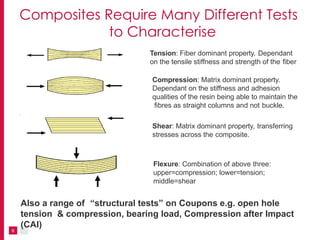

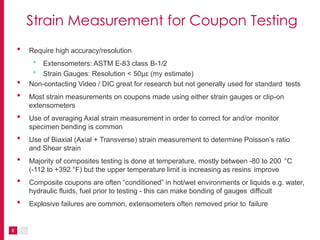

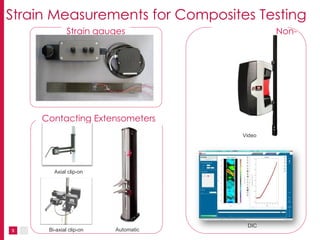

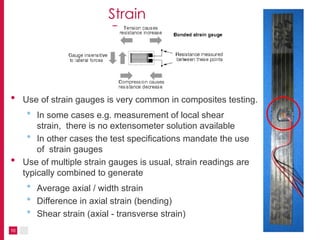

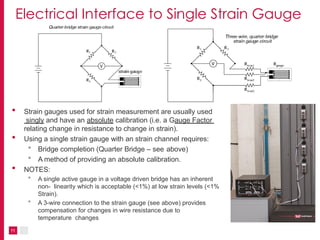

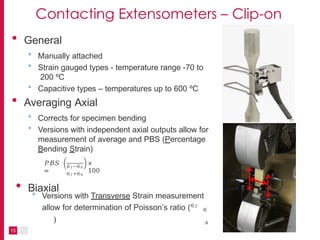

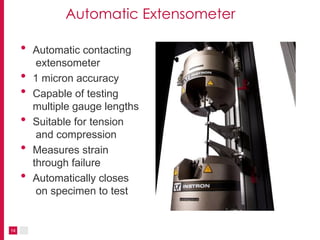

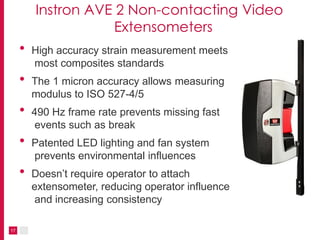

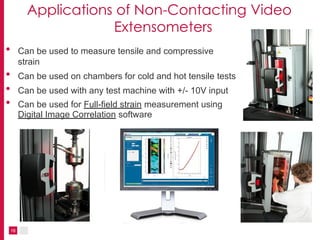

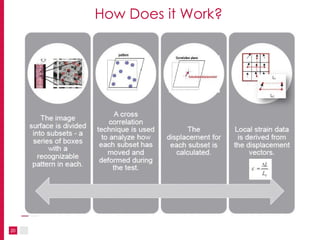

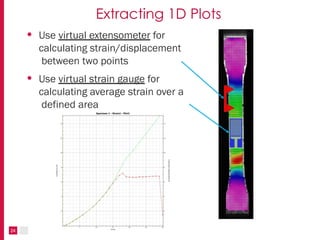

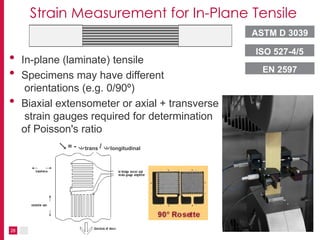

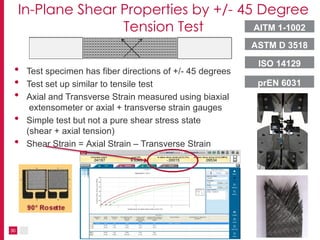

Traditional methods for strain measurement are extensometers and strain gauges, both of which require physical contact between instrumentation and specimen, and are directional. Extensometers generally record a strain over a significant length of material, typically up to 25 mm, or greater.