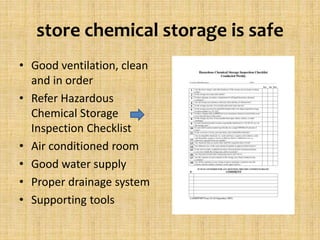

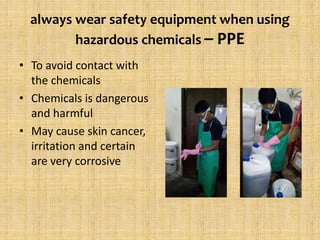

This document outlines a Chemical Hazard Risk Assessment (CHRA) process. The CHRA aims to ensure safety from harmful chemicals before, during, and after jobs. Key steps in the CHRA include ensuring safe chemical storage, purchasing chemicals that have safety data sheets, registering chemicals used, labeling chemicals used daily, wearing protective equipment when using hazardous chemicals, providing safety training twice yearly, and recording intake of hazardous chemicals from storage.

![safety training using harmful chemicals are

always done at least twice a year

• TRAINING PLAN FOR YEAR 2014

• The Training Programme / Topics for your

F&B Stewarding Department for the year

2014:-

Date Time Topics Department

• 29/5/2014

• [Thurs] 10.00am Science of Cleaning/

Chemical Knowledge F&B

• 29/5/2014

• [Thurs] 3.00pm Ware washing Procedures F&B

• 18/12/2014

• [Thurs] 10.00am Science of Cleaning/

Chemical Knowledge F&B

• 18/12/2014

• [Thurs] 3.00pm Ware washing Procedures F&B](https://image.slidesharecdn.com/1ef36b1f-5c4b-4344-9692-100e59598564-150406083003-conversion-gate01/85/CHRA-PPE-2-16-320.jpg)