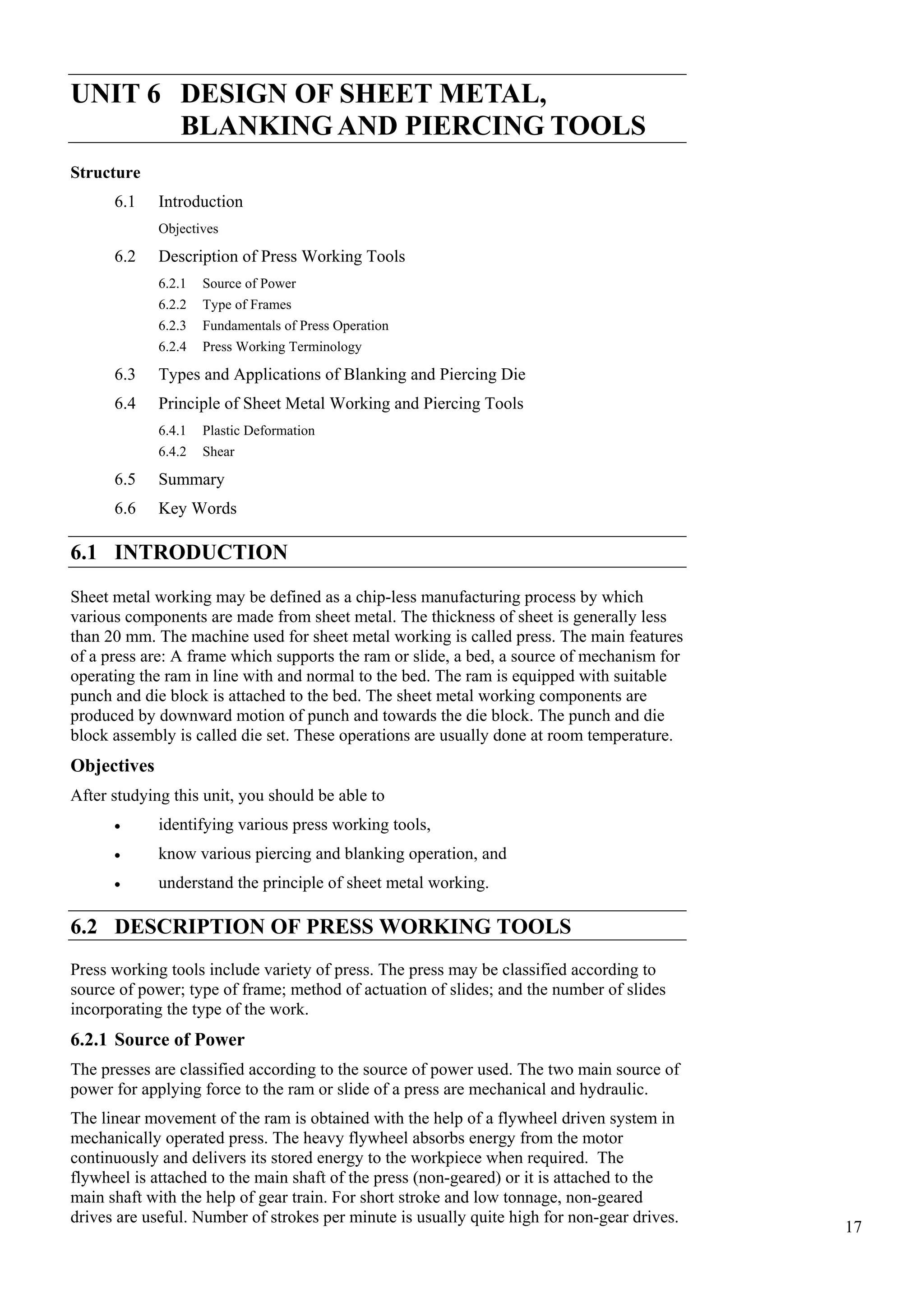

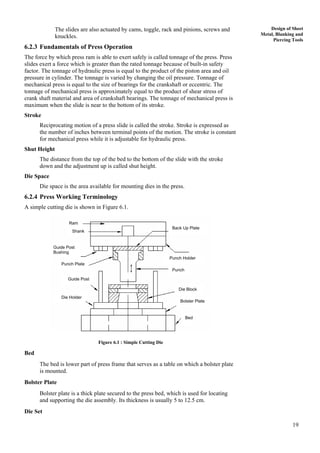

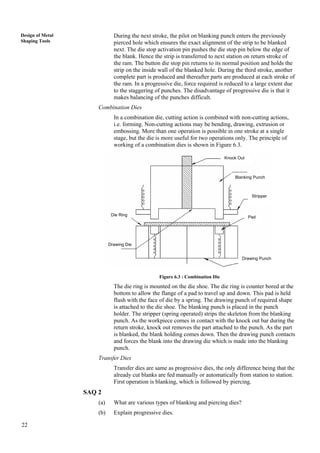

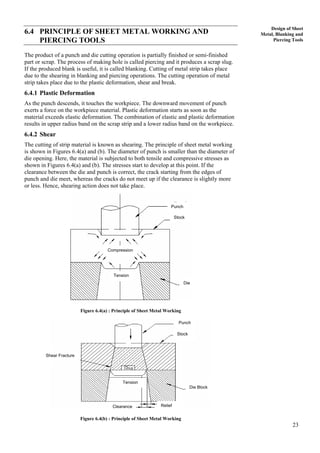

This document discusses sheet metal working tools and presses. It begins by defining sheet metal working as a chip-less manufacturing process for making components under 20mm thick from sheet metal, using a machine called a press. Presses are then classified based on their power source (mechanical or hydraulic), frame type (gap or straight side), number of slides (single, double, triple action), and actuation method (crankshaft, eccentric, etc.). Key press components like the bed, bolster plate, die set, punch, and stripper are also defined. Blanking and piercing dies are introduced, with dies classified by operation type (cutting vs. forming) and method of operation. The objectives are to identify various press