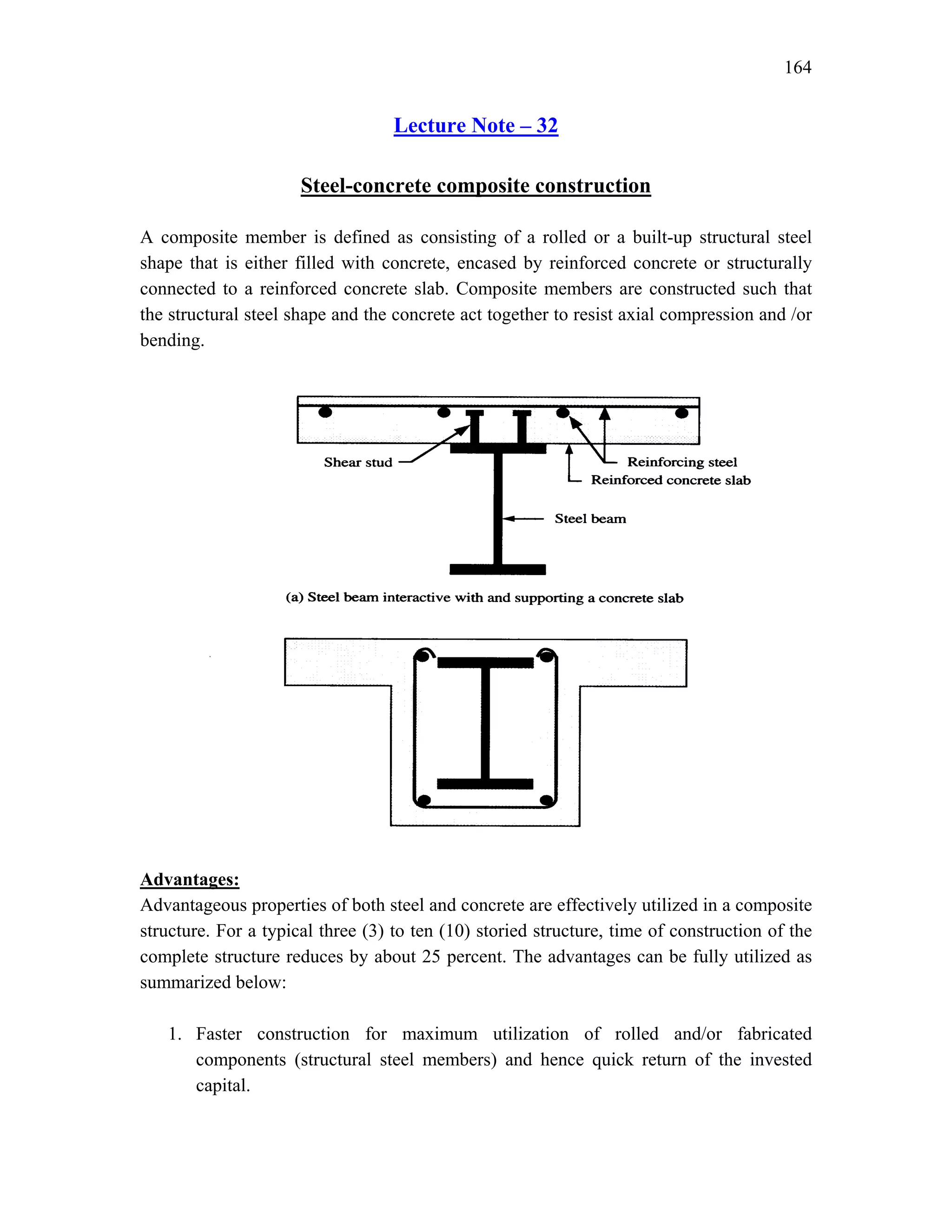

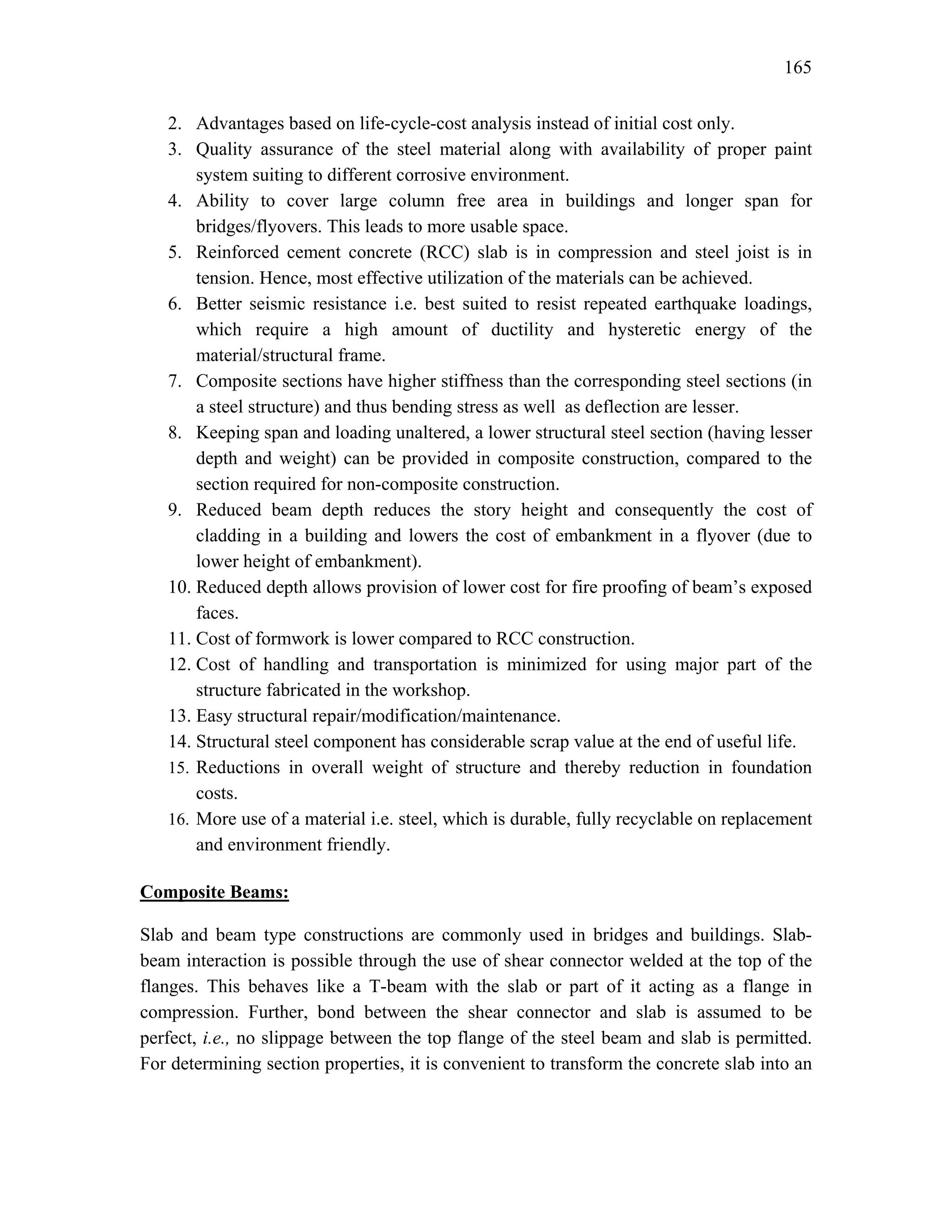

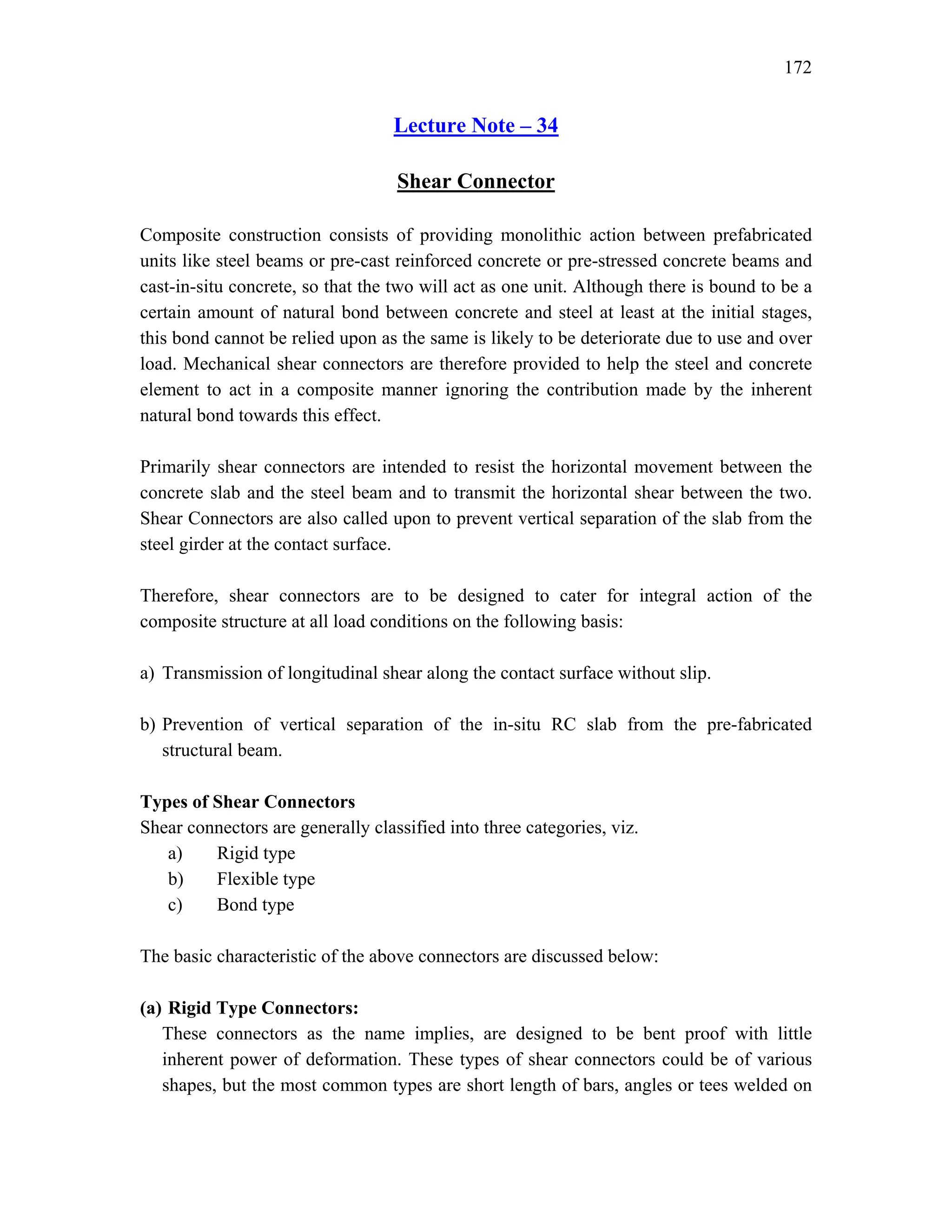

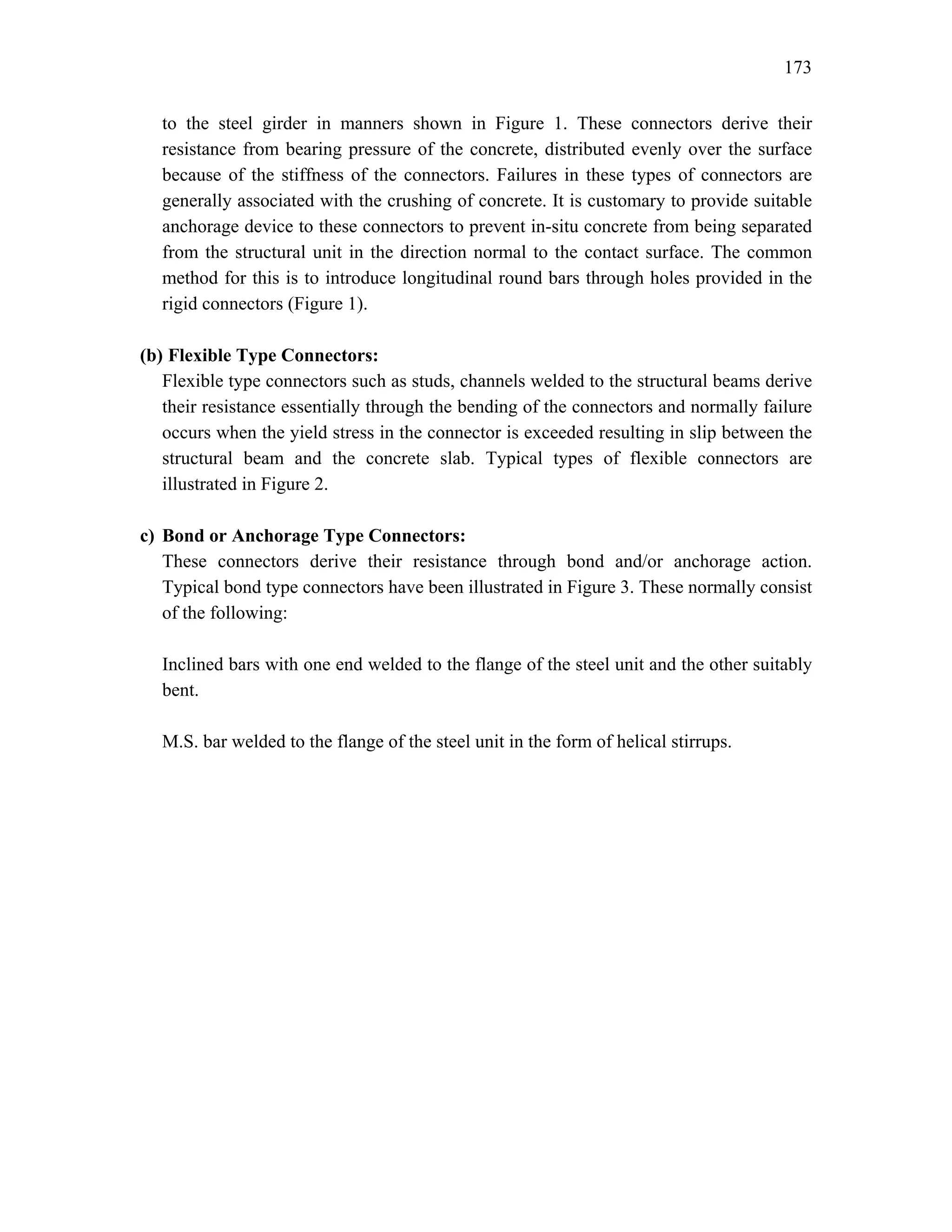

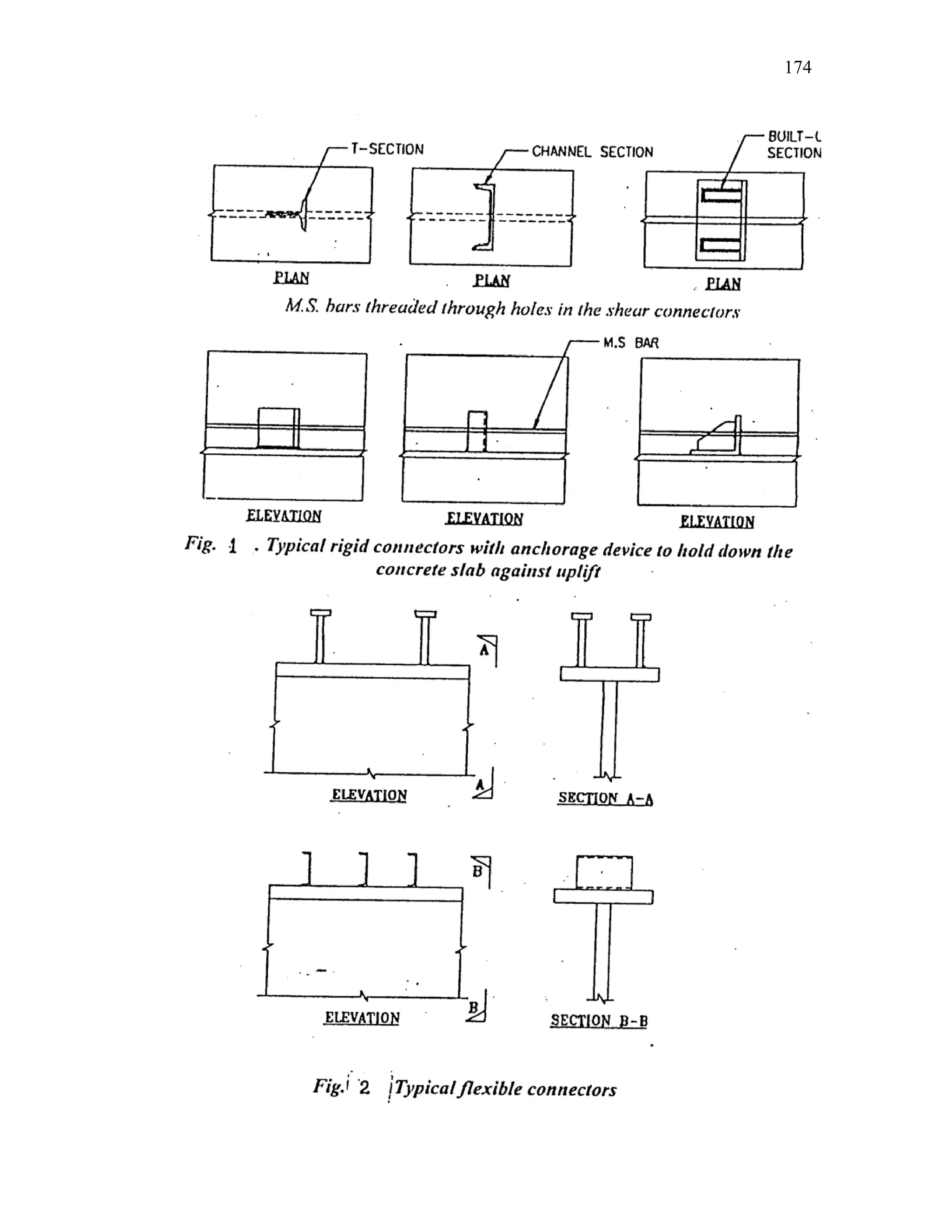

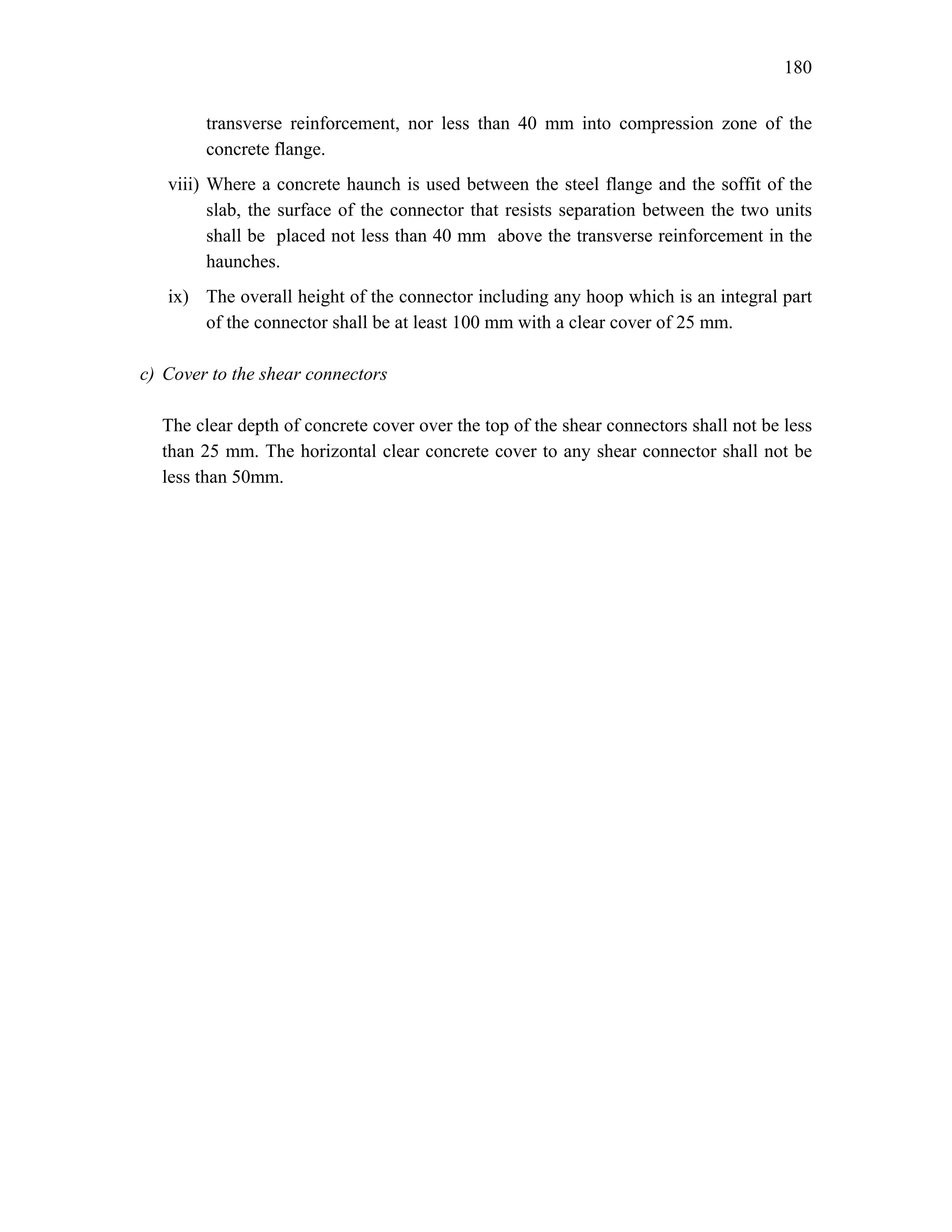

This document discusses steel-concrete composite construction. It describes shear connectors, which provide composite action between steel beams and concrete slabs. There are three main types of shear connectors: rigid connectors made of steel bars or angles that resist shear through bearing pressure; flexible stud connectors that bend and fail through yielding; and bond-type connectors that rely on bond and anchoring. The document discusses the design of shear connectors according to Indian codes IRC 22-1986 and IS 11384-1985, providing methods to calculate the design strength of shear connectors.

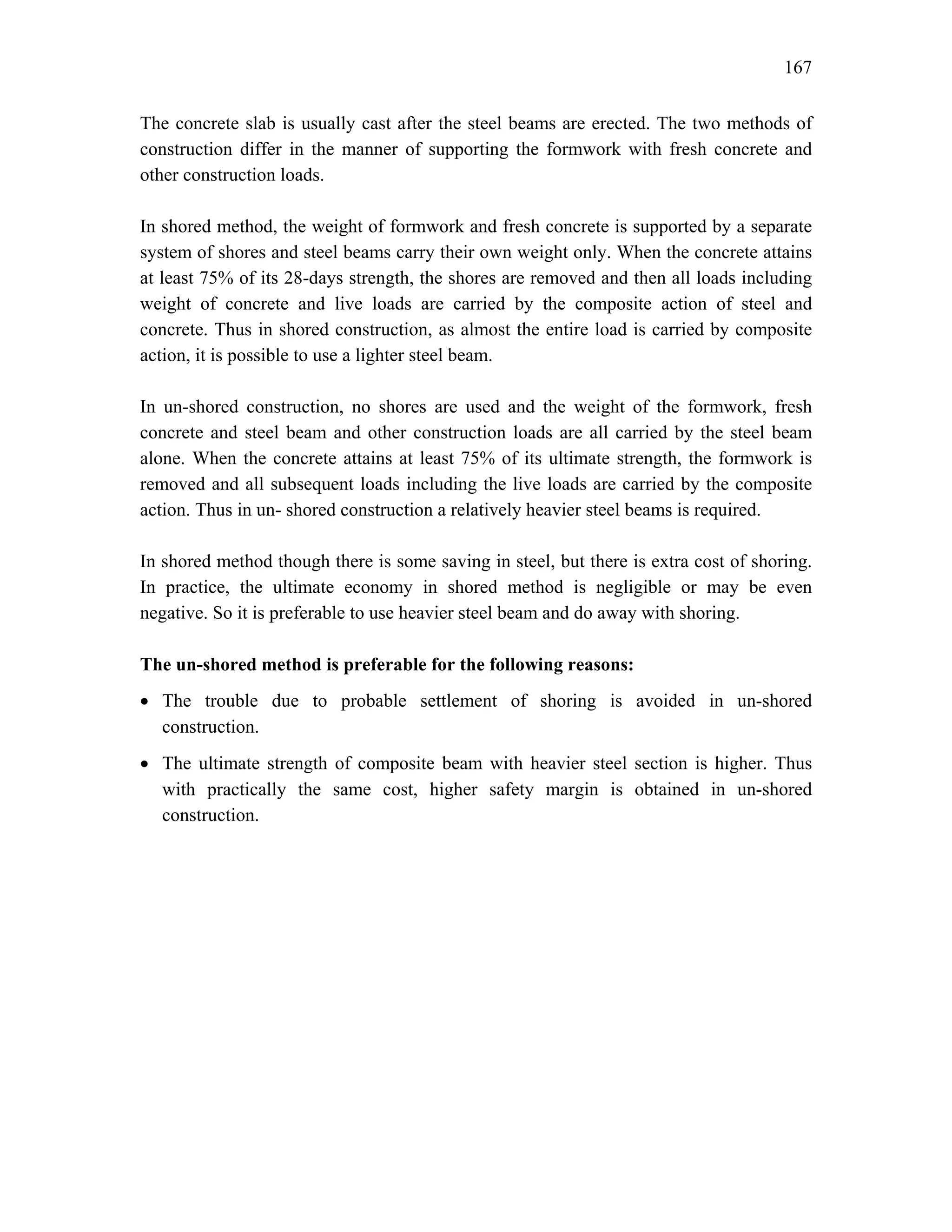

![197

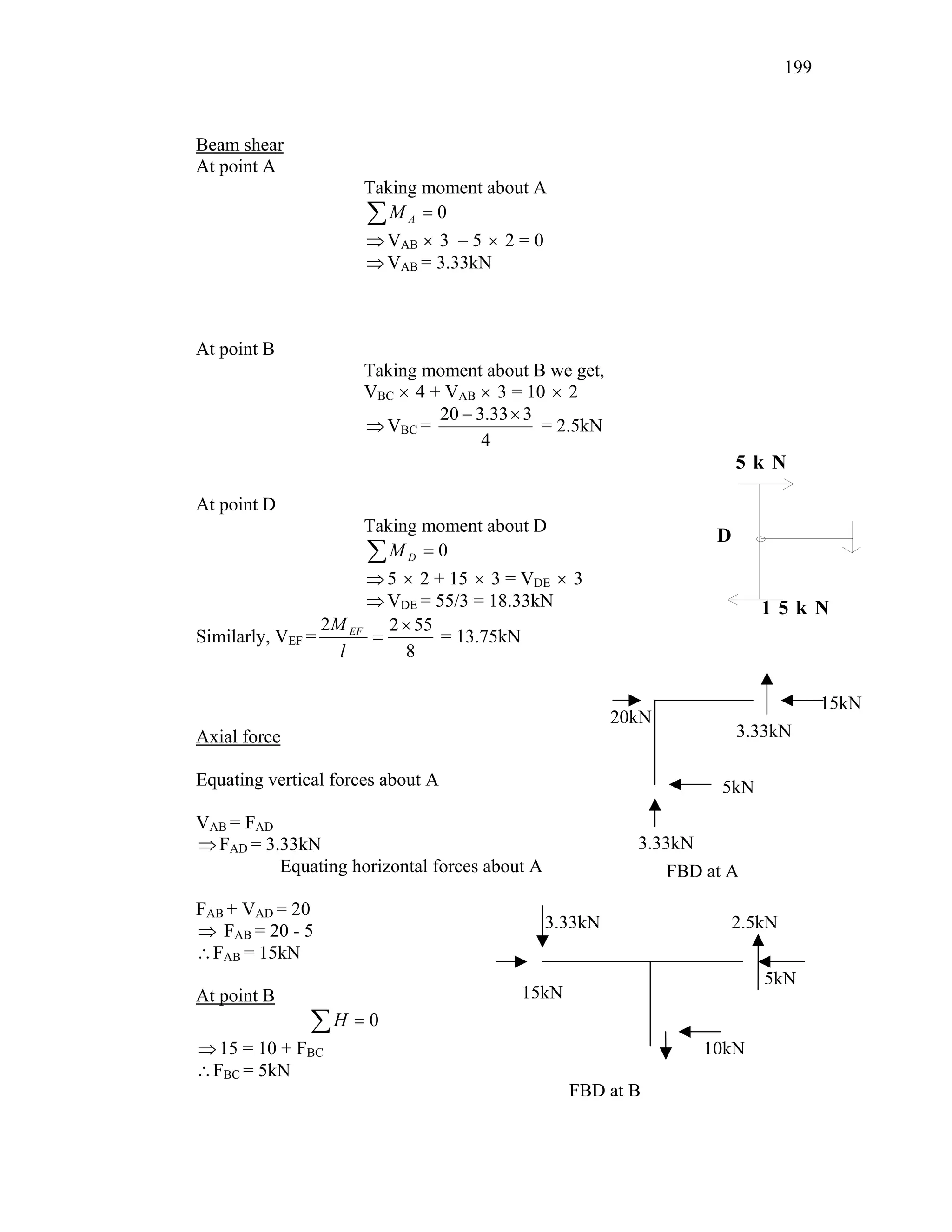

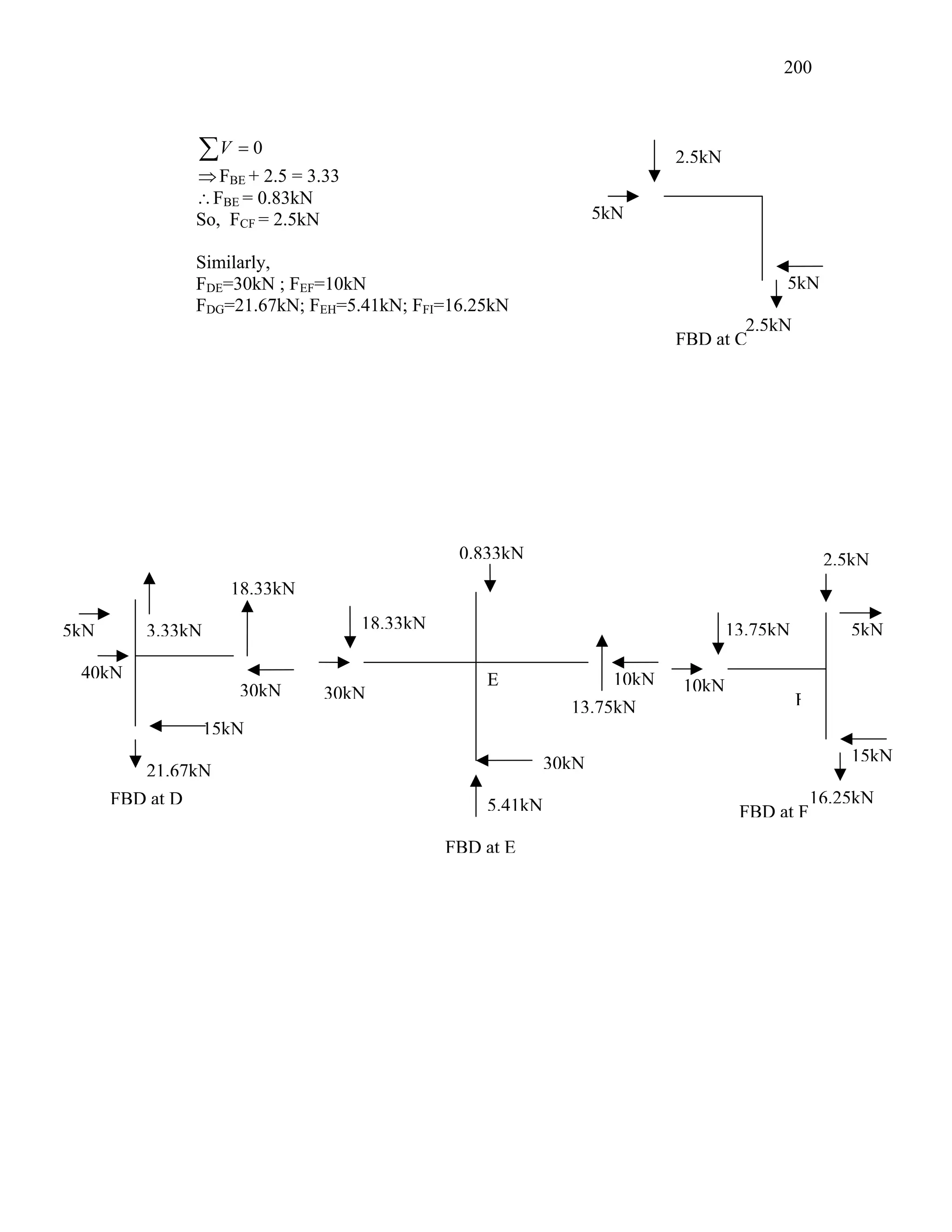

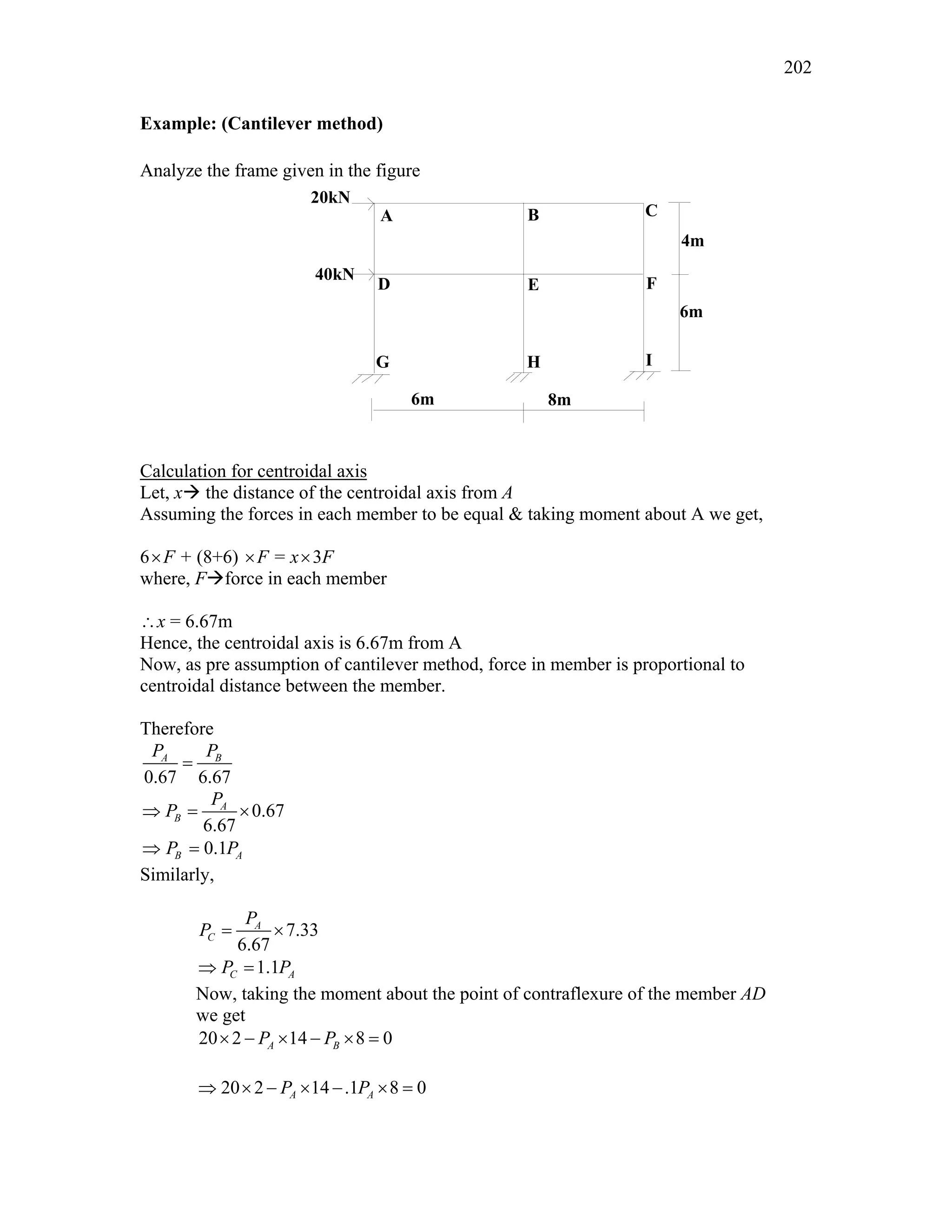

A B C

D E F

G H I

4m

6m

6m 8m

20kN

40kN

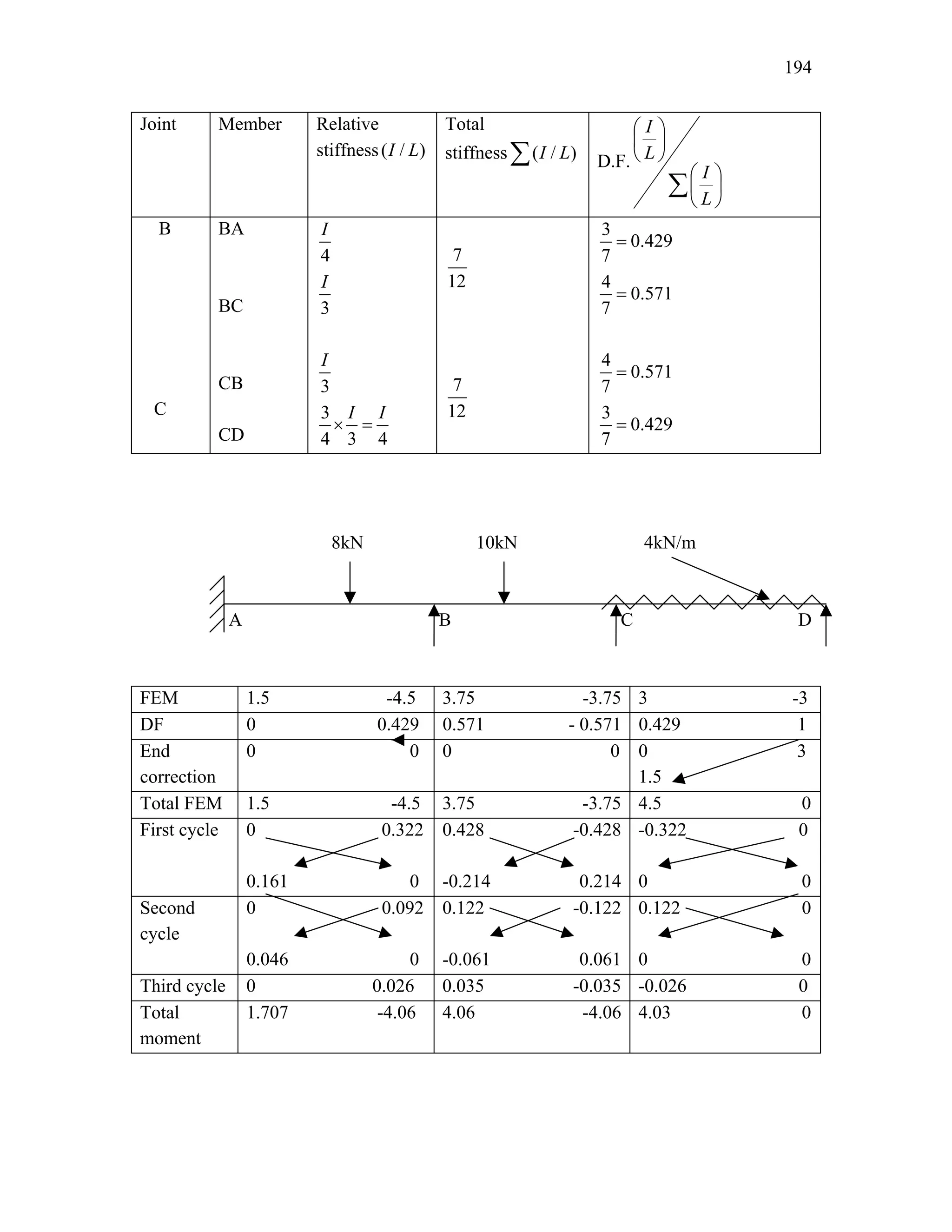

• Above assumptions convert indeterminate multi-storey frame to a determinate

structure

Steps involved in analysis of frame:

• Horizontal shears on each level are distributed between columns of that floor

• Moment in each column is equal to column shear multiplied by half the column height

• Girder moments are determined by applying moment equilibrium equation to joints

• Shear in each girder is equal to its moment divided by half the girder length

• Finally, column axial forces are determined by summing up beam shears and other

axial forces at each joint

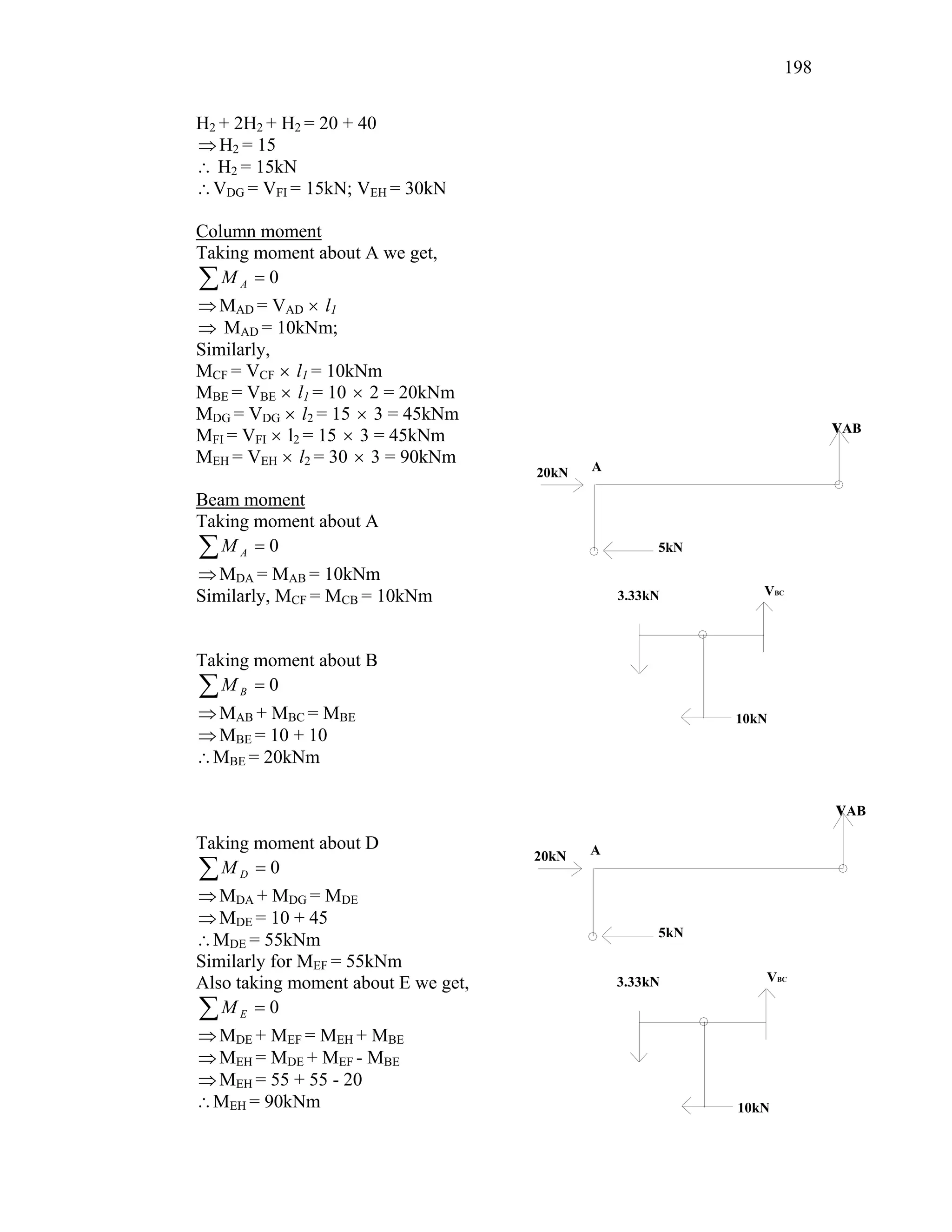

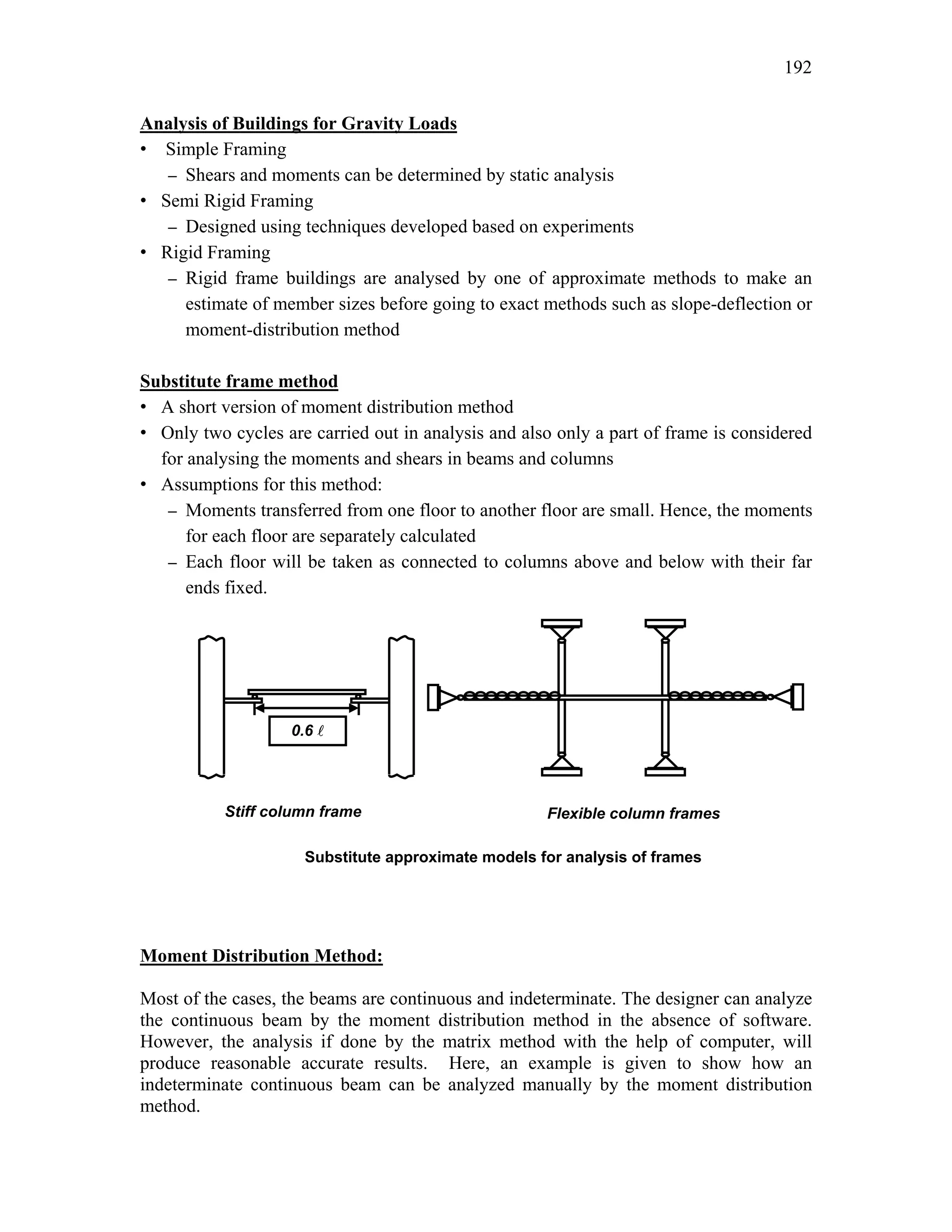

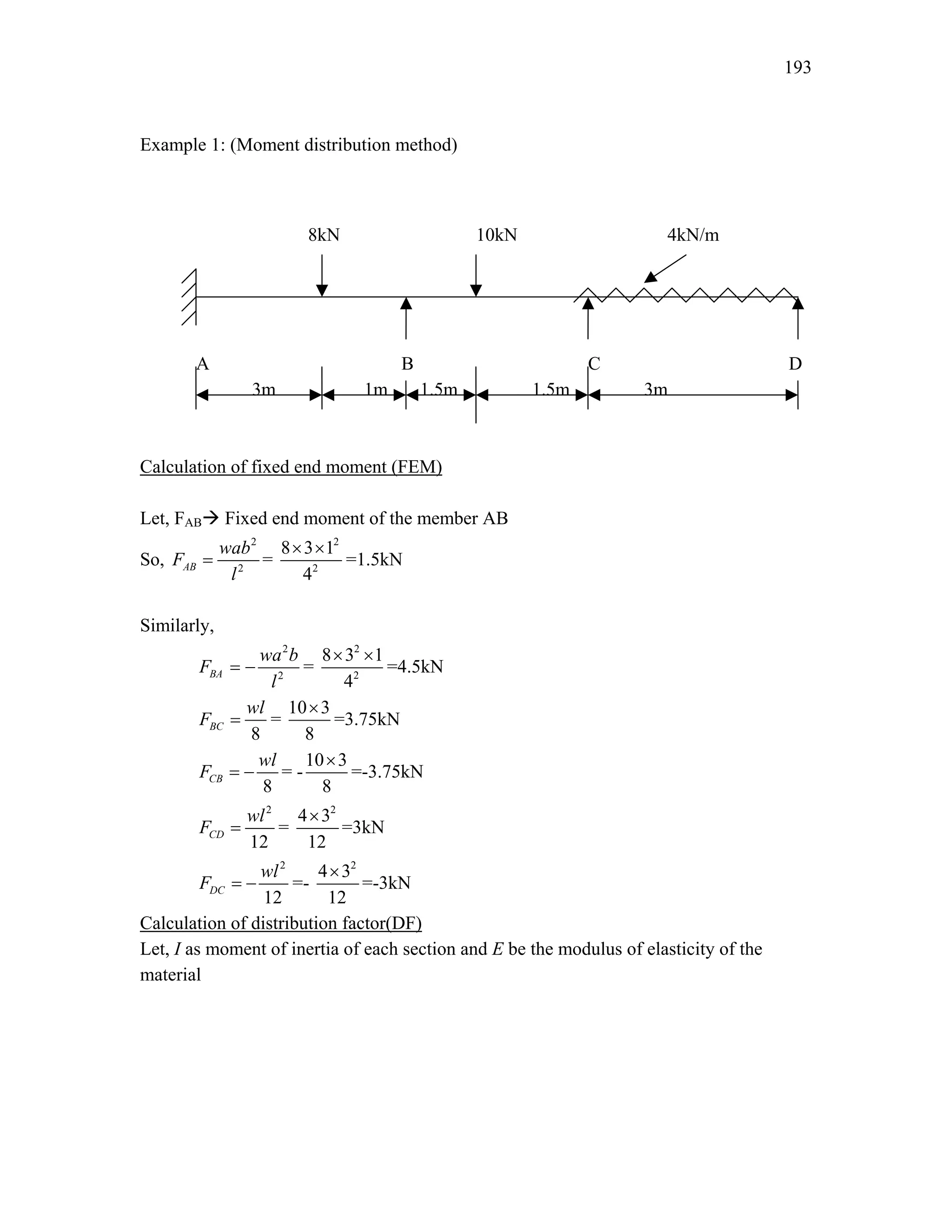

Example 2: (Portal method)

Analyze the frame given in the figure.

Column shear

Let, H1Æhorizontal shear at the member AD

So,

VAD = VCF = H1; VBE = 2H1 [As per assumption]

So, equating the horizontal forces we get,

H1 + 2H1 + H1 = 20

5

1 =

∴ H kN

∴VAD = VCF = 5kN; VBE =10kN

Let, H2Æhorizontal shear at the member DG

So,

VDG = VFI = H2; VEH = 2H2

Again, equating the horizontal forces we get,](https://image.slidesharecdn.com/compositestructure31-38-220911015532-e4f2815d/75/compositestructure31-38-pdf-38-2048.jpg)