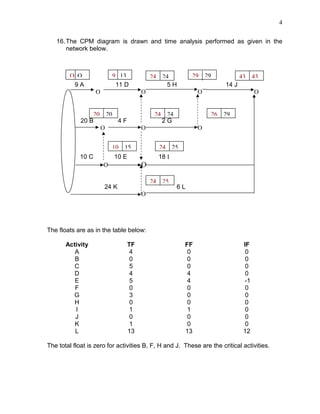

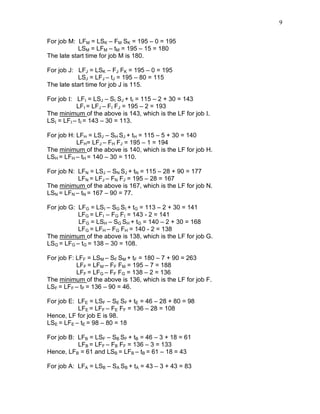

This document contains responses to questions about project management. It discusses key aspects of project organization including temporary job assignments, a command structure with flexibility, and good information flow. It also covers work breakdown structures, resource constraints, critical path analysis, float utilization, and updating project schedules as new information becomes available.