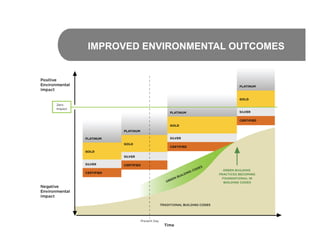

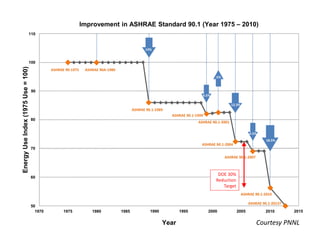

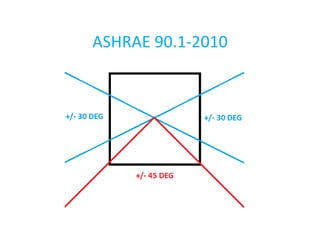

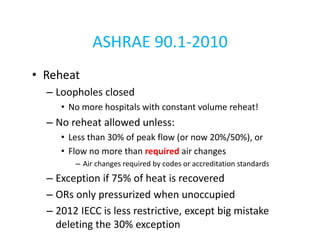

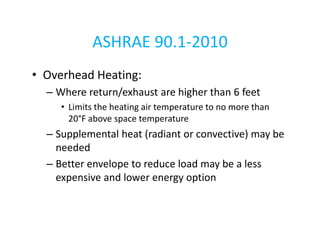

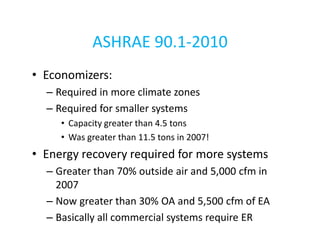

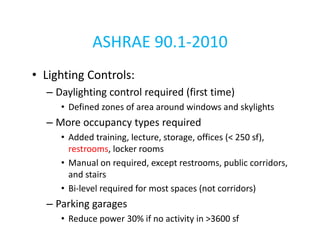

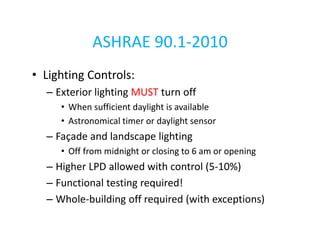

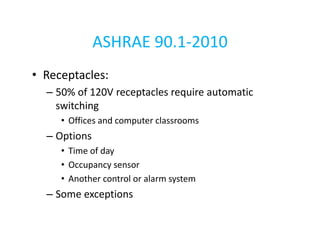

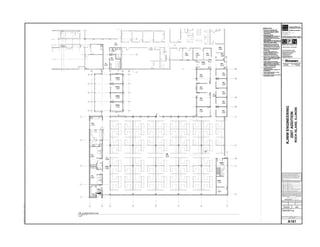

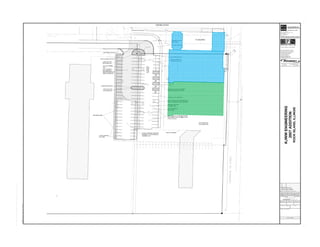

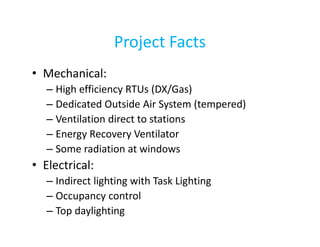

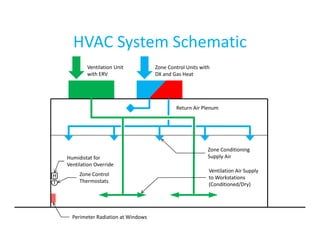

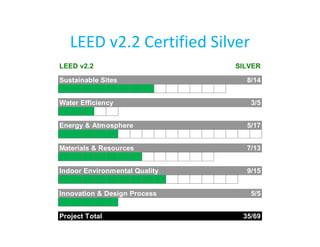

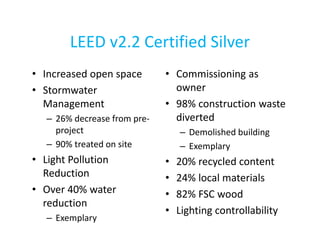

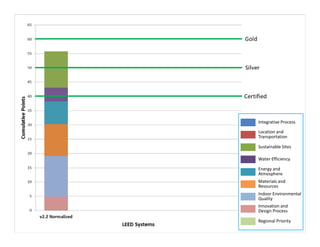

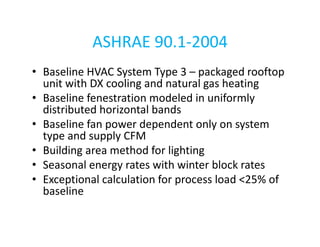

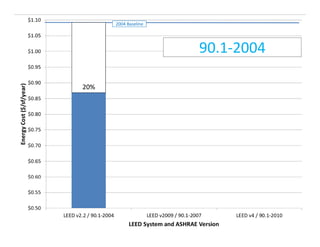

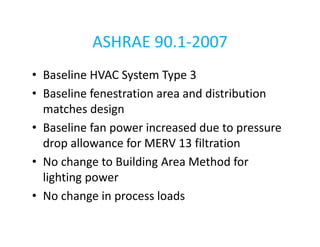

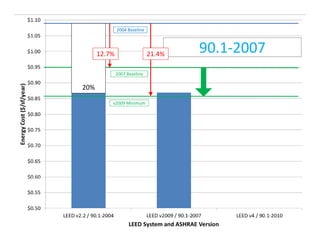

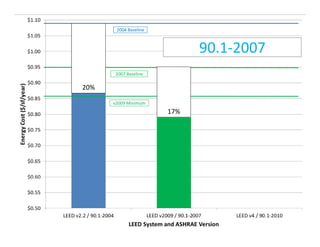

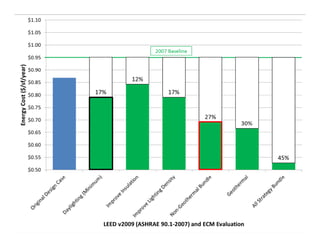

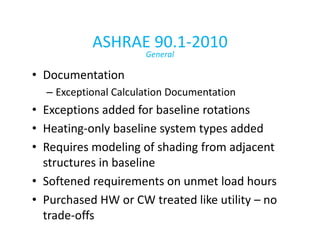

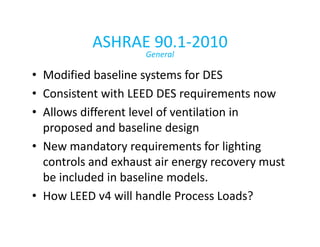

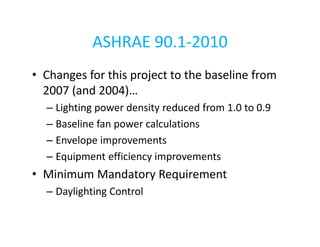

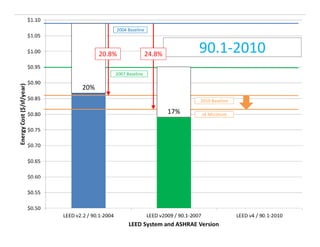

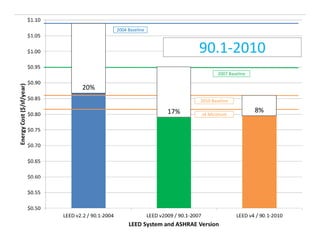

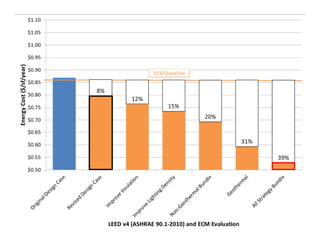

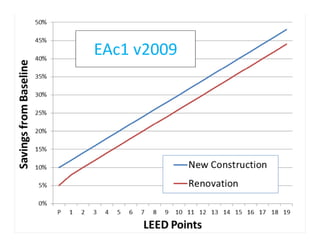

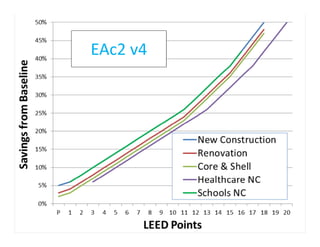

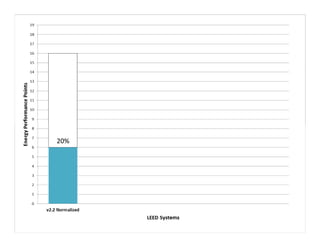

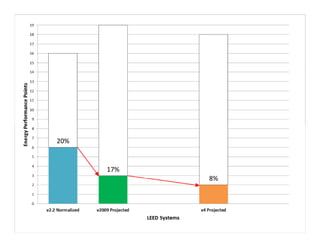

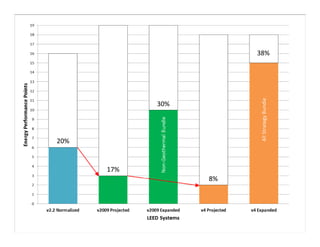

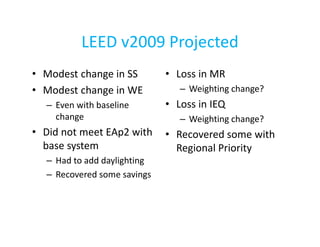

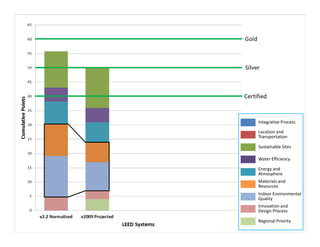

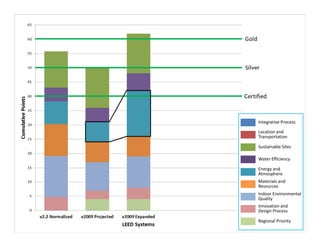

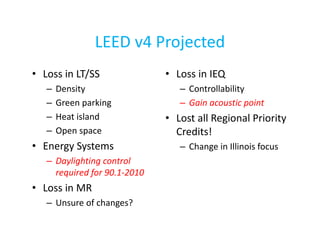

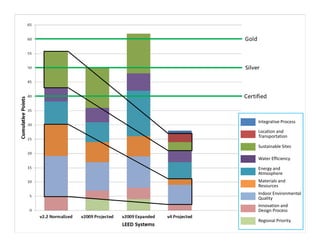

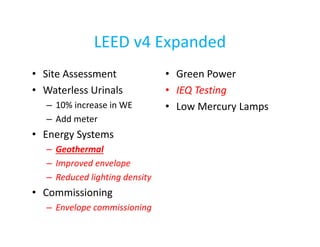

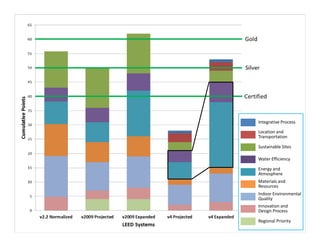

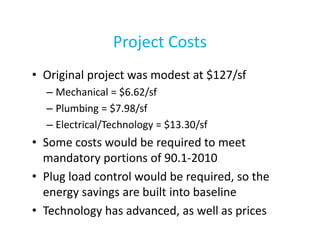

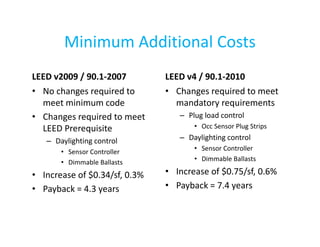

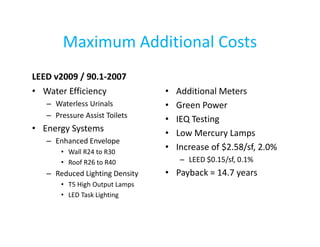

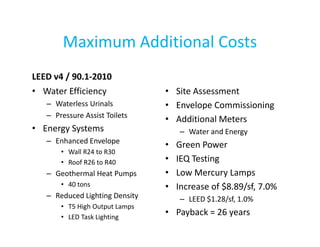

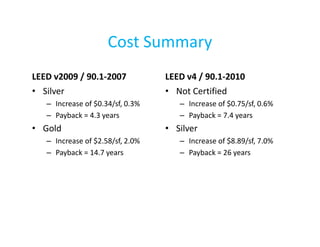

The document discusses the major changes in ASHRAE 90.1-2010 and their implications for energy modeling and LEED certification, highlighting the enhancements in building energy efficiency standards over the years. It emphasizes the need for design firms to educate clients about these evolving requirements and the importance of robust energy modeling to meet savings goals. Additionally, it details project specifications of the KJWW engineering consultants' expansion and outlines the associated costs and energy-saving strategies necessary for compliance with newer standards.