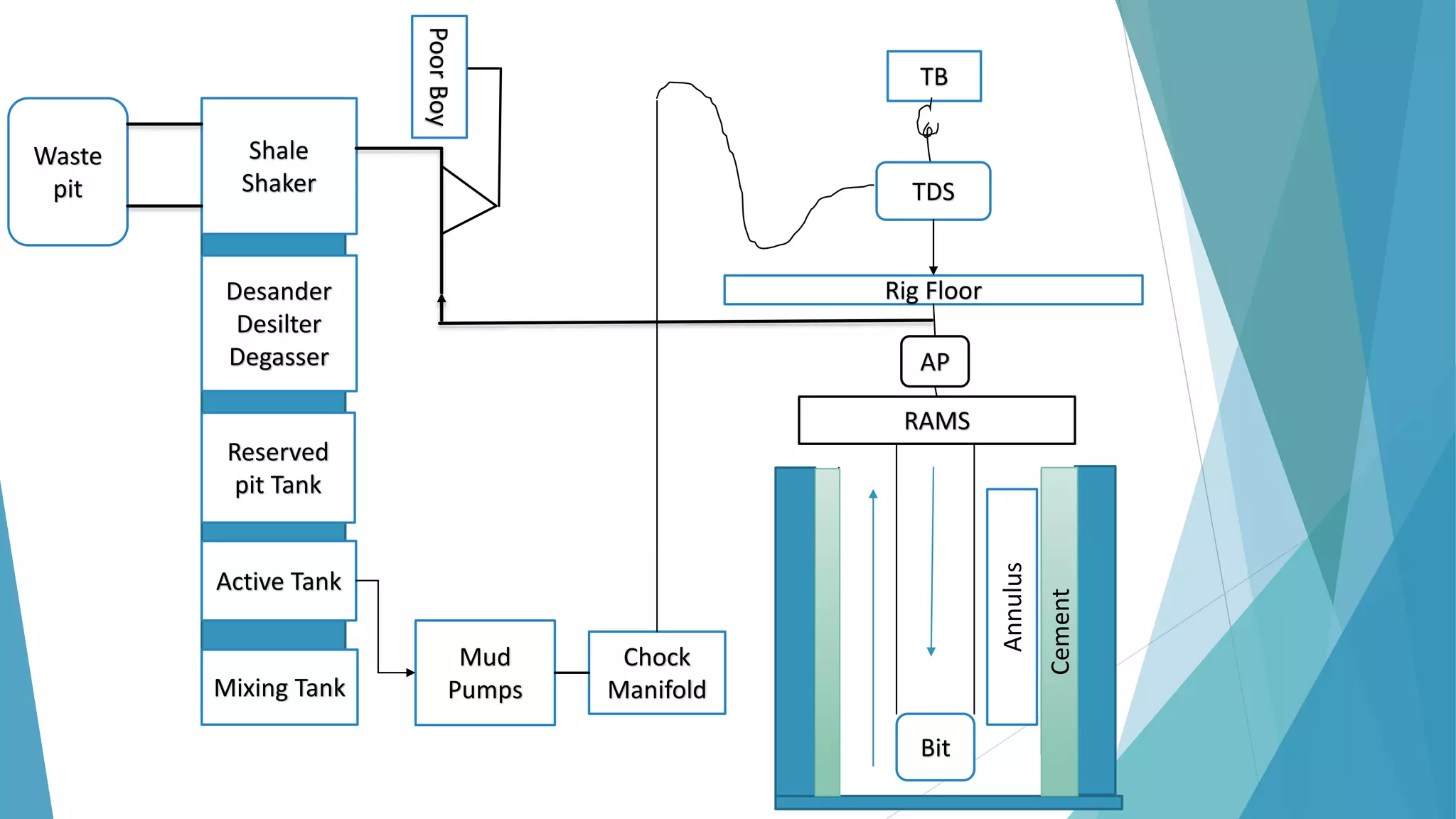

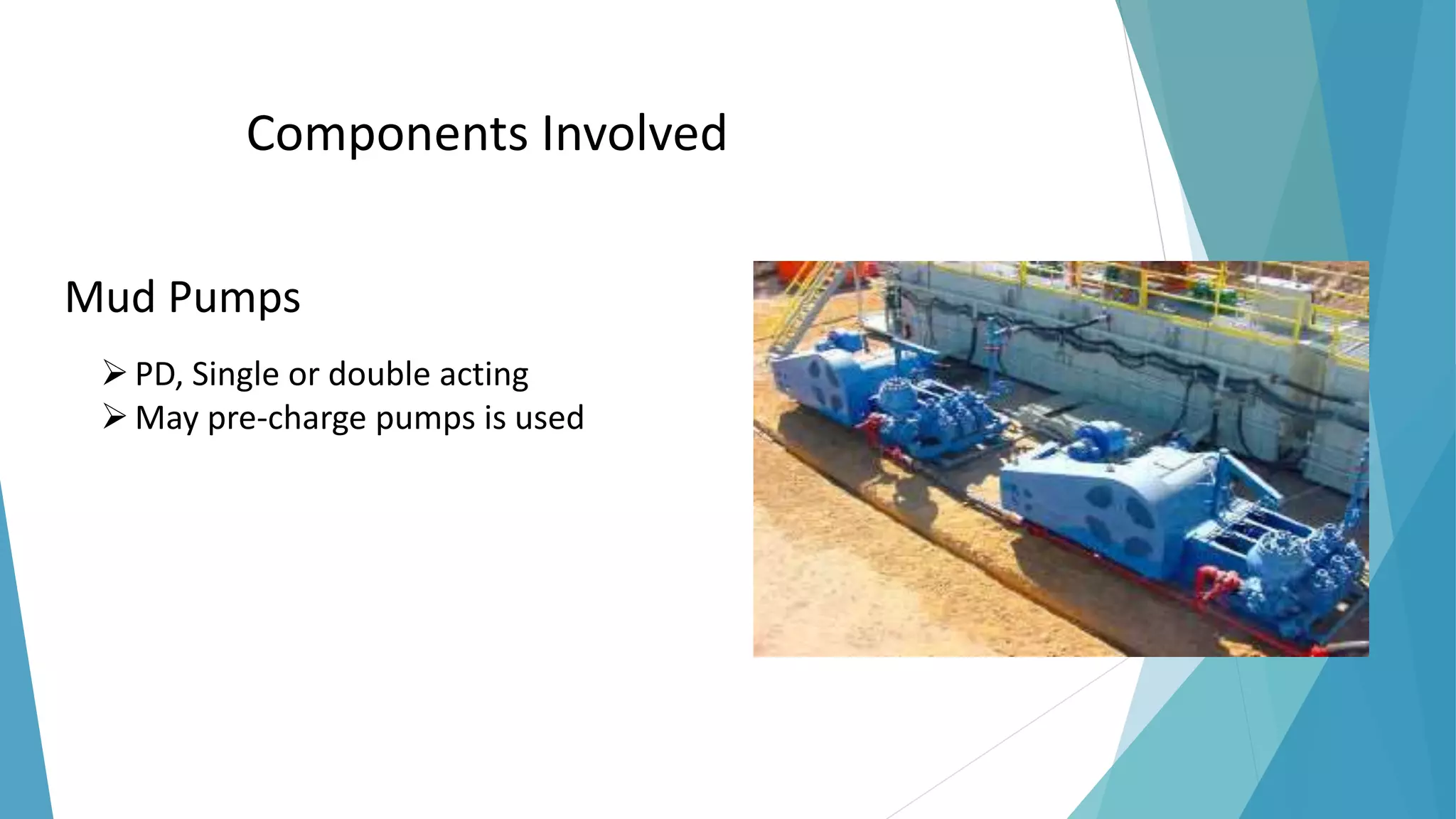

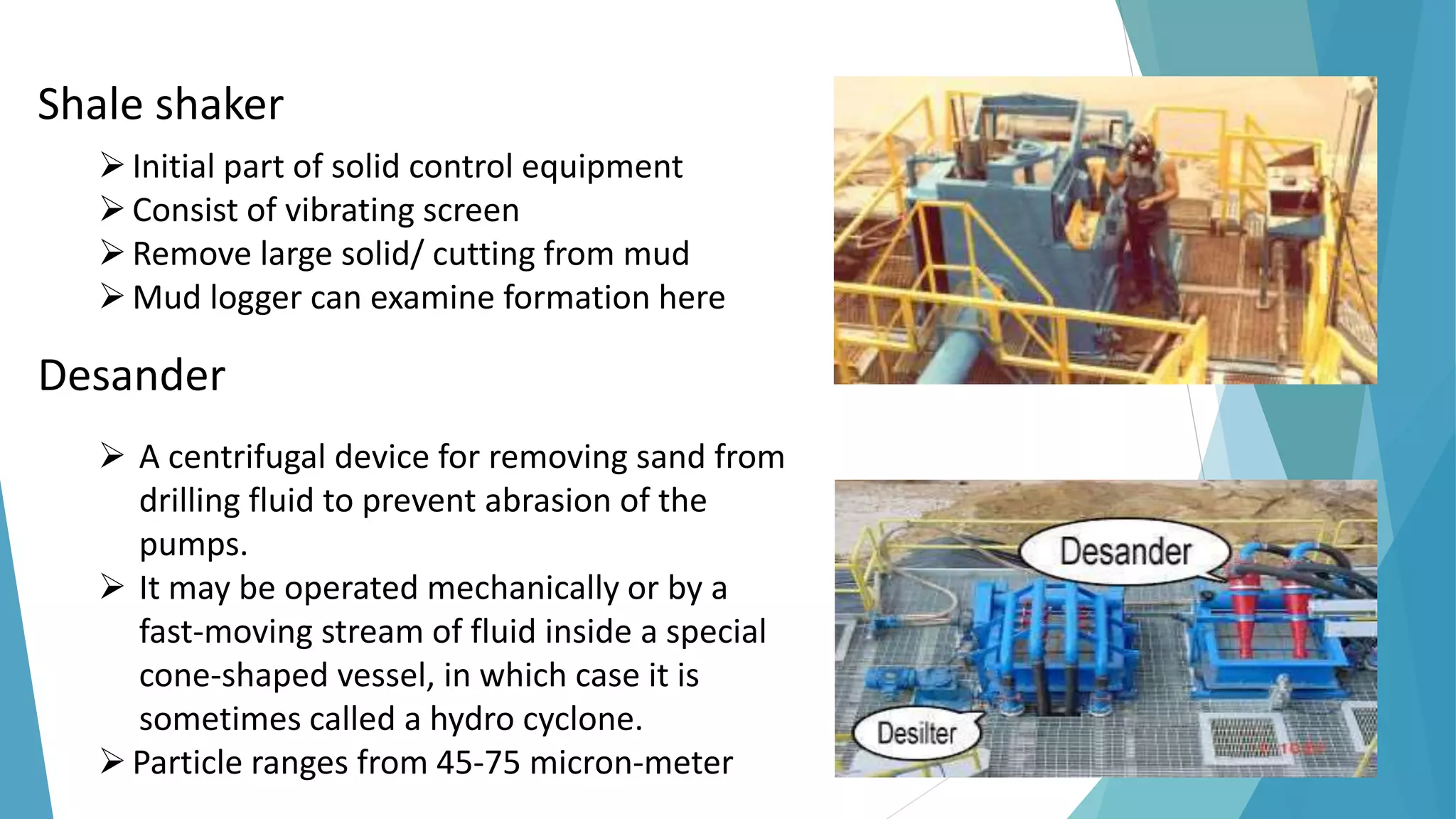

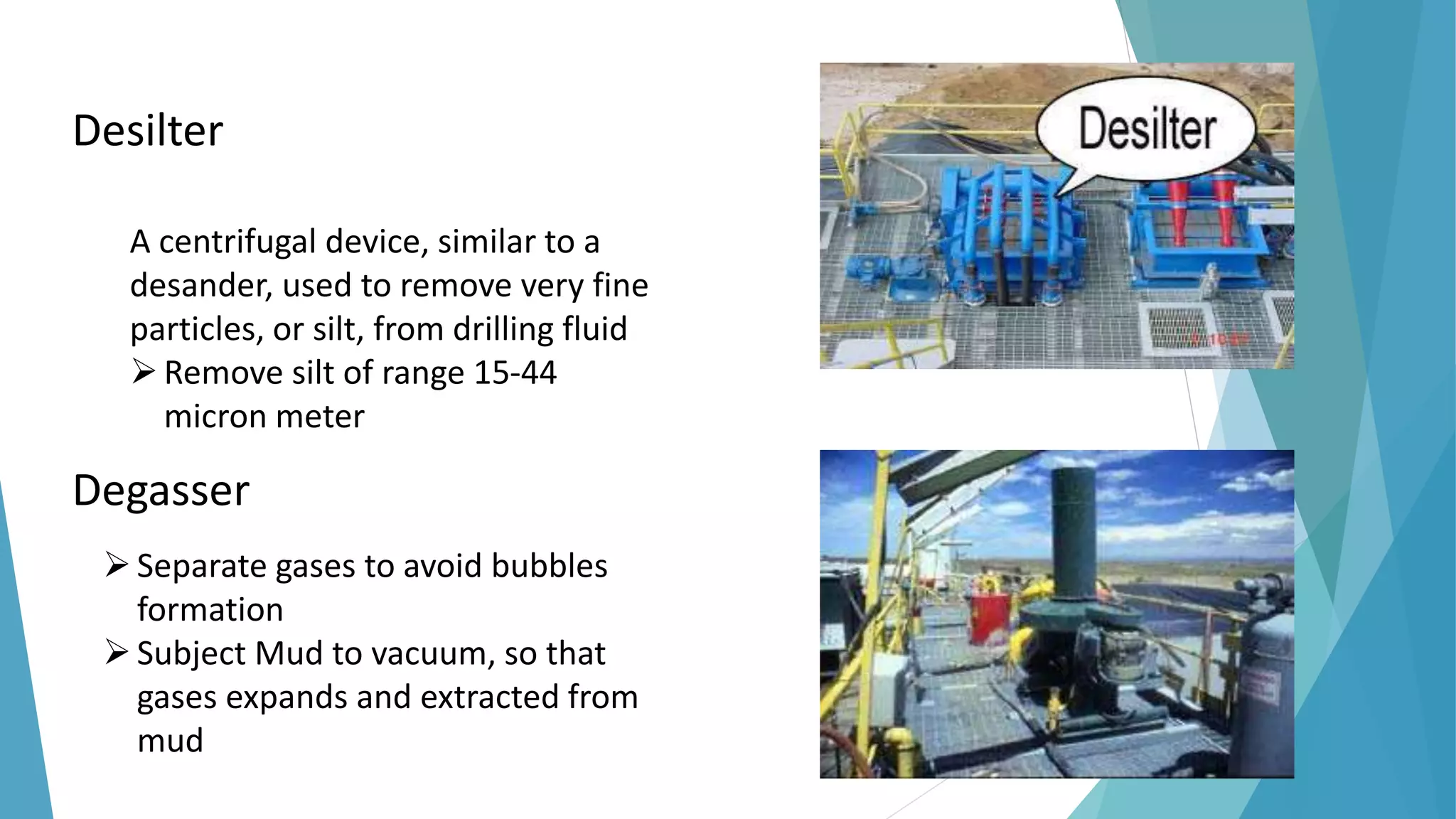

The rig circulatory system circulates drilling mud through the drill string and up the wellbore to carry cuttings to the surface and cool and lubricate the drill bit. Key components include mud pumps, shale shakers to remove cuttings from the mud, desanders and desilters to remove larger and finer particles, and degassers to remove gases from the mud before recycling it down the well. Different types of mud like water-based and oil-based are used depending on the formation being drilled.