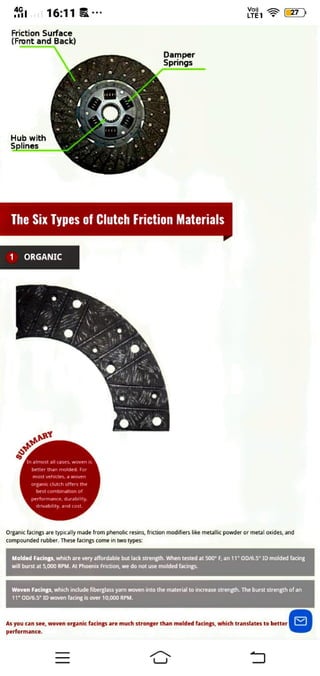

This document provides information on different types of clutch friction materials, including organic, heavy-duty organic, ceramic, Kevlar, feramic, and FeramAlloy materials. It discusses the characteristics of each type, such as temperature resistance, engagement smoothness, longevity, and best applications. Organic and heavy-duty organic materials are best for daily drivers and most street performance vehicles. Kevlar materials offer long lifespan and smooth engagement but lower torque capacity. Ceramic and feramic materials are only suitable for racing due to their abrupt engagement. Carbotic and FeramAlloy materials are designed for heavy-duty applications like commercial trucks.