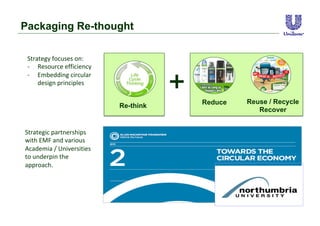

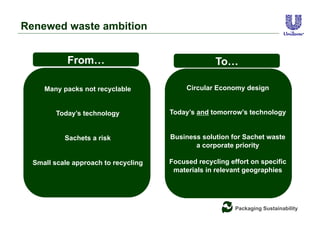

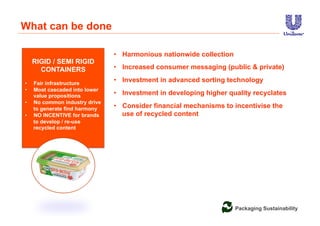

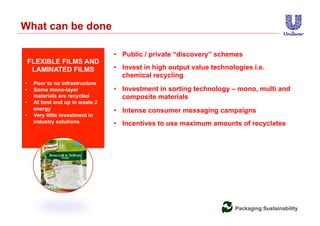

This document discusses moving towards a circular economy for plastics. It outlines the current challenges with different types of plastic packaging, including flexible films and laminated plastics which have poor recycling infrastructure. For rigid bottles and containers, it notes there is infrastructure but no incentives for brands to use recycled content. It proposes solutions like advanced sorting technology, harmonized collection, and incentives to increase recycling rates and use of recycled materials. Overall the document advocates for systems changes, new business models, improved reverse logistics, and designing packaging for circularity.