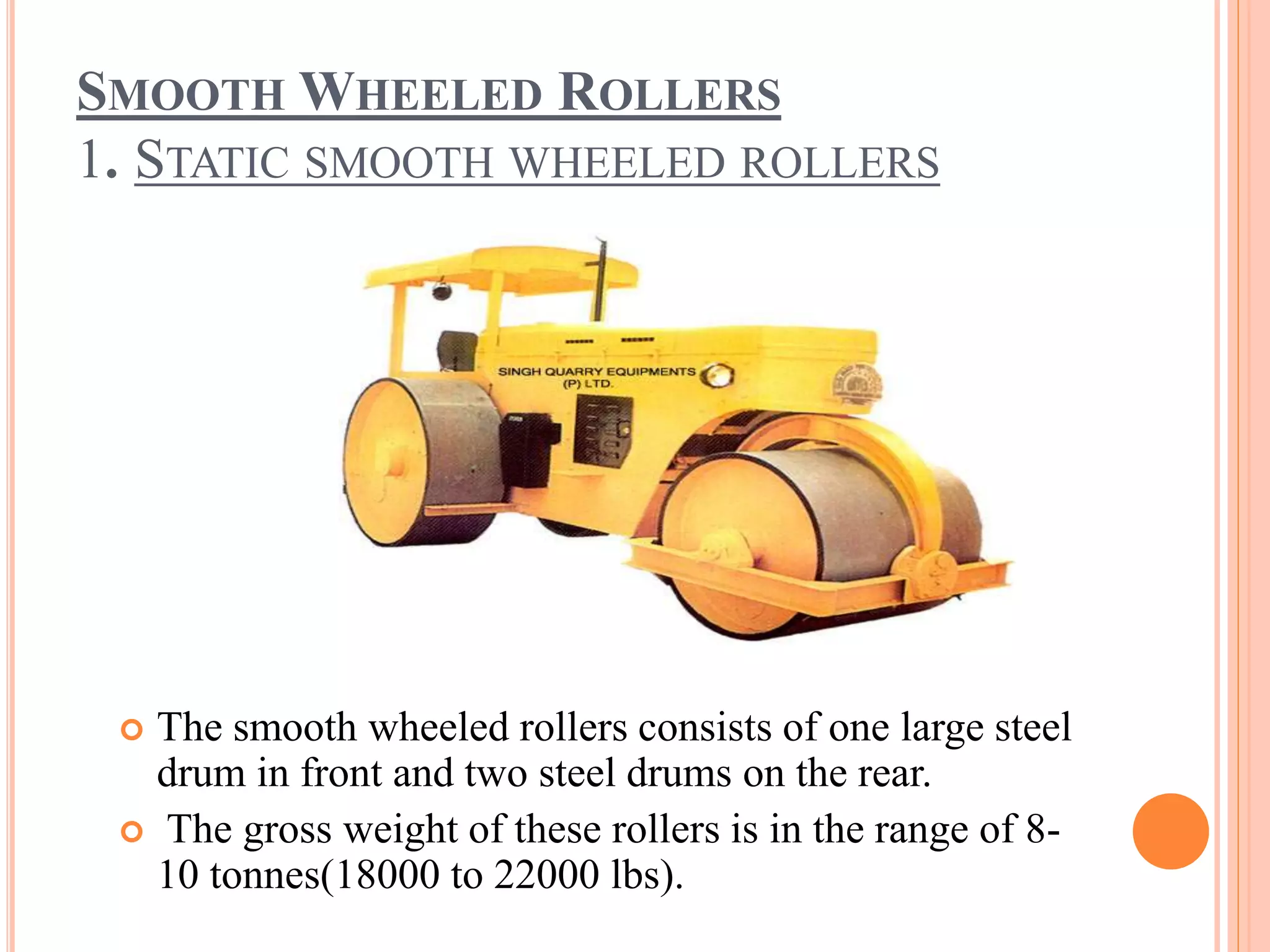

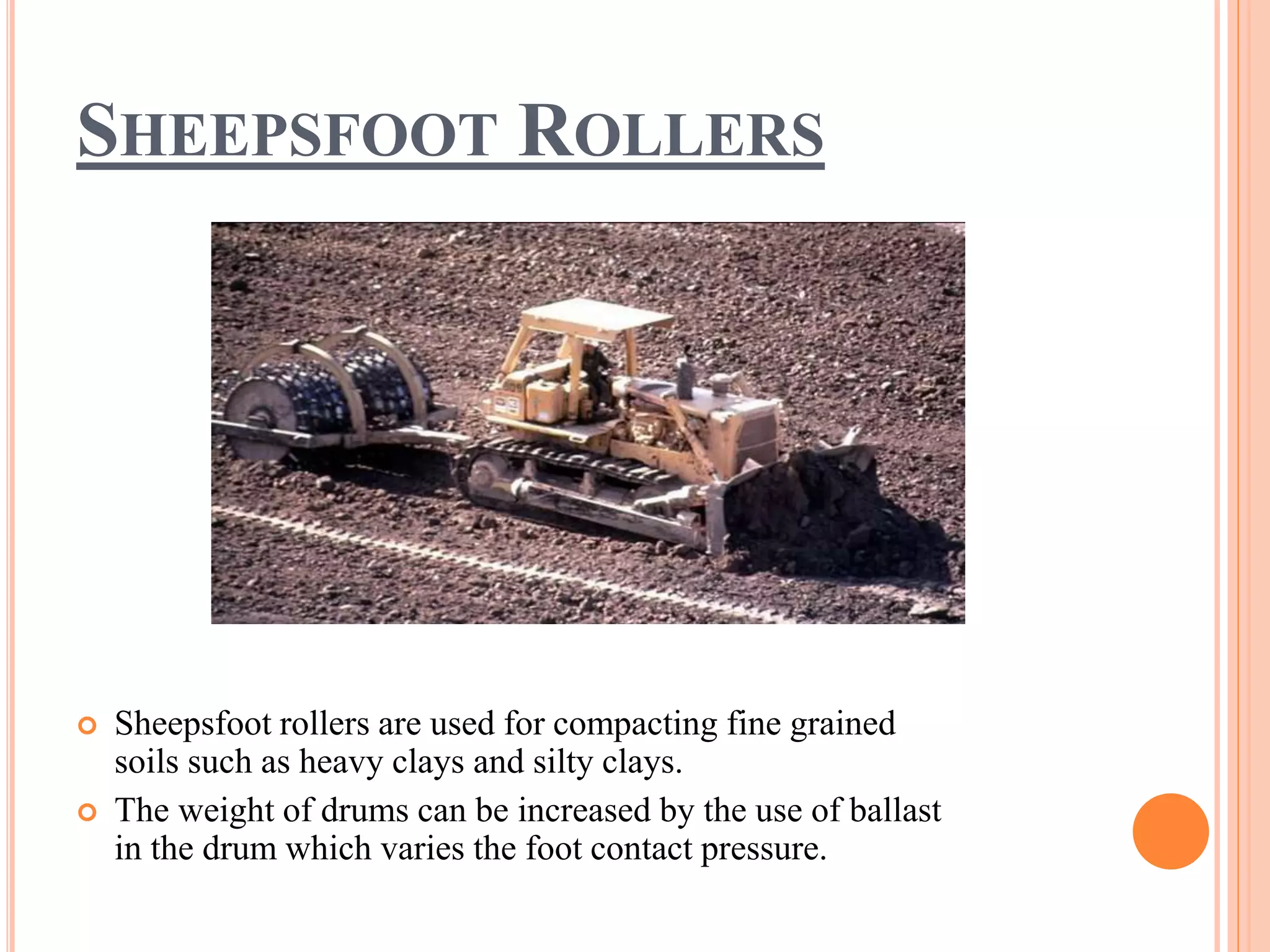

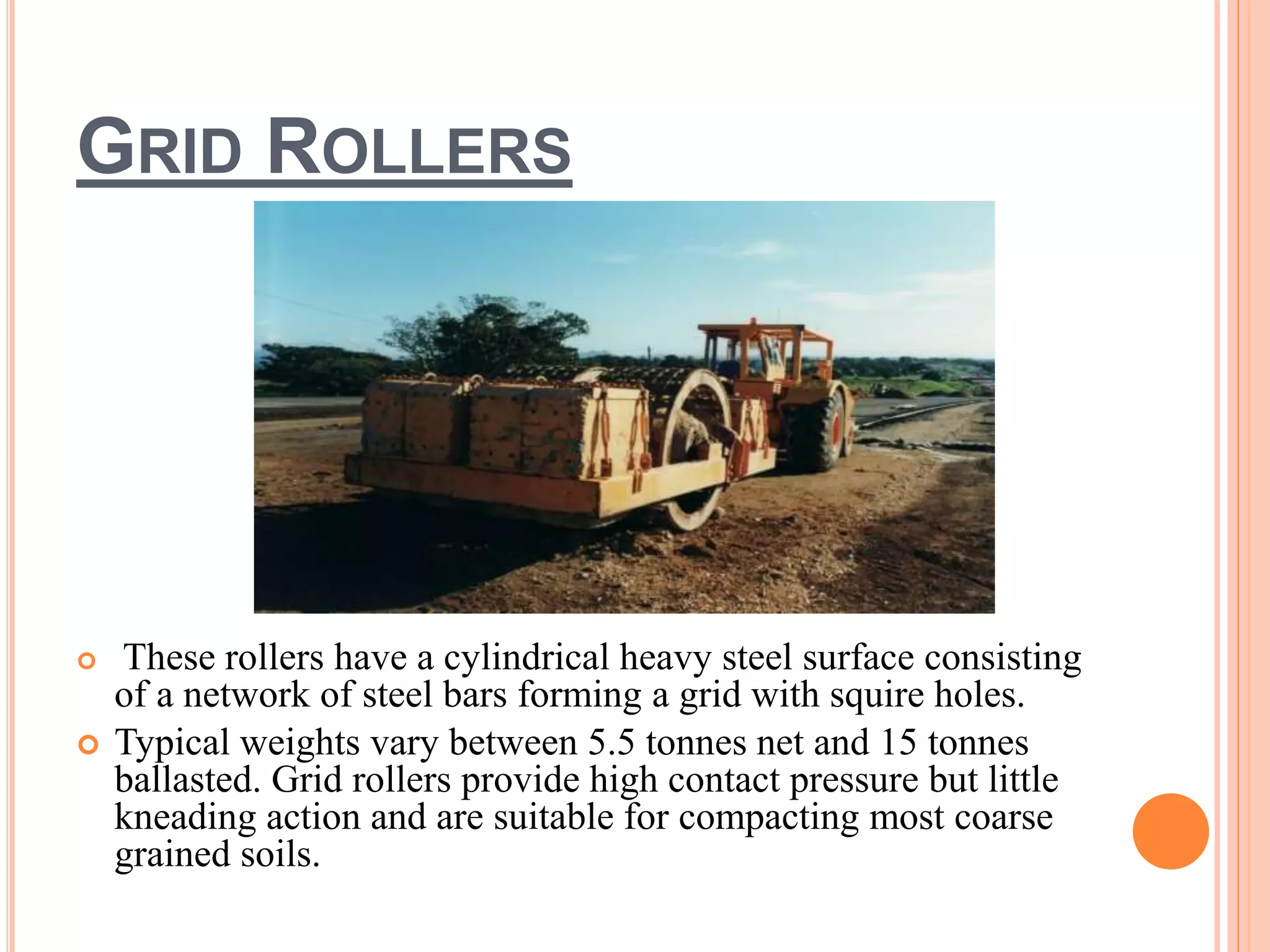

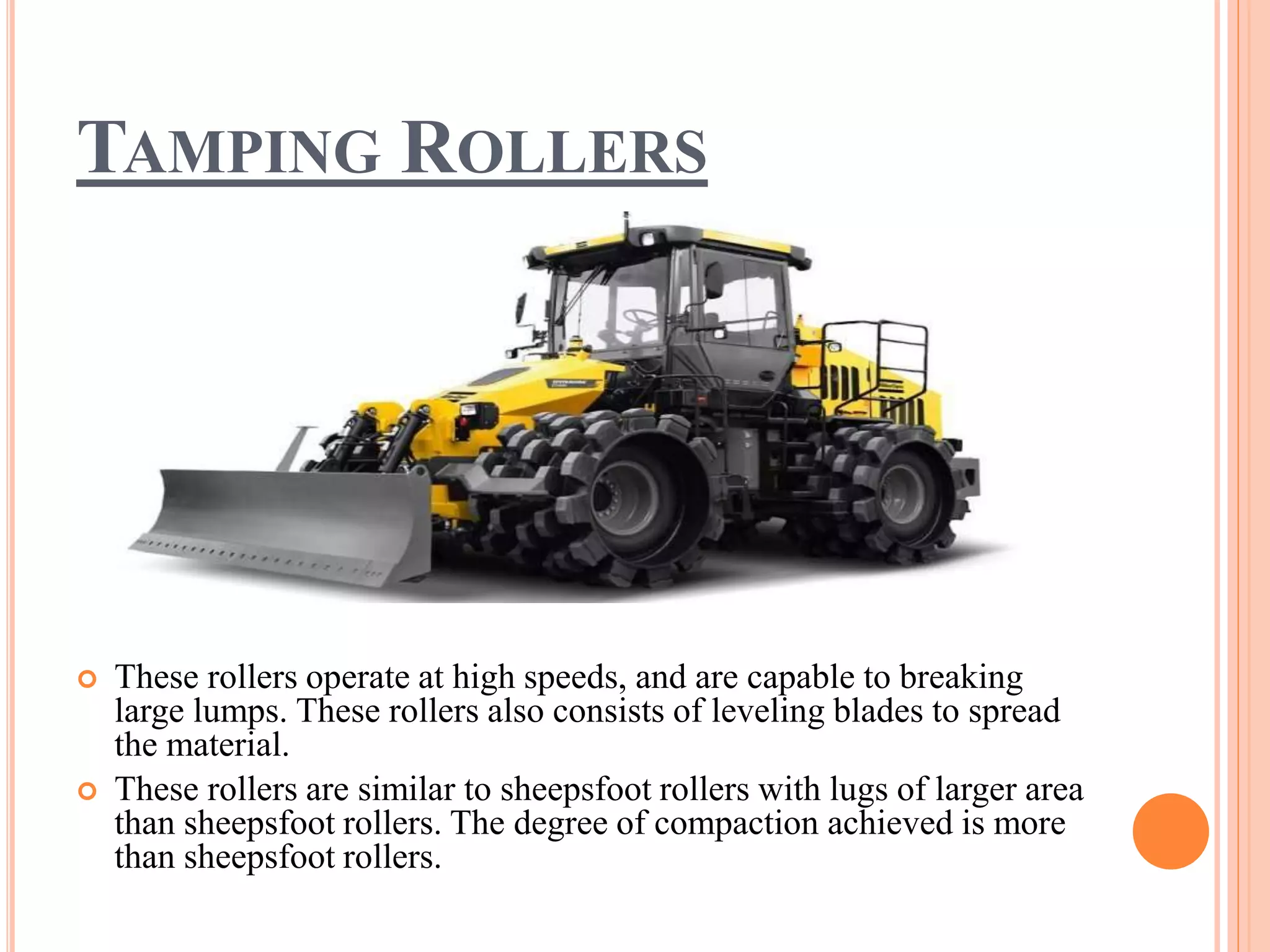

There are several types of rollers used for compacting soil and materials in construction. The main types are smooth wheeled, vibrating smooth wheeled, sheepsfoot, pneumatic-tired, grid, tamping, and padded drum vibratory rollers. Smooth wheeled rollers compact using static weight or vibration and come in single or dual drum models. Sheepsfoot rollers are used for compacting clay-based soils using foot contact pressure. Pneumatic rollers are effective on coarse-grained soils and their weight can be increased with ballasting. Grid rollers provide high contact pressure while tamping rollers can break up clumps at high speeds.