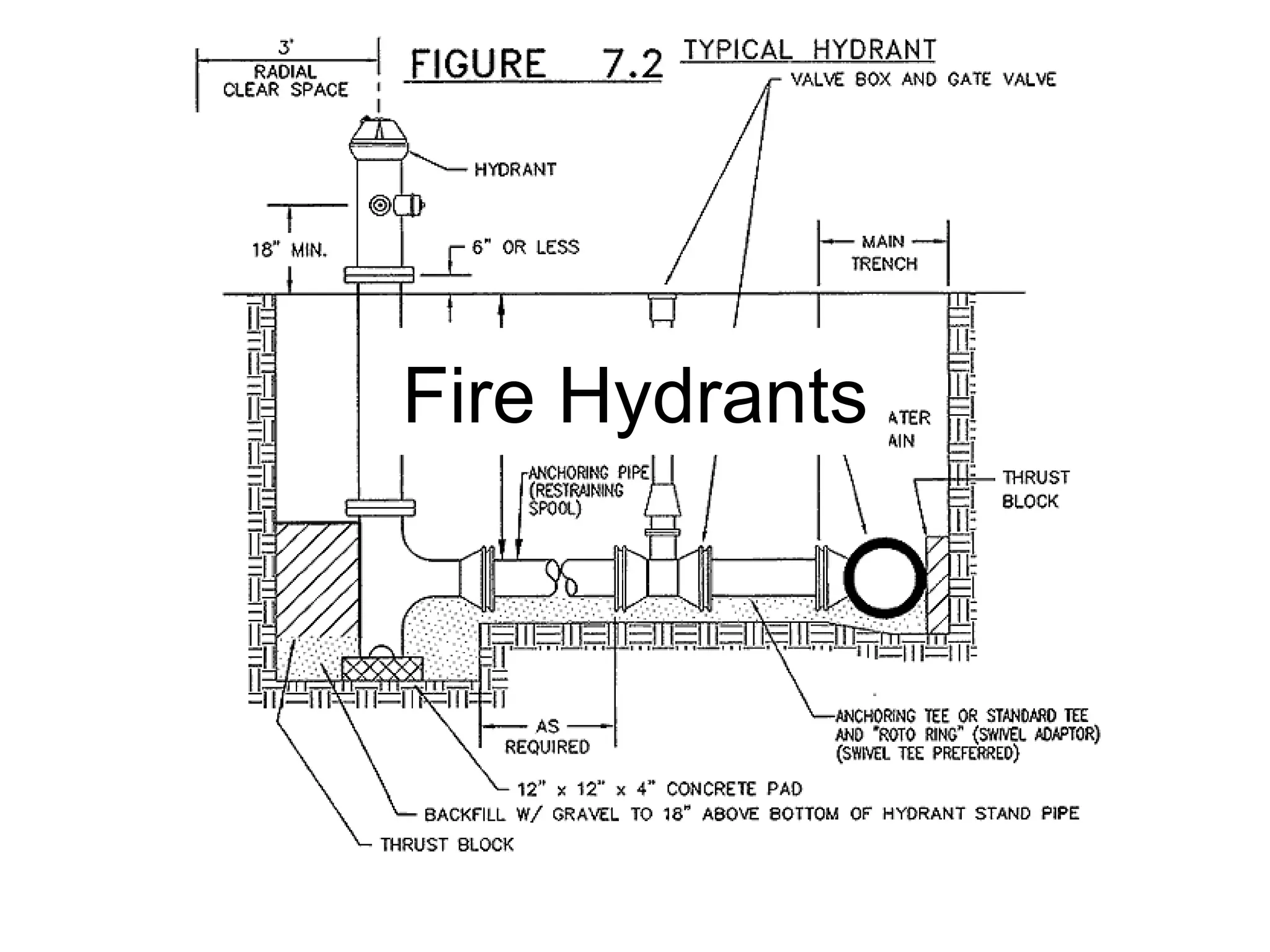

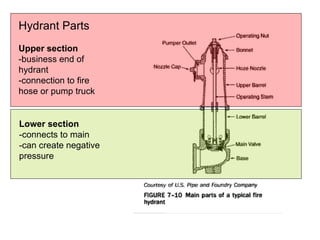

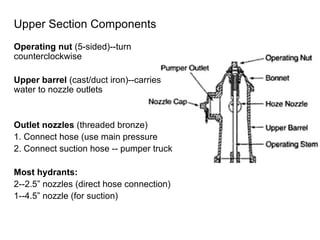

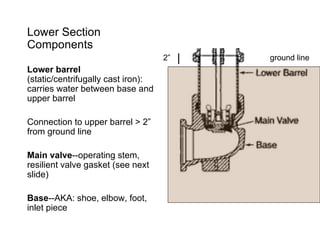

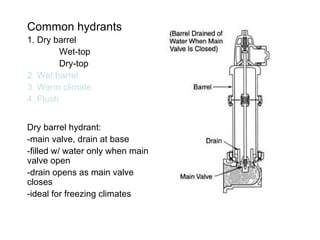

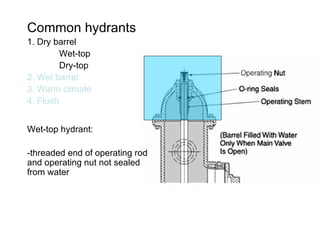

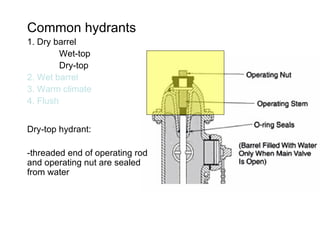

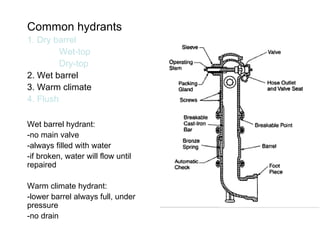

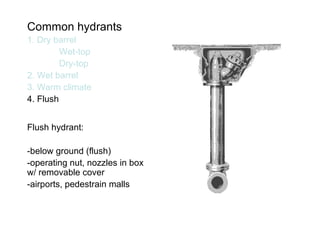

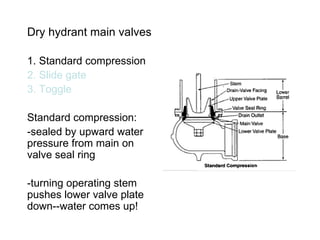

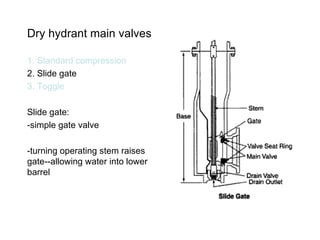

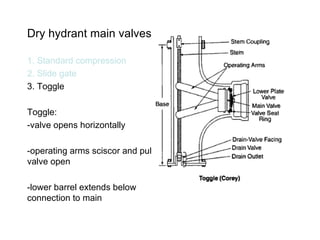

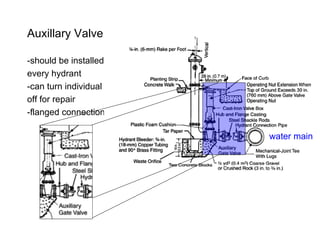

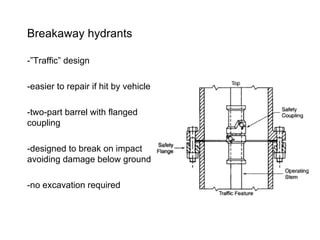

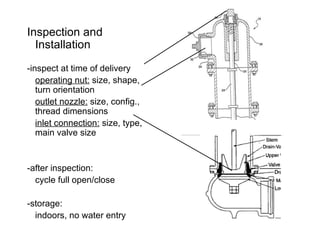

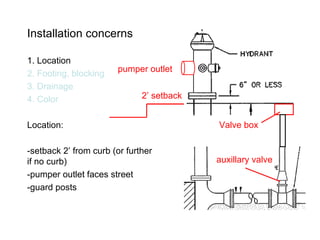

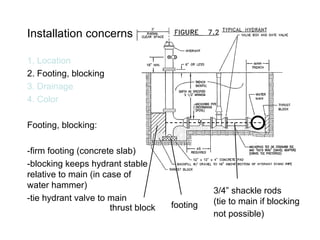

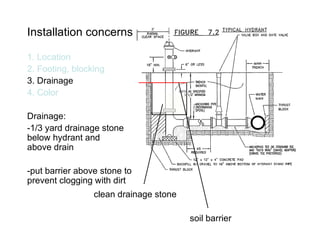

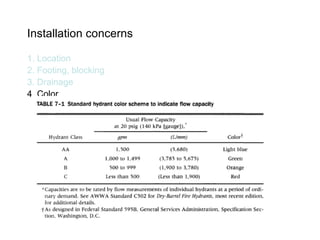

Fire hydrants have several key components and uses. The upper section includes outlets that connect to hoses for firefighting. The lower section connects to water mains and contains a main valve. There are different types of hydrants like dry barrel for freezing climates and wet barrel that are always full of water. Proper installation is important, making sure the hydrant has good footing and drainage, is visible to crews, and can be easily accessed and operated during an emergency. Routine maintenance like inspections helps ensure hydrants remain functional.