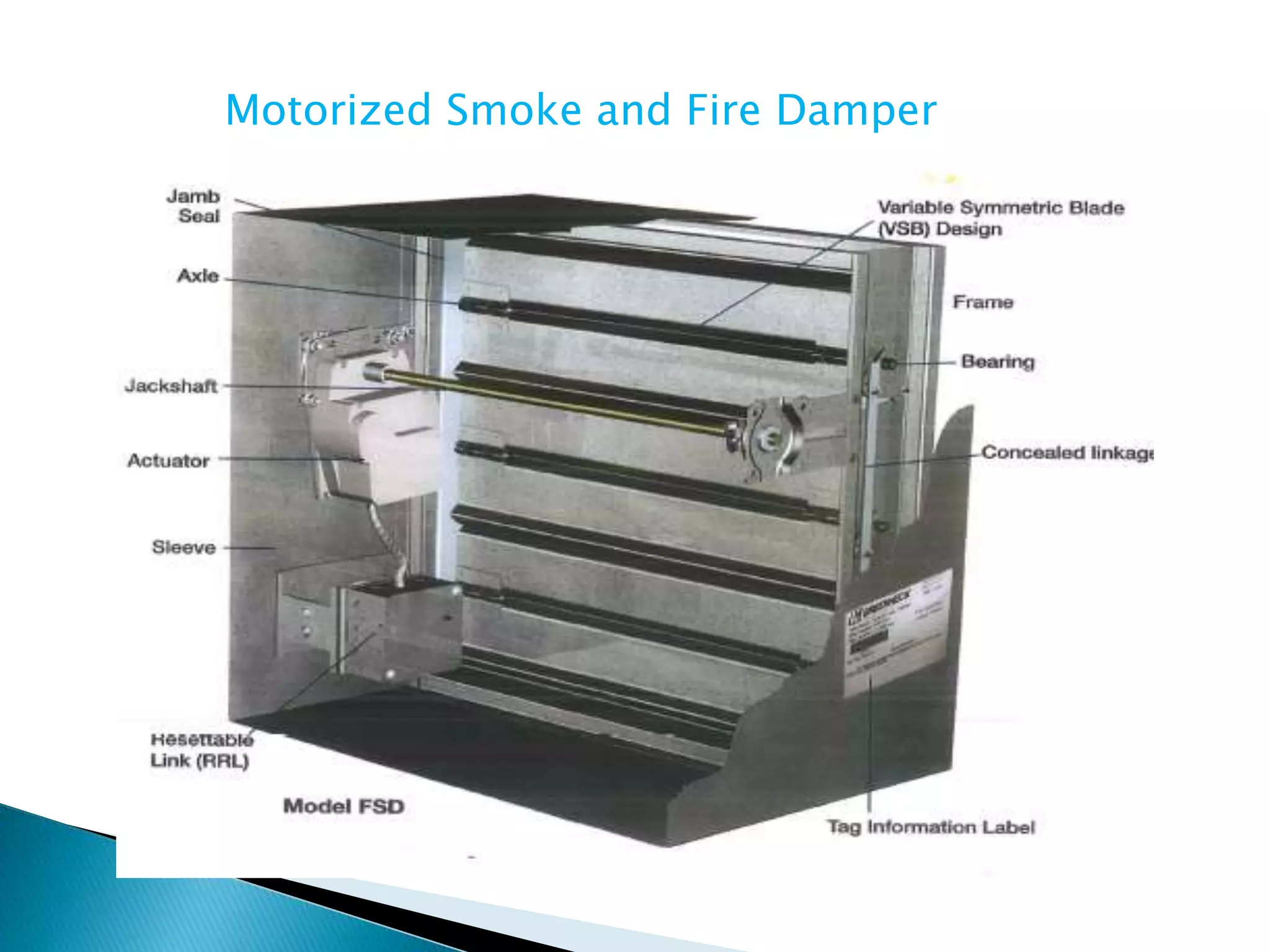

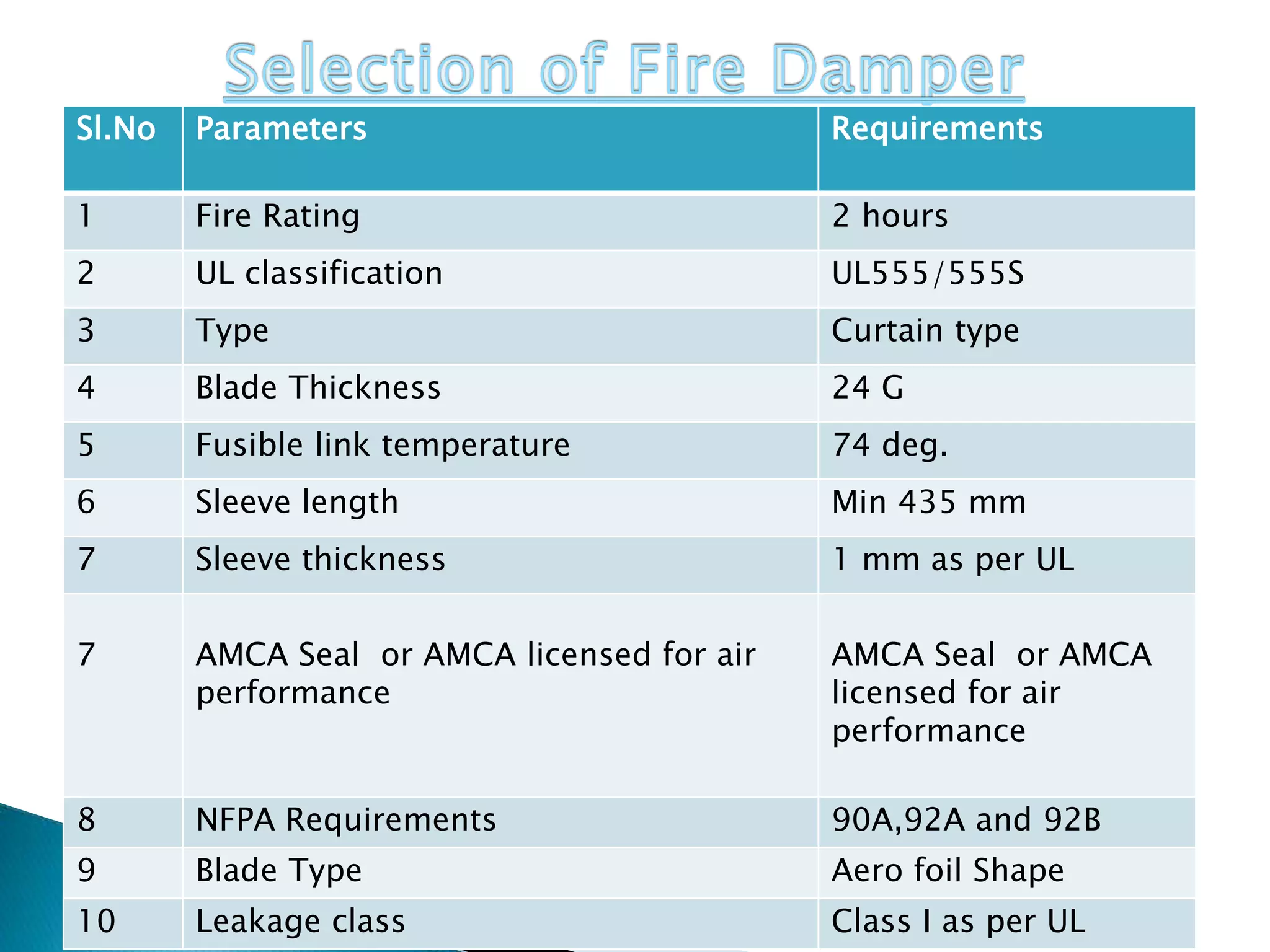

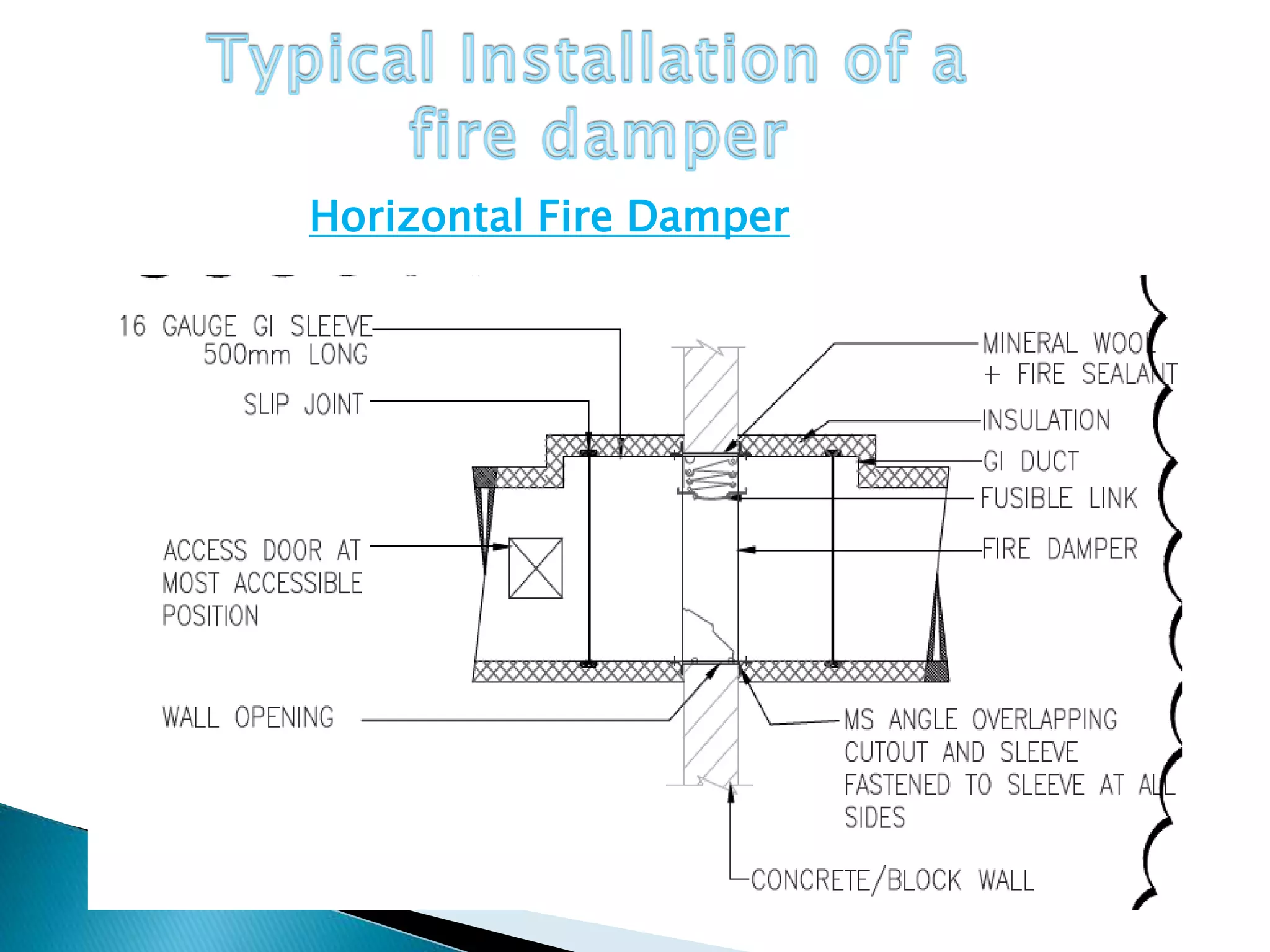

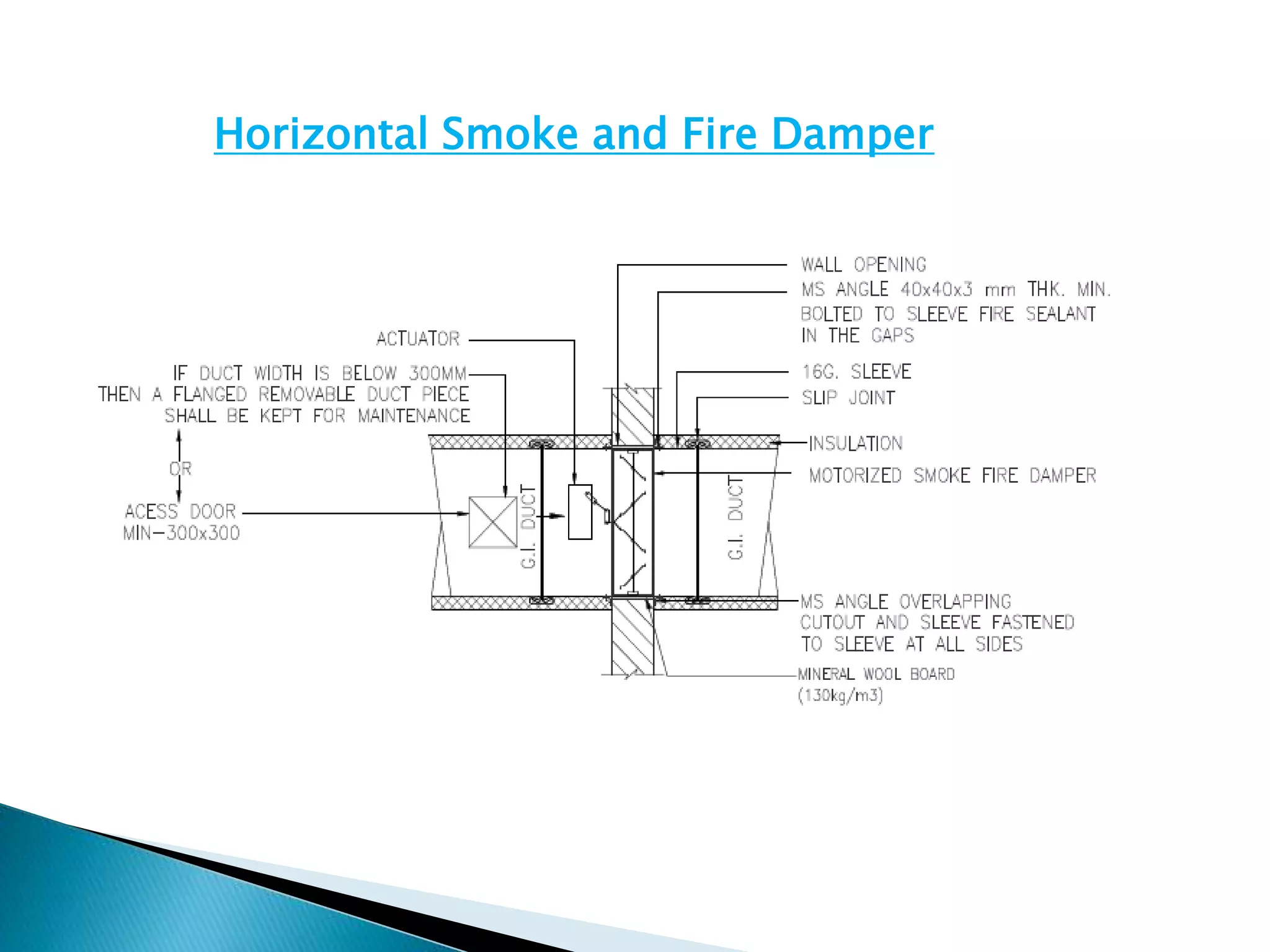

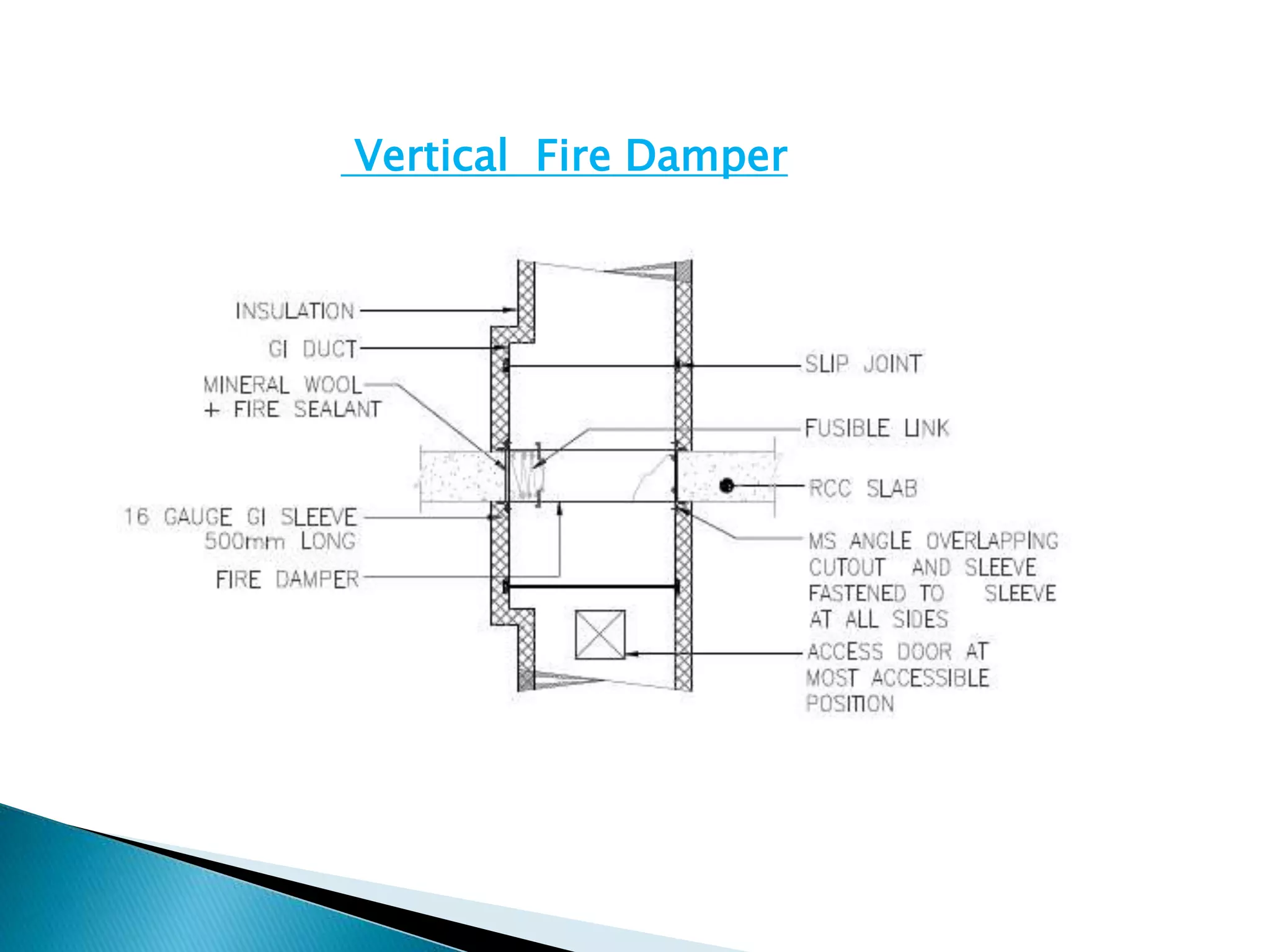

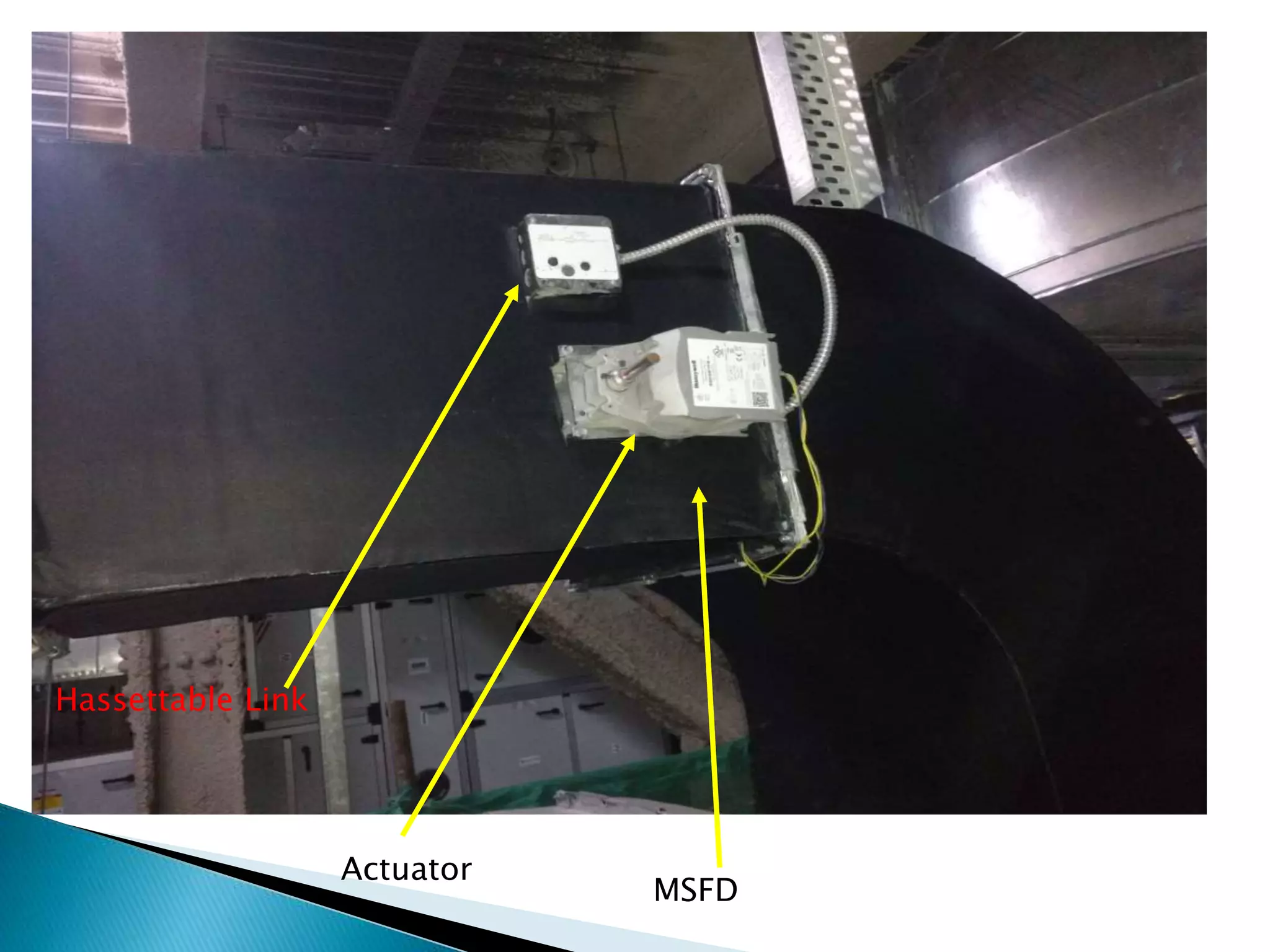

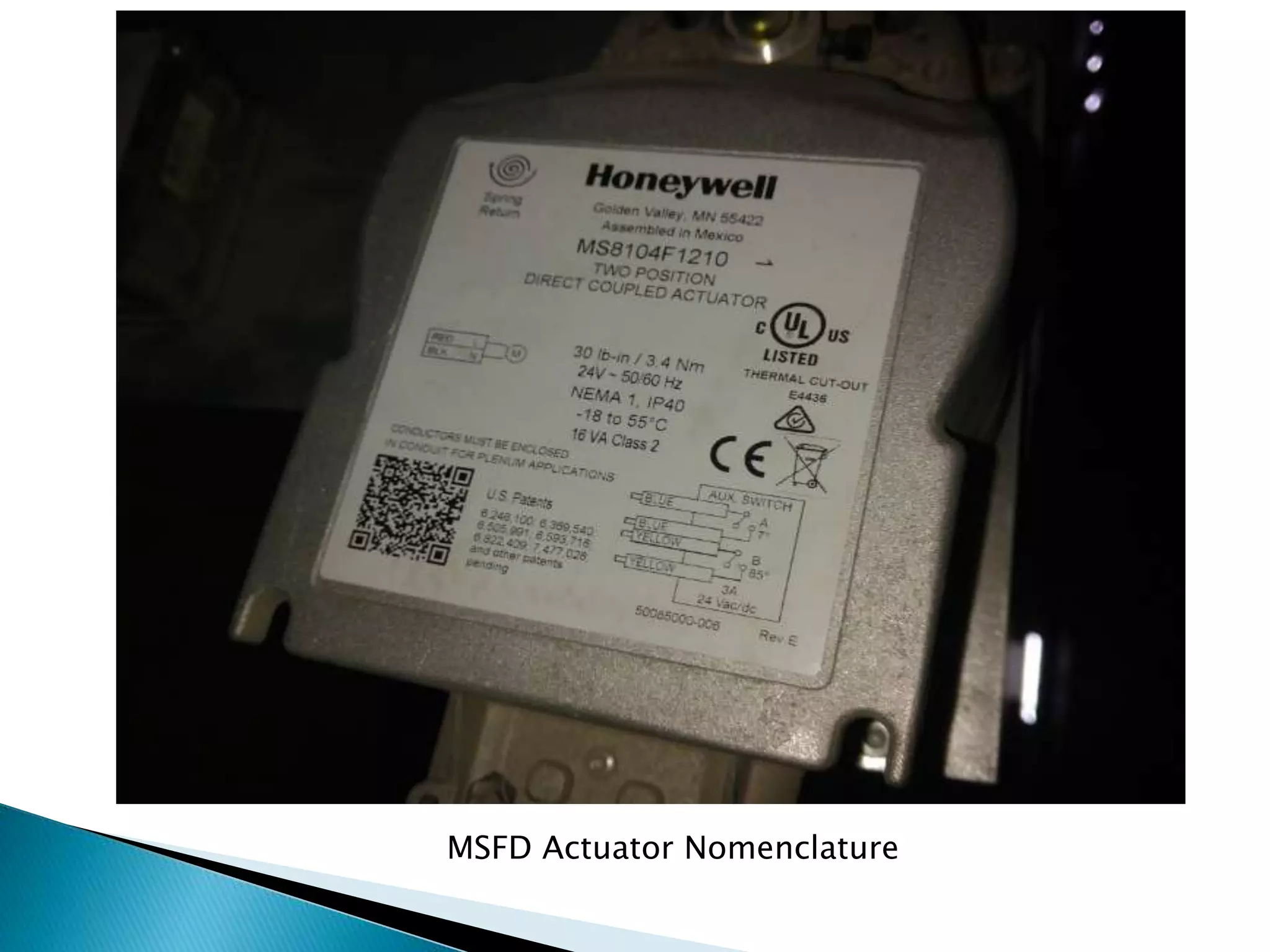

Fire dampers and smoke dampers are passive devices used in HVAC systems to prevent the spread of fire and smoke through ductwork. Fire dampers are classified as static or dynamic depending on if the HVAC fan can run during a fire. Smoke dampers prevent smoke passage. Key components include sleeves, curtain blades, frames, and fusible links that cause the damper to close when temperatures reach 165°F. Dampers are rated by fire resistance, elevated temperature resistance, operational airflow/pressure limits, and leakage class.