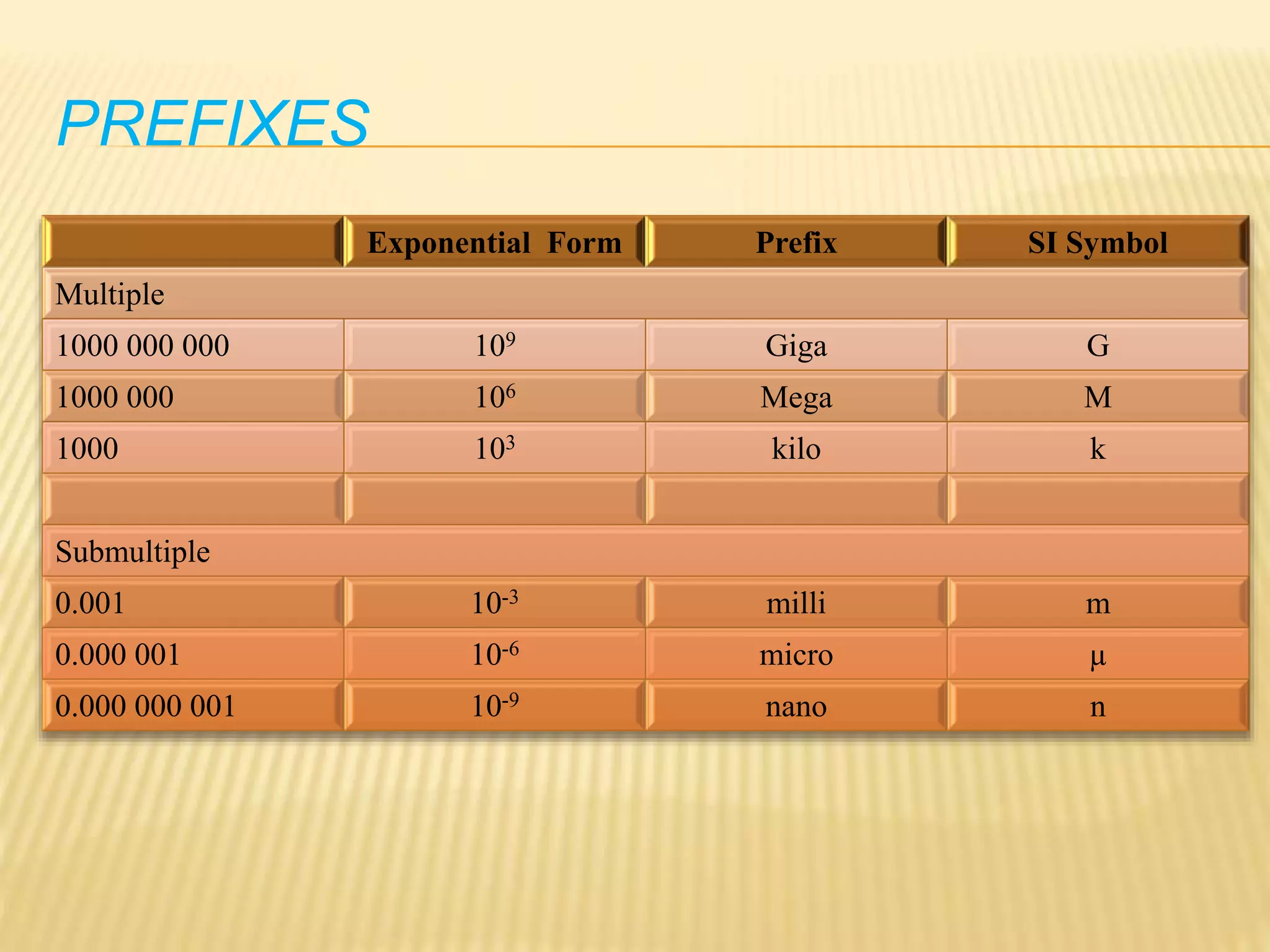

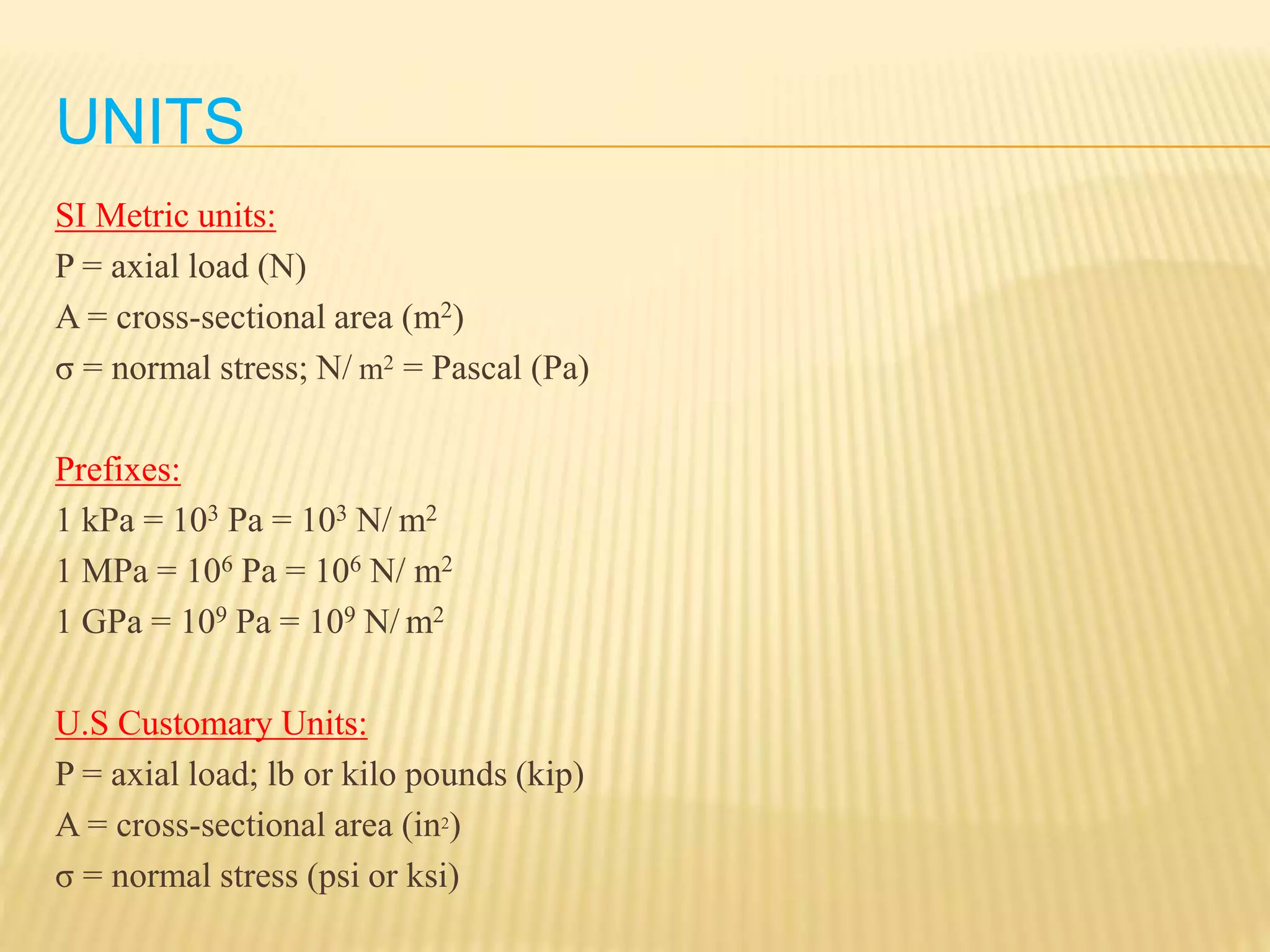

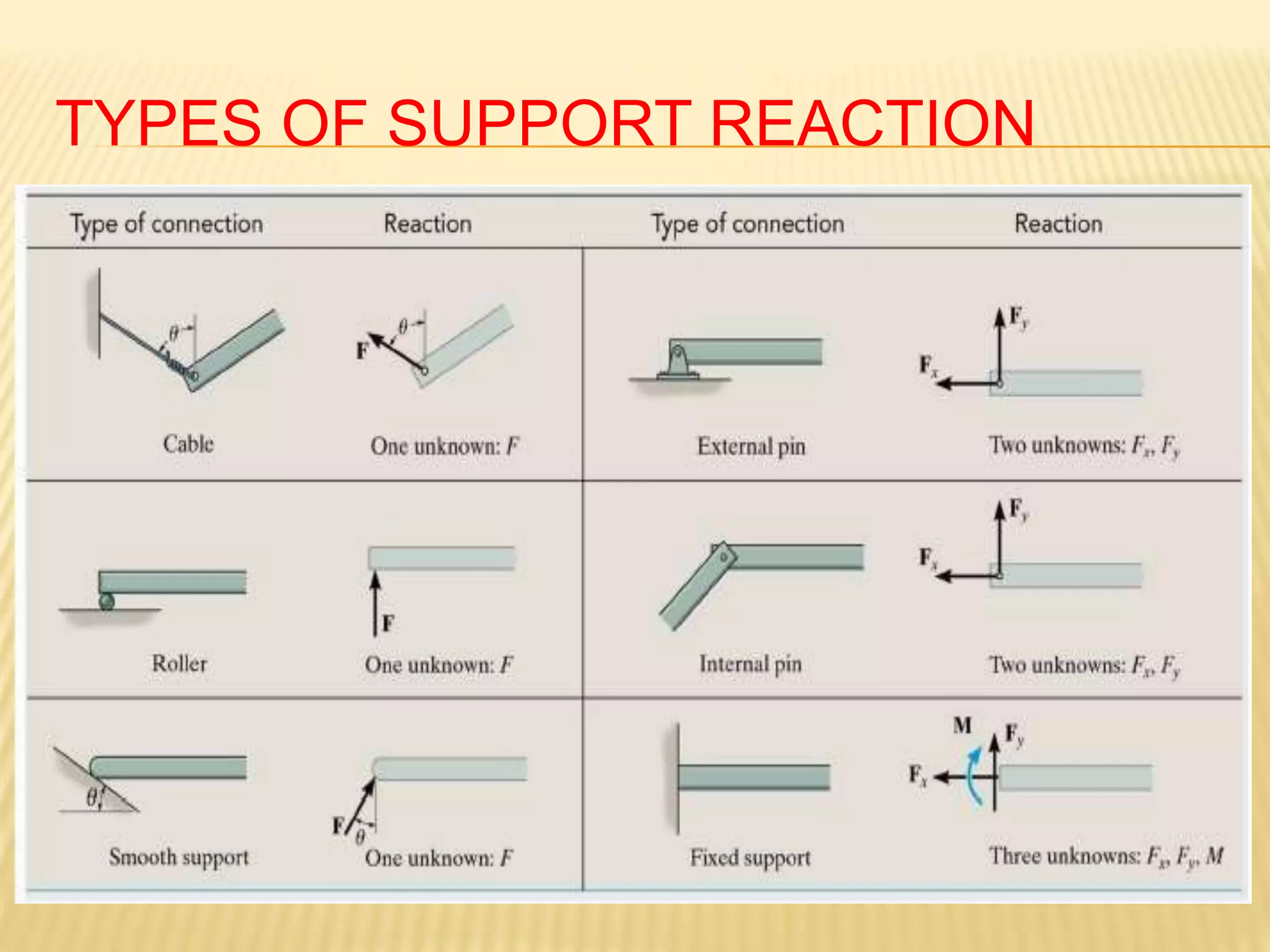

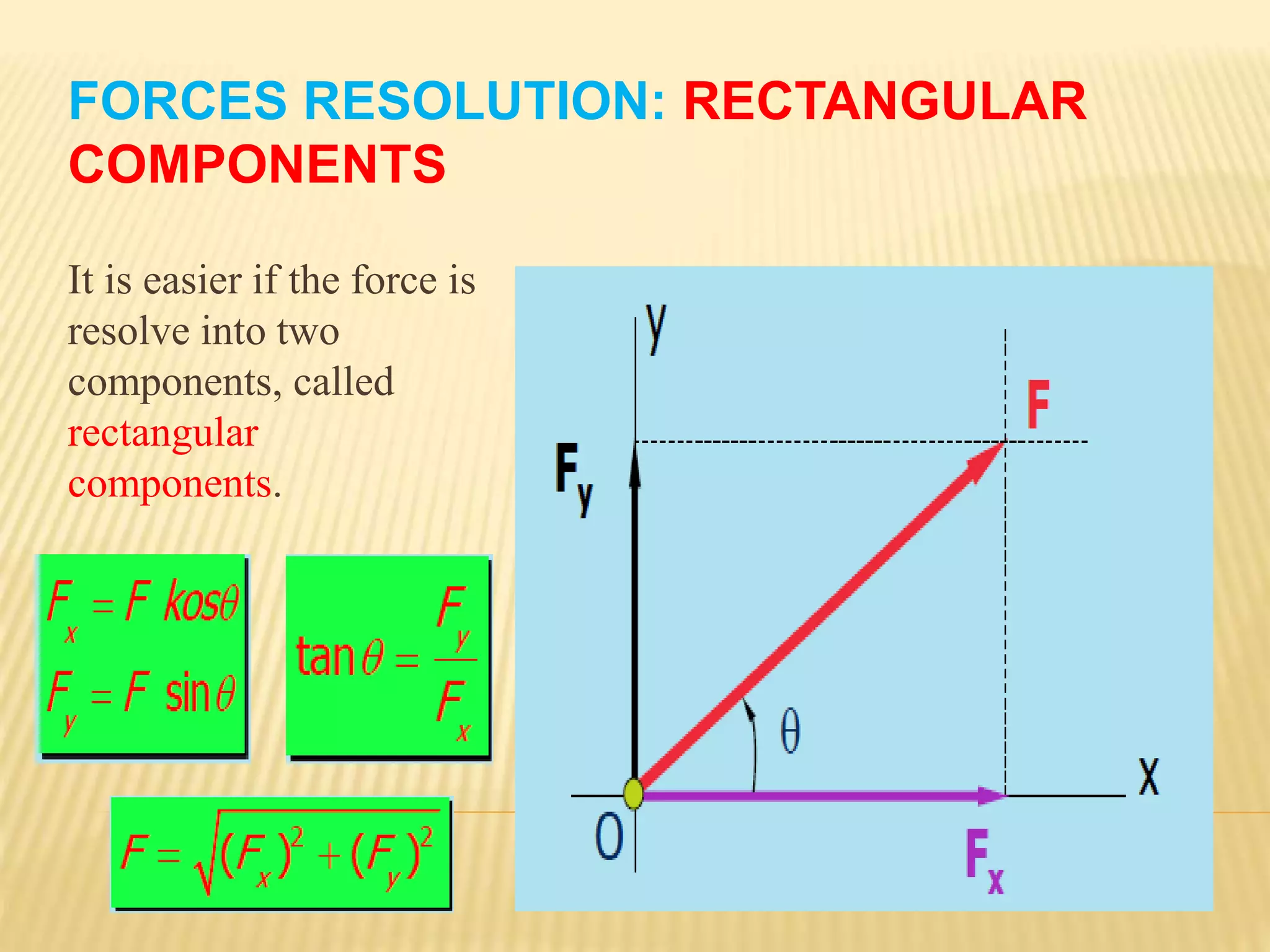

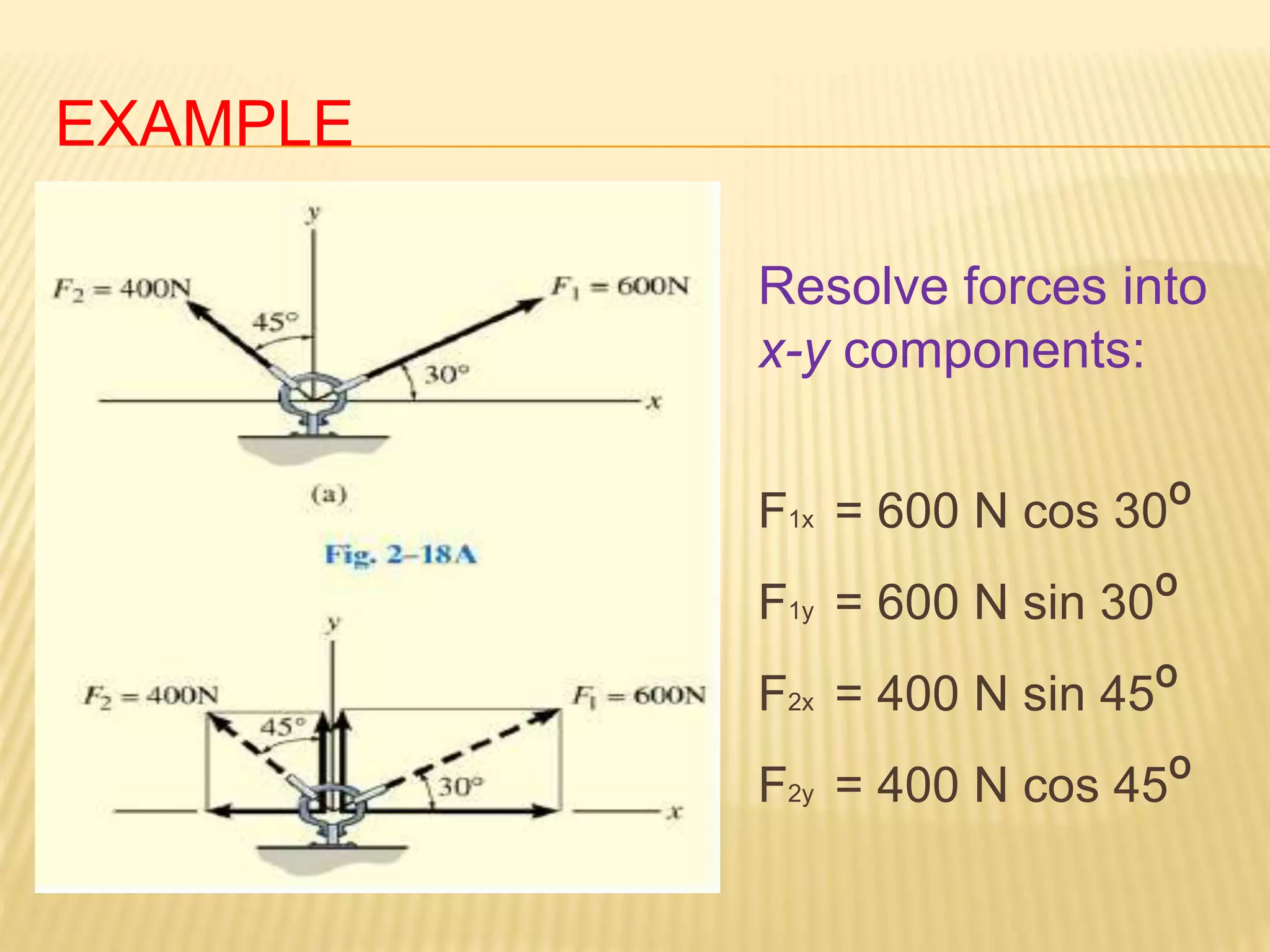

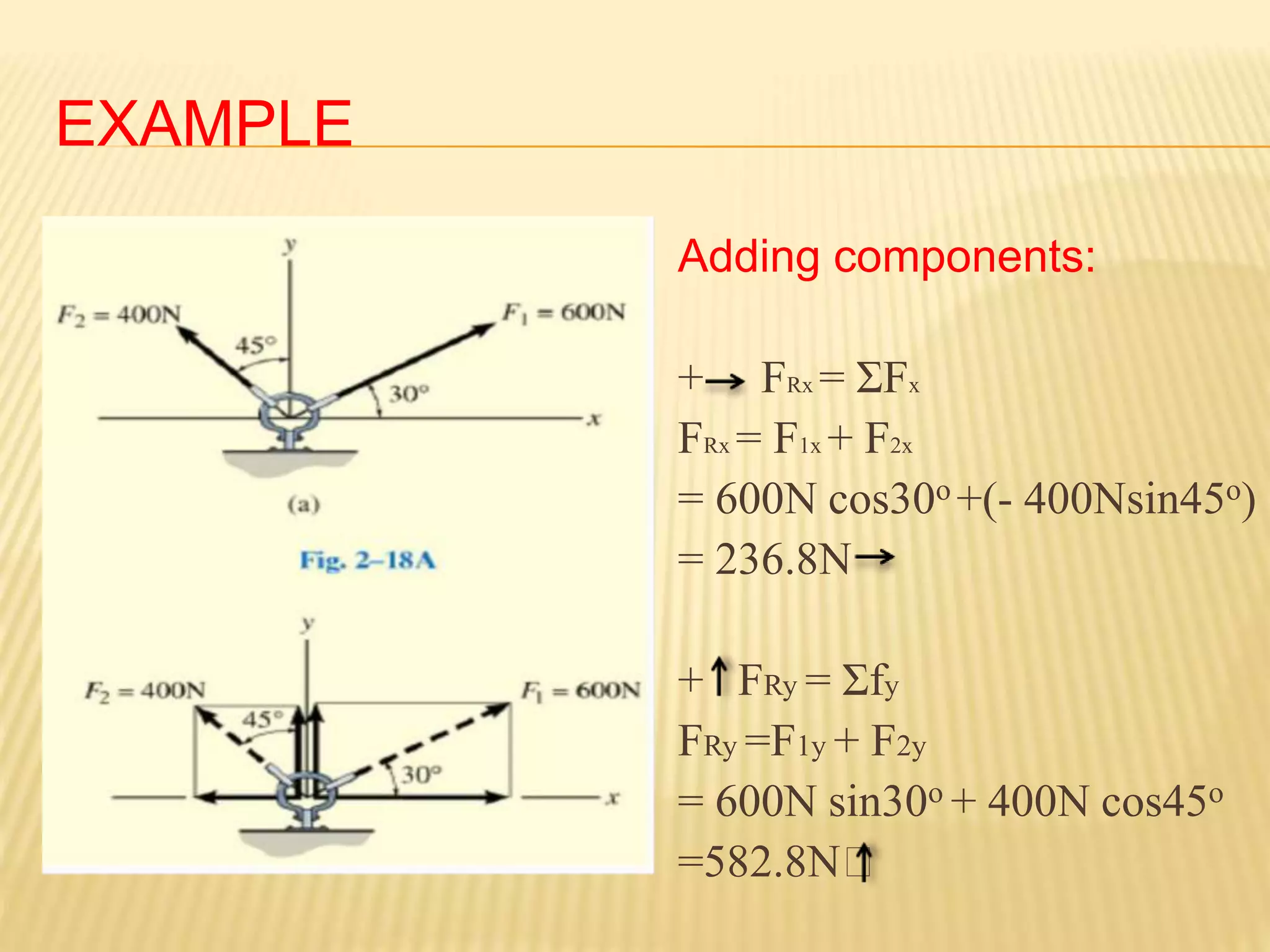

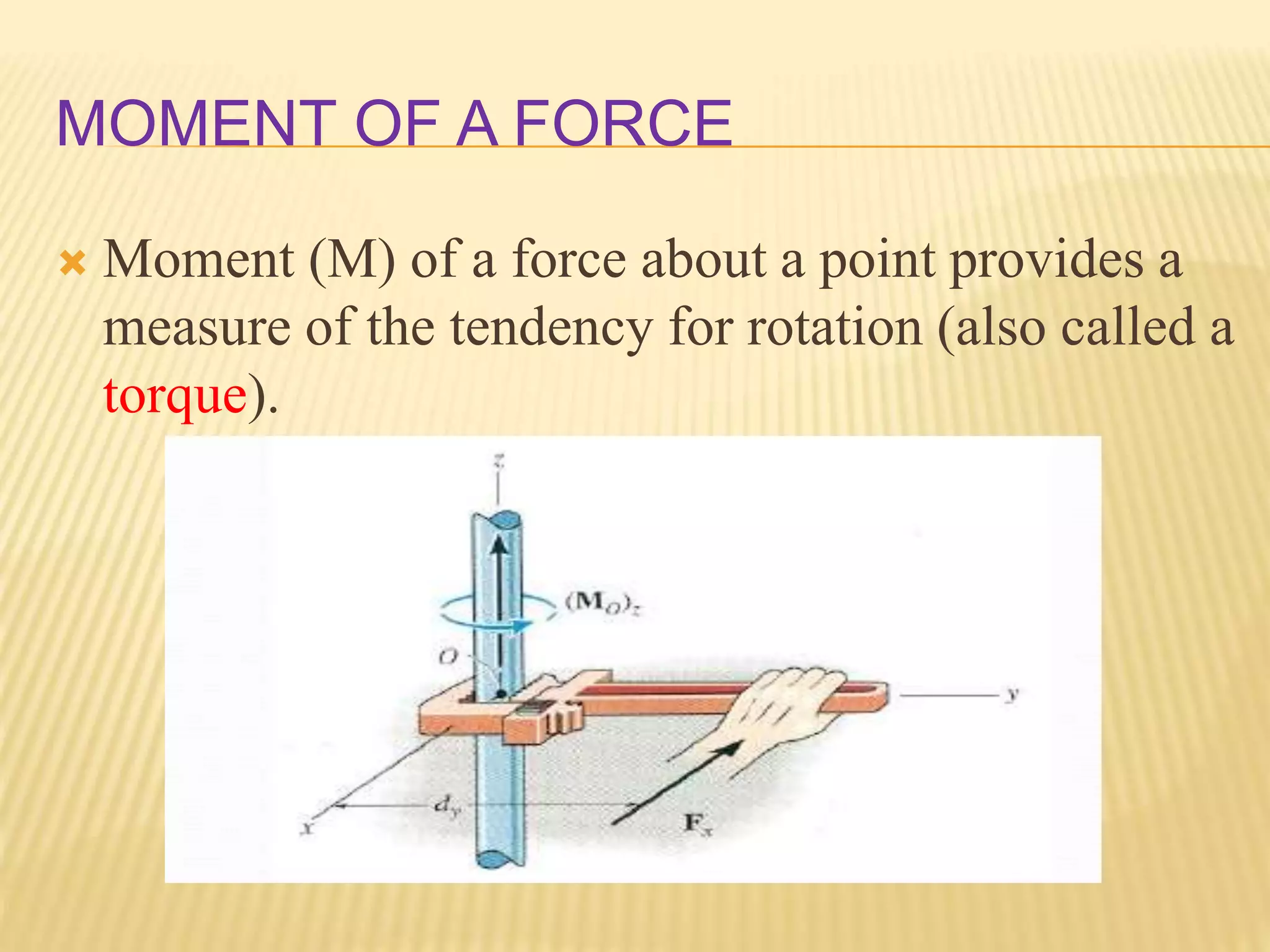

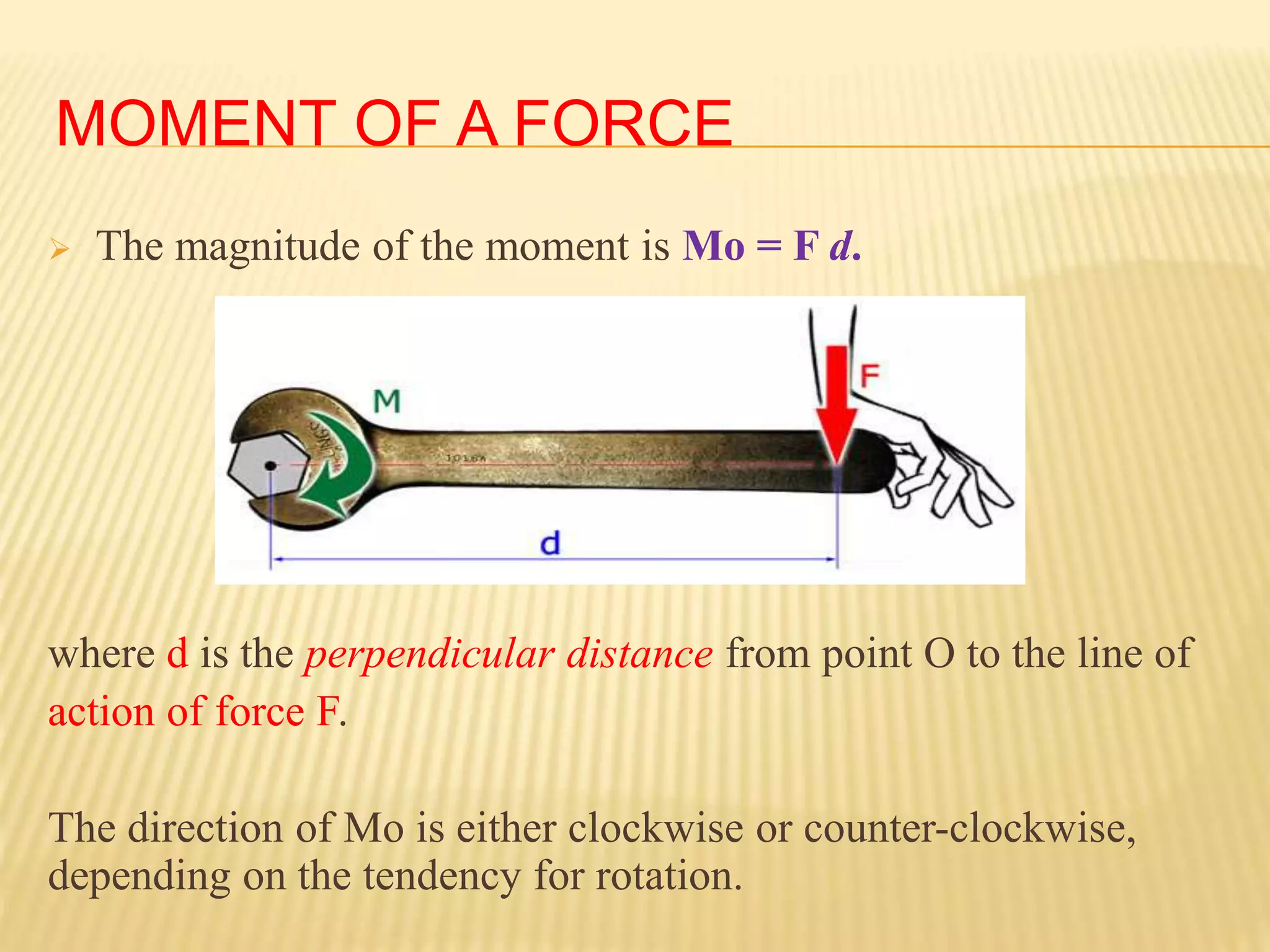

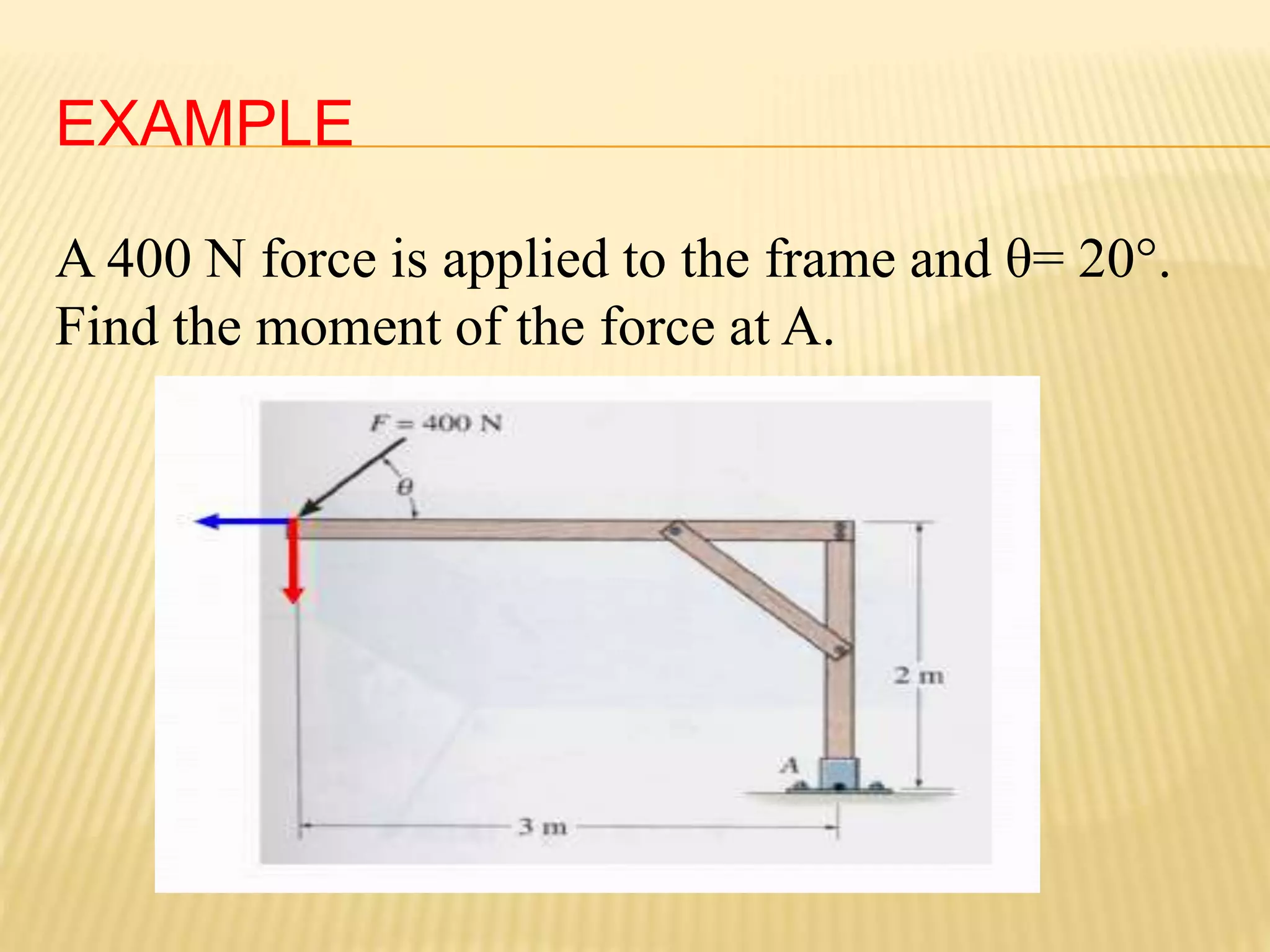

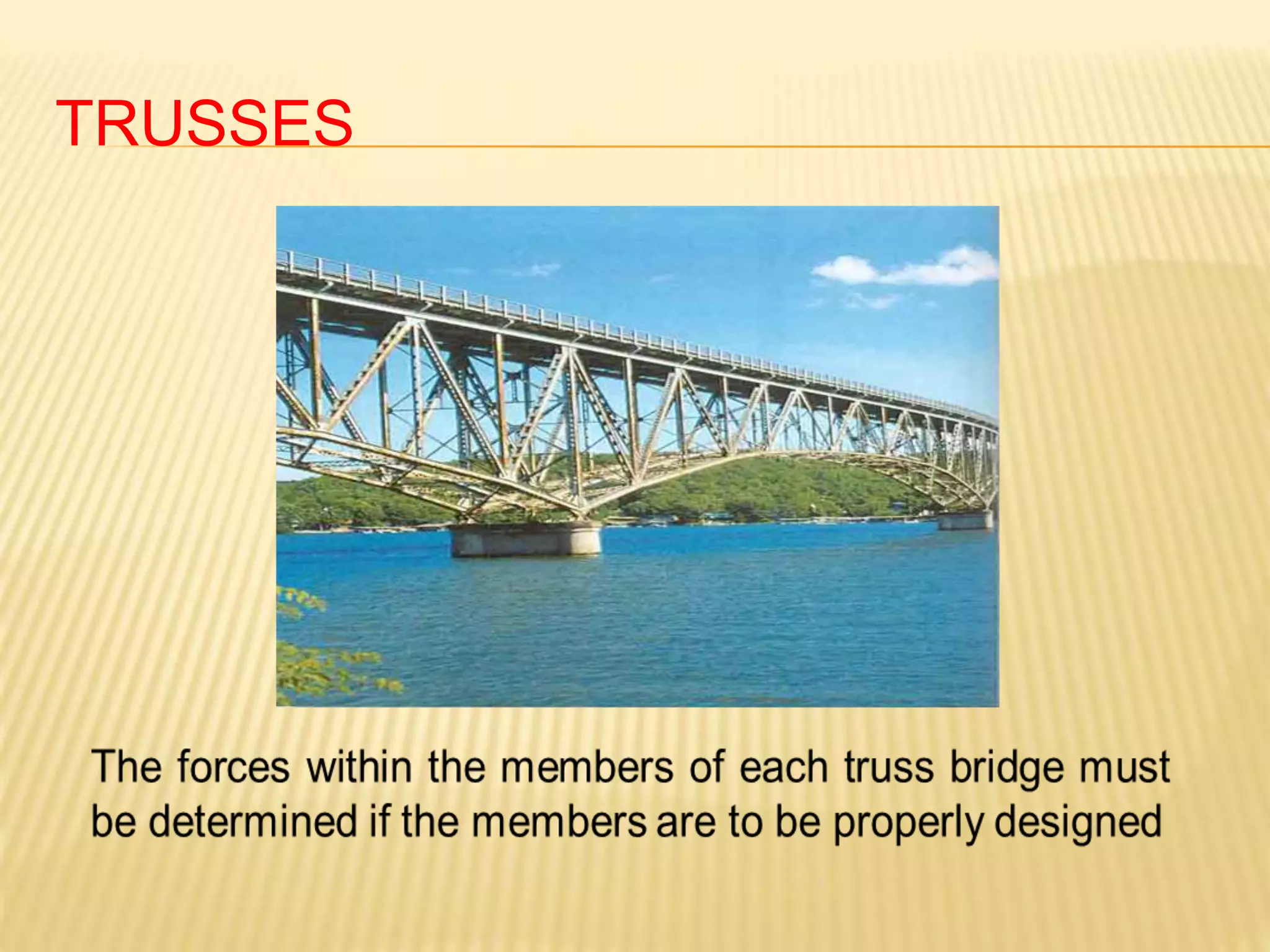

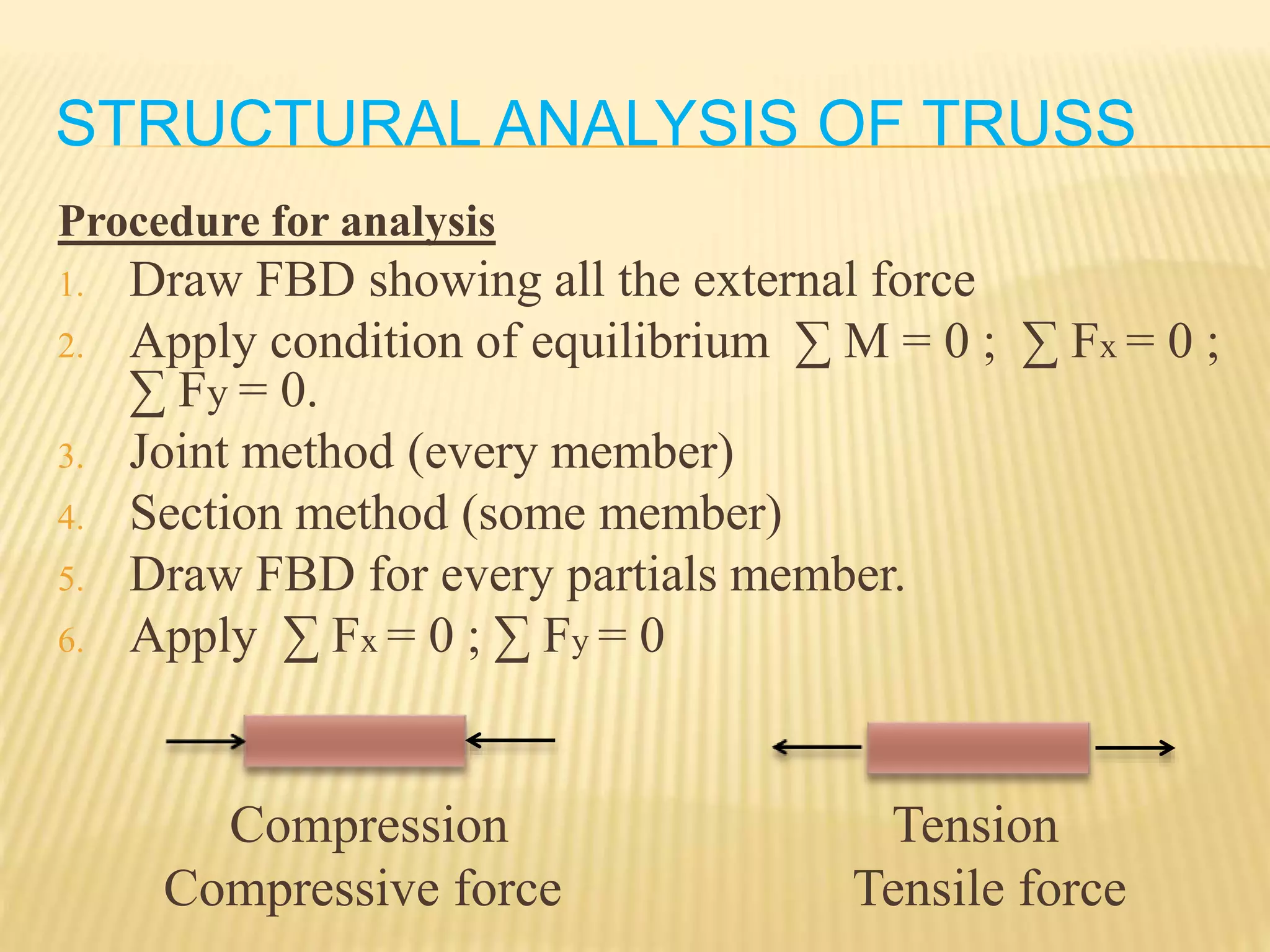

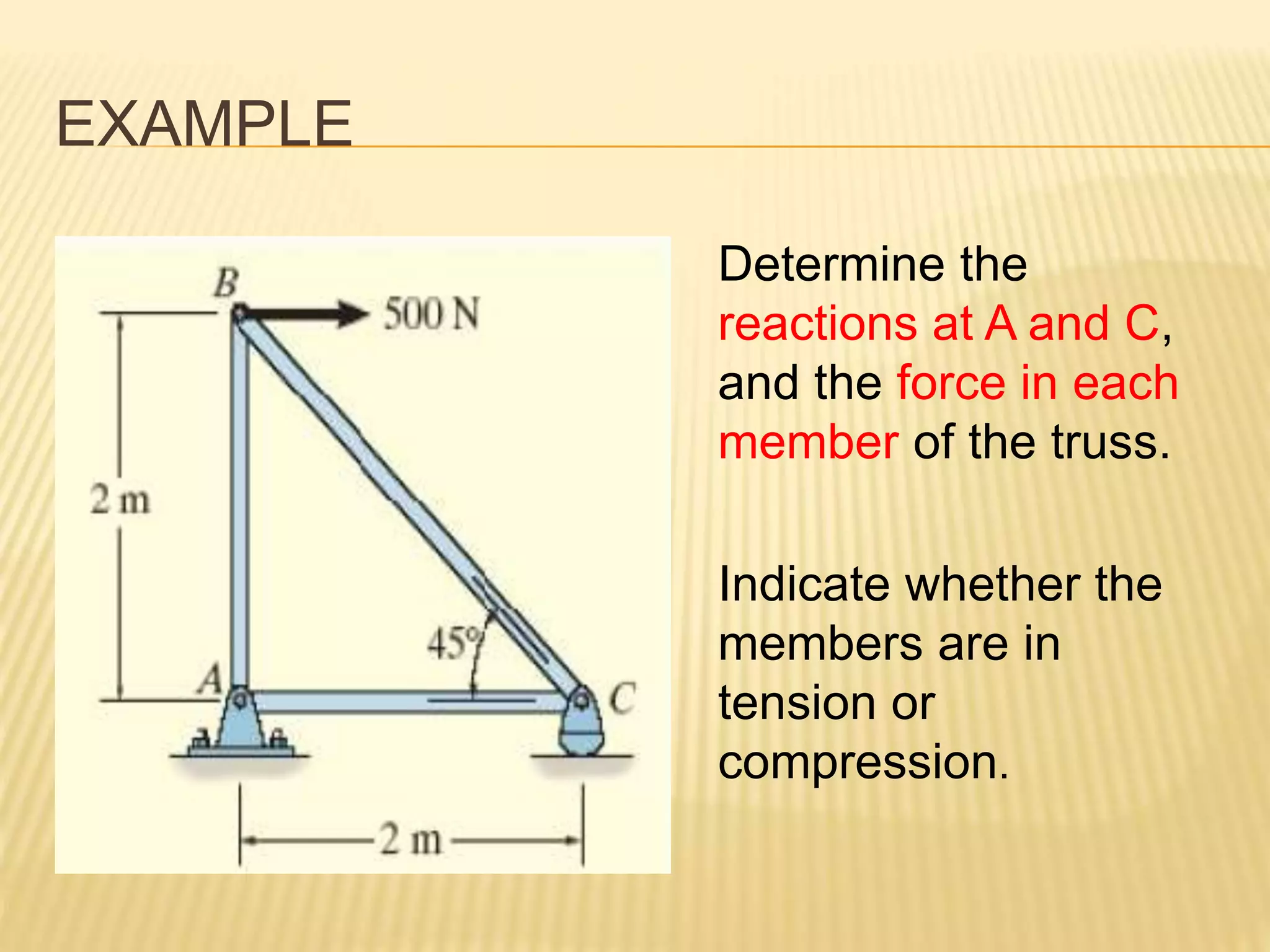

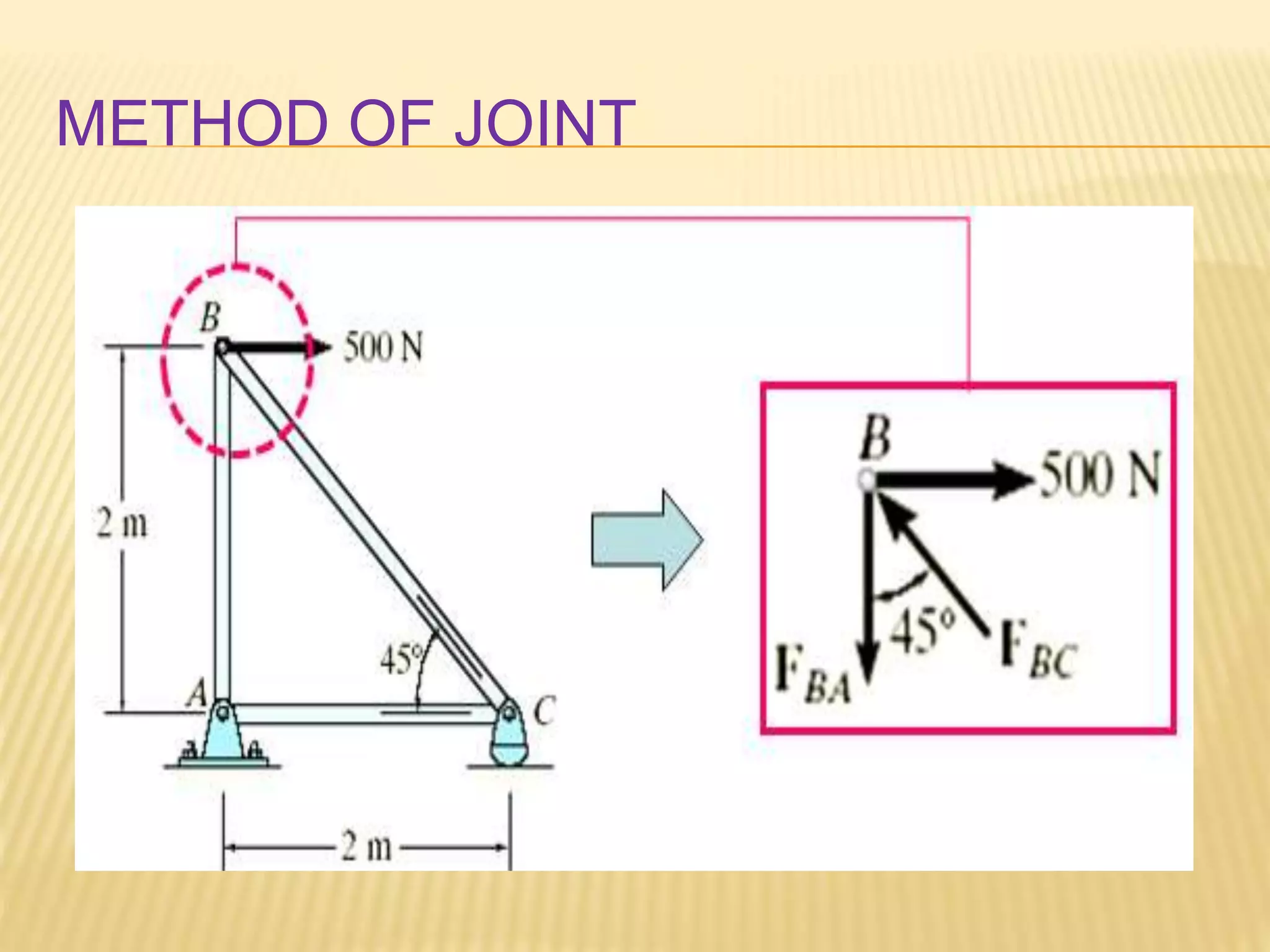

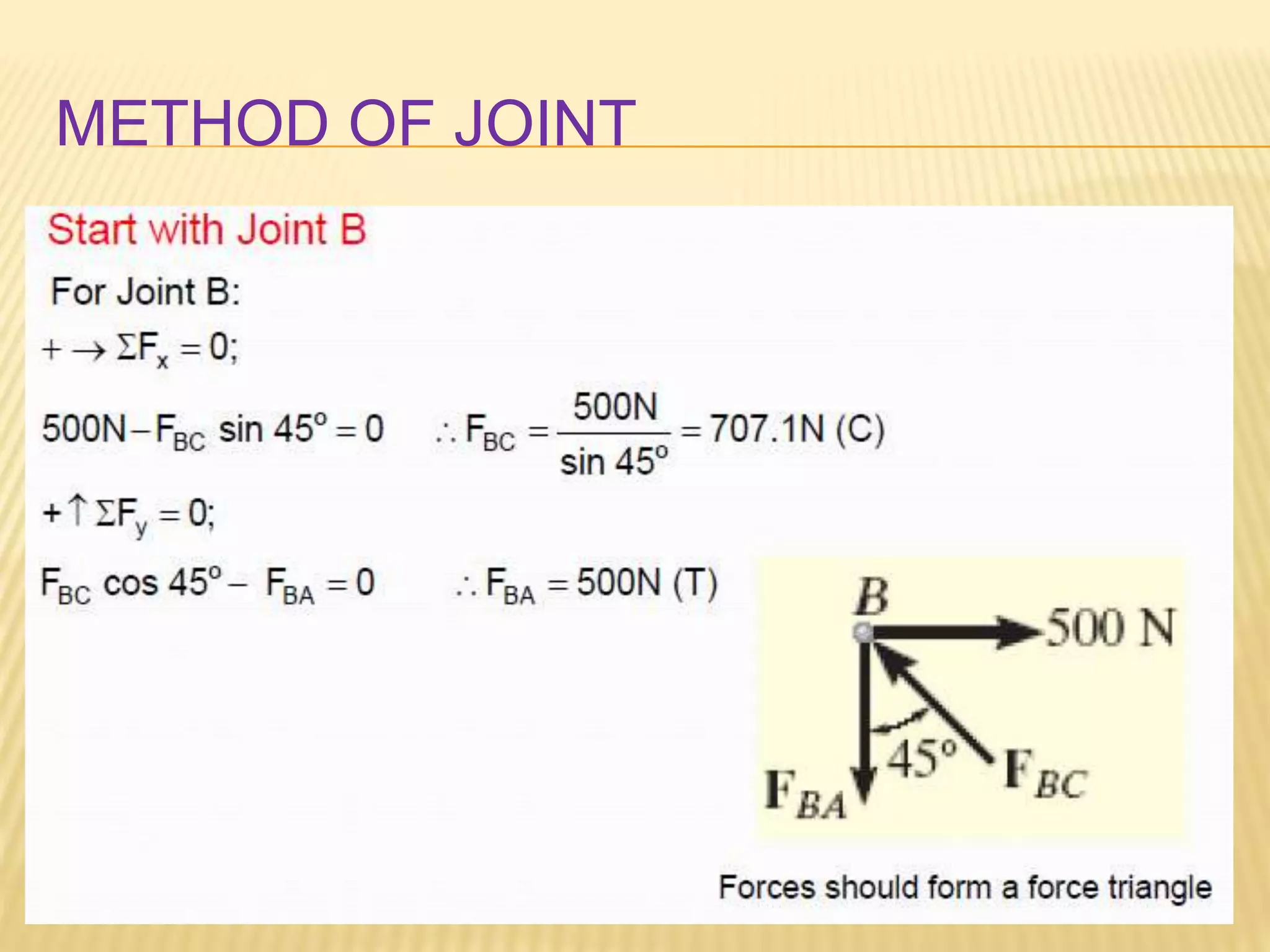

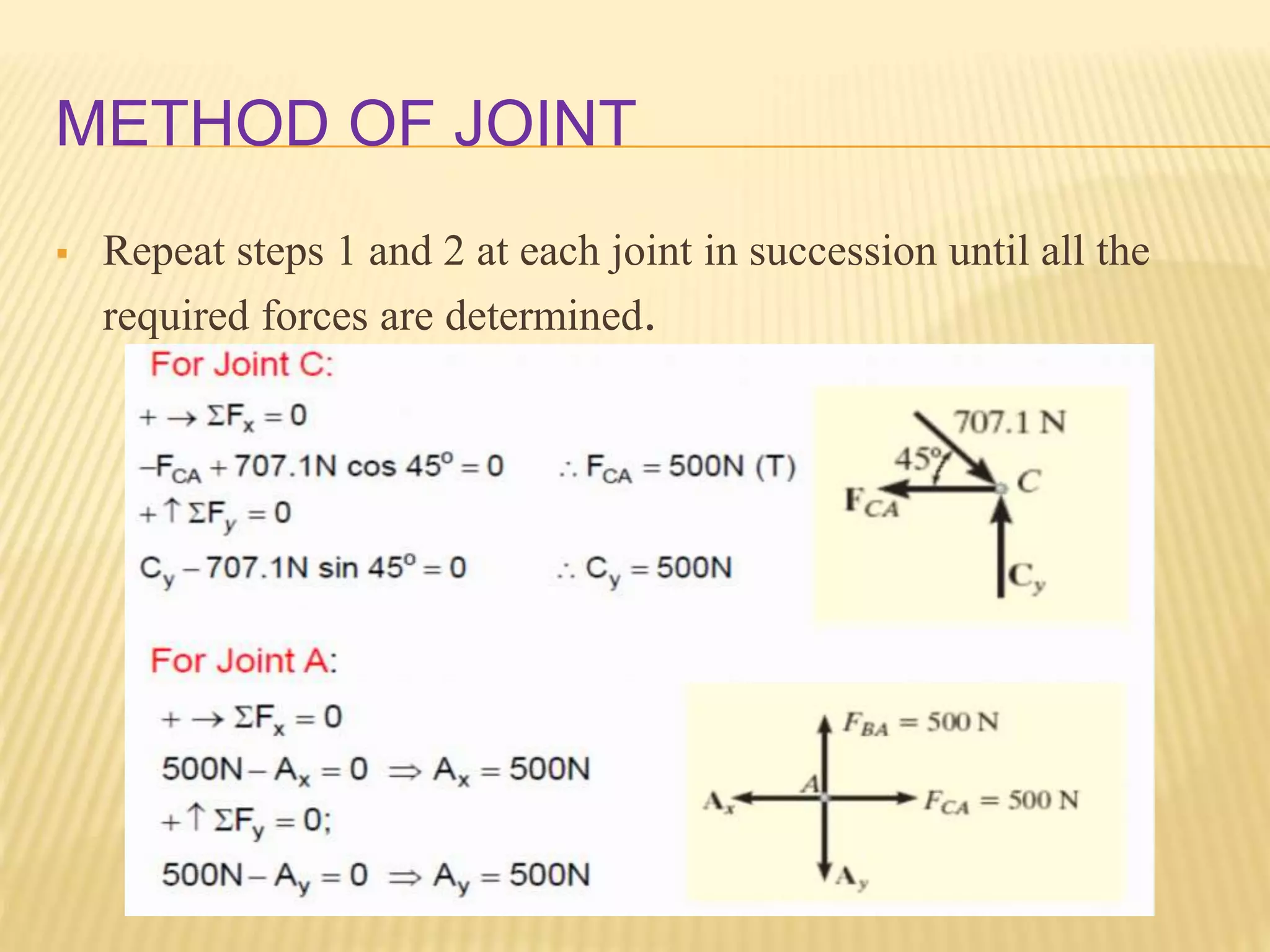

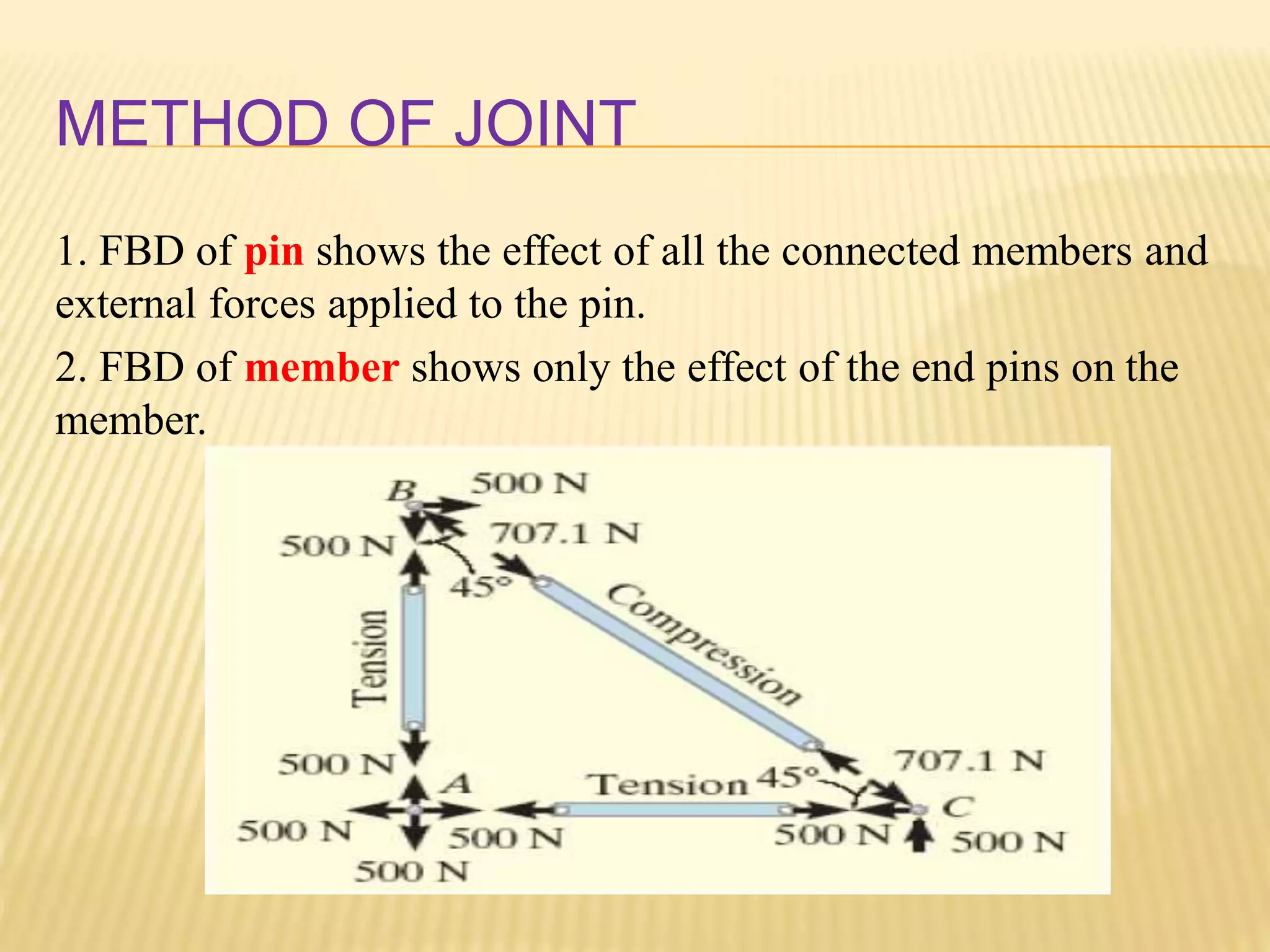

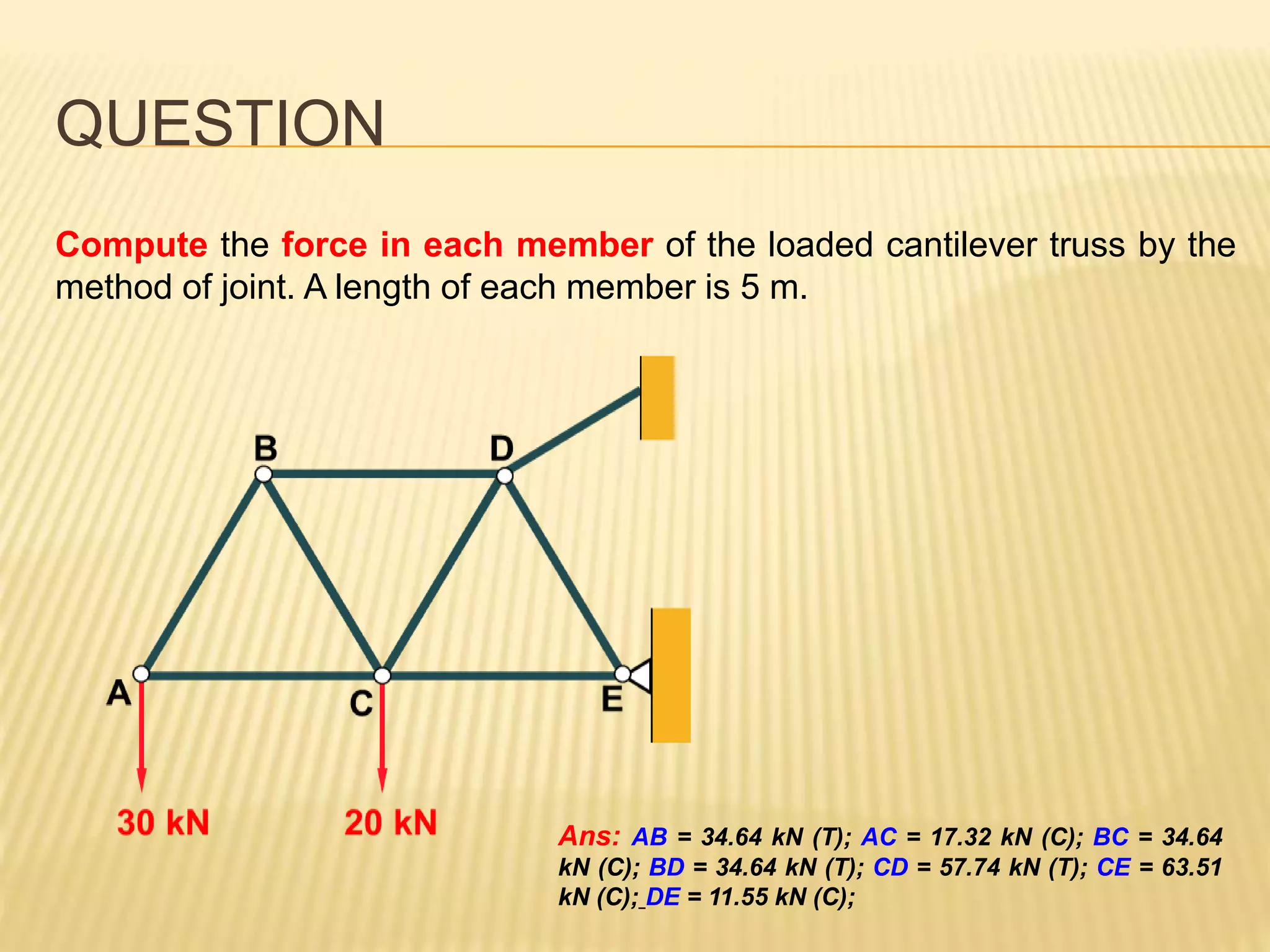

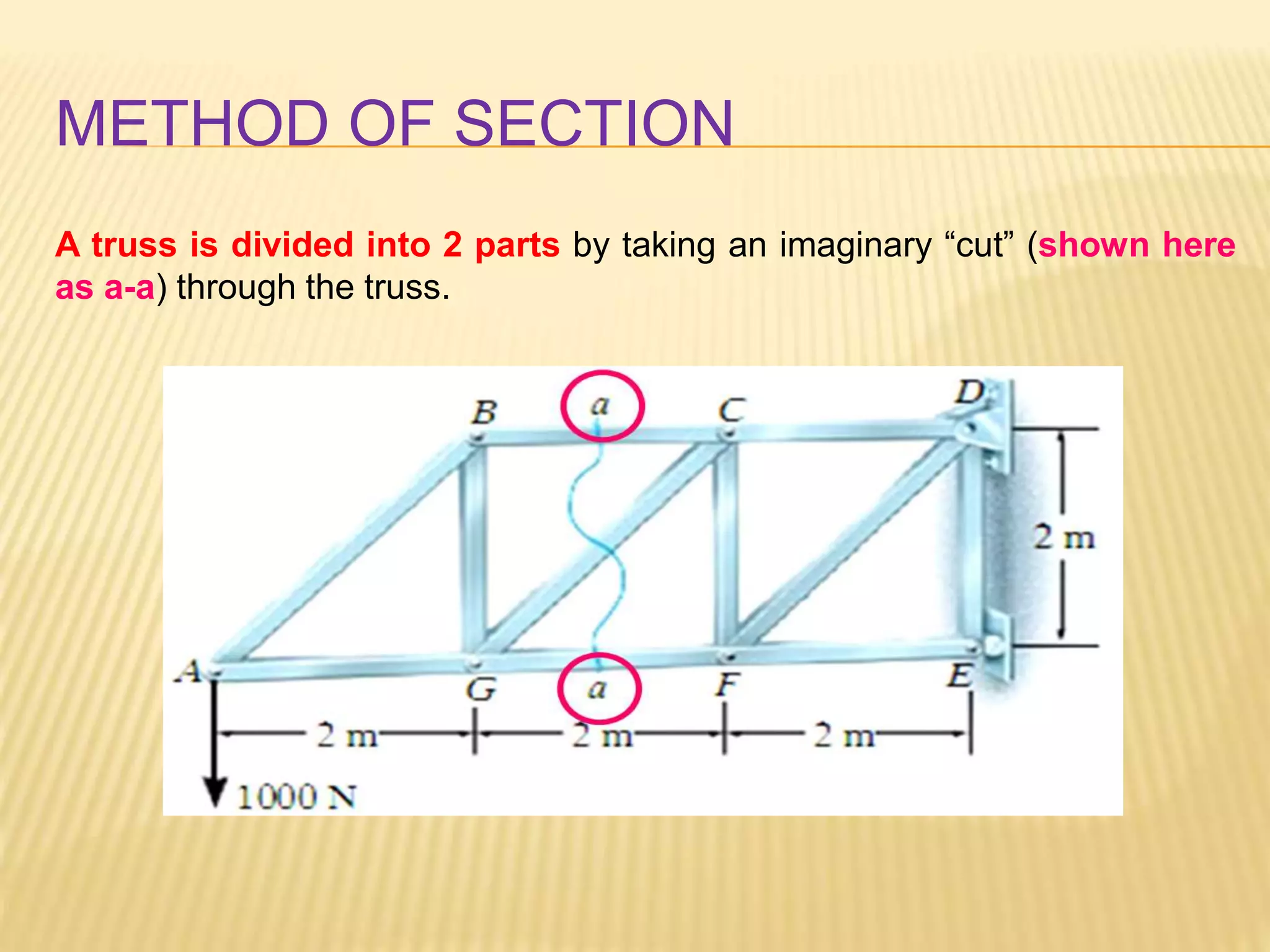

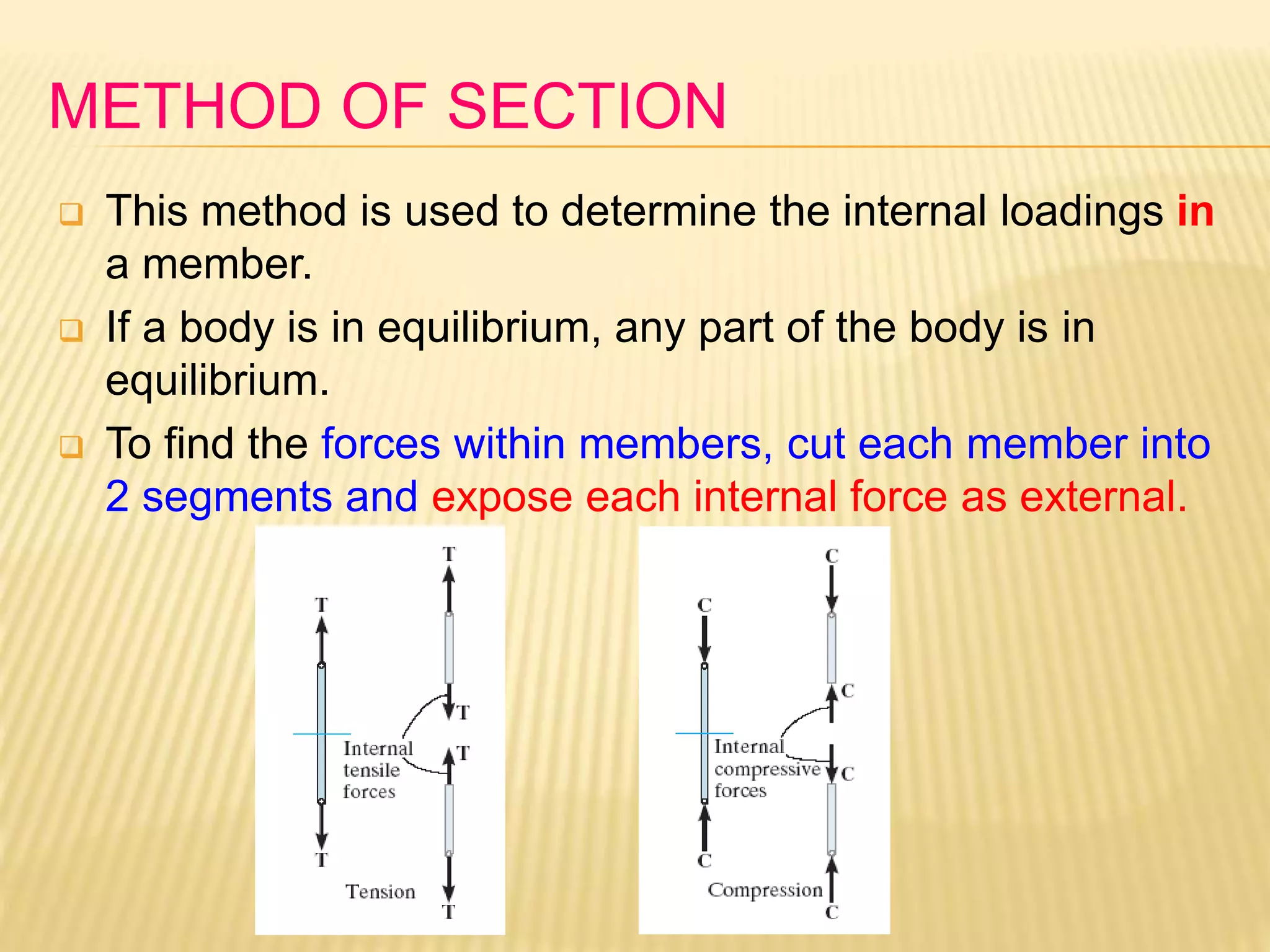

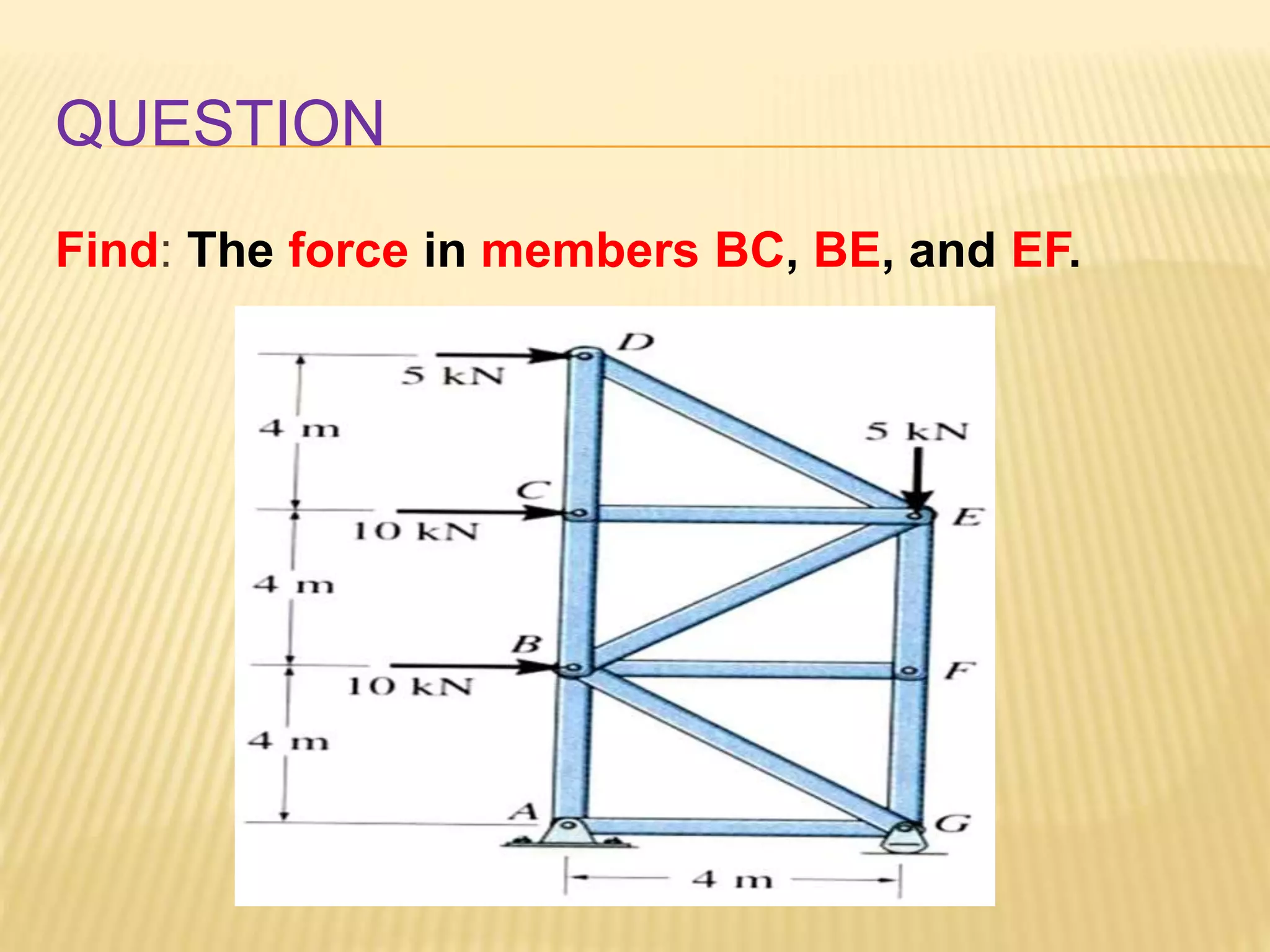

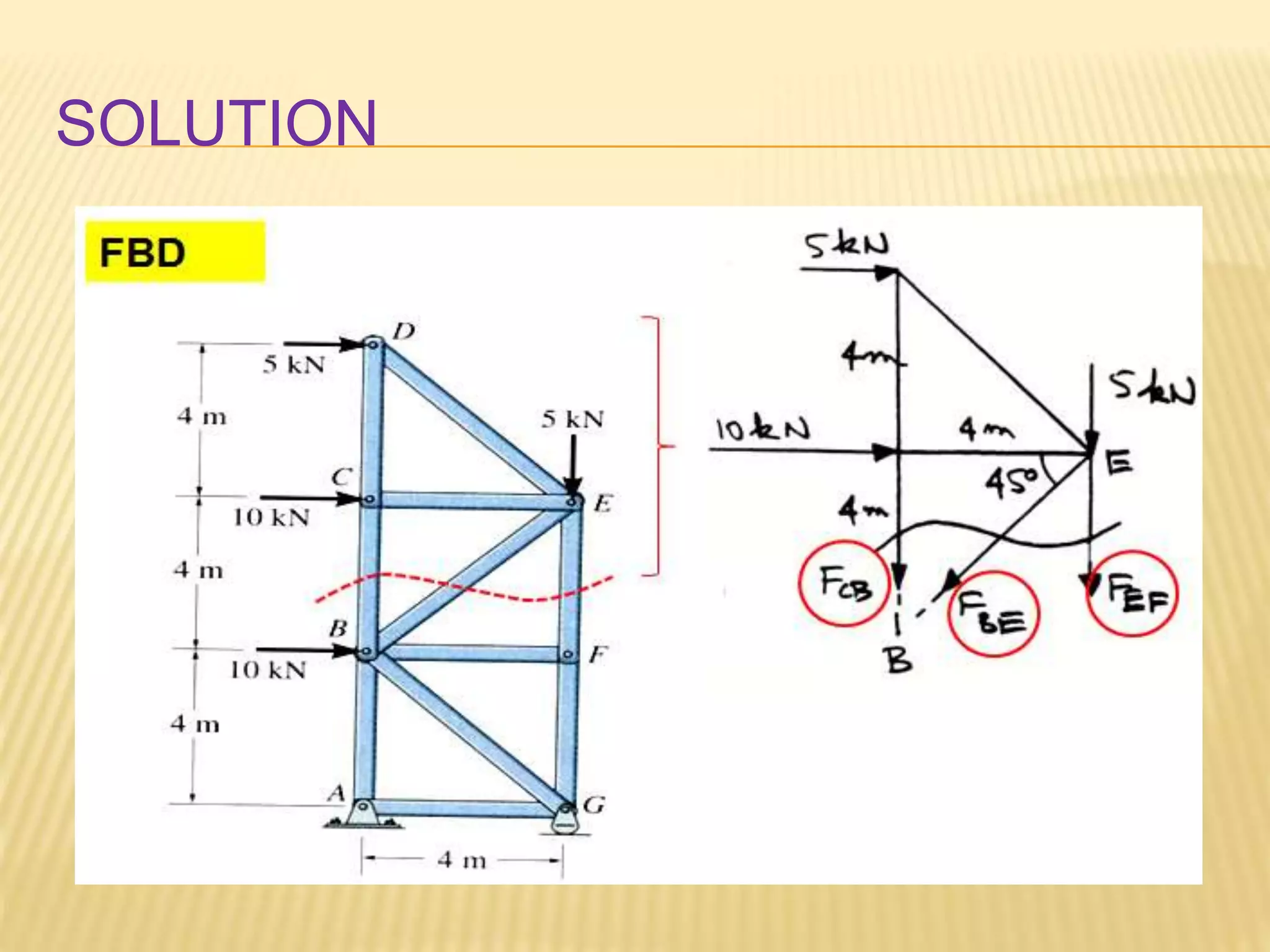

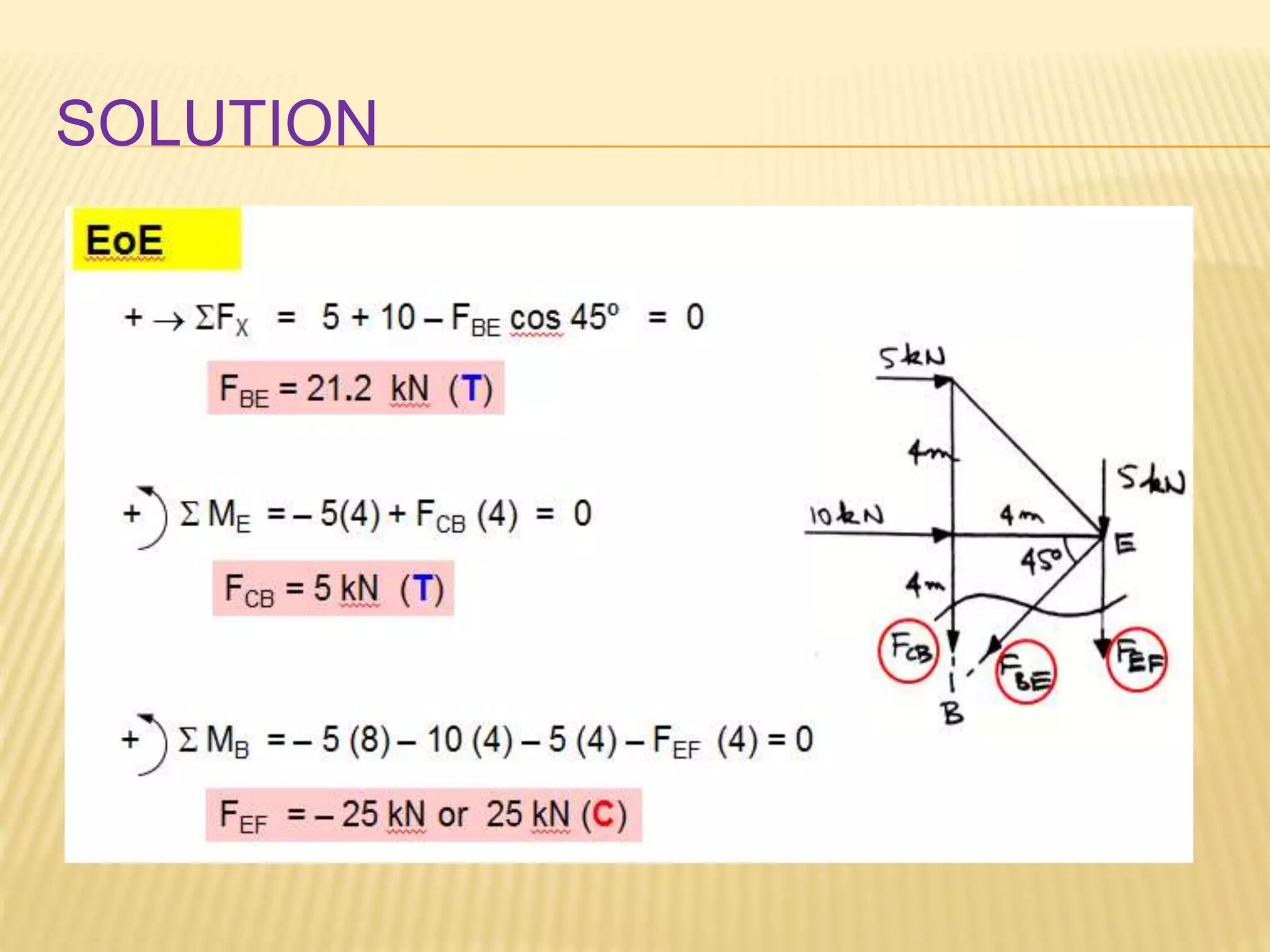

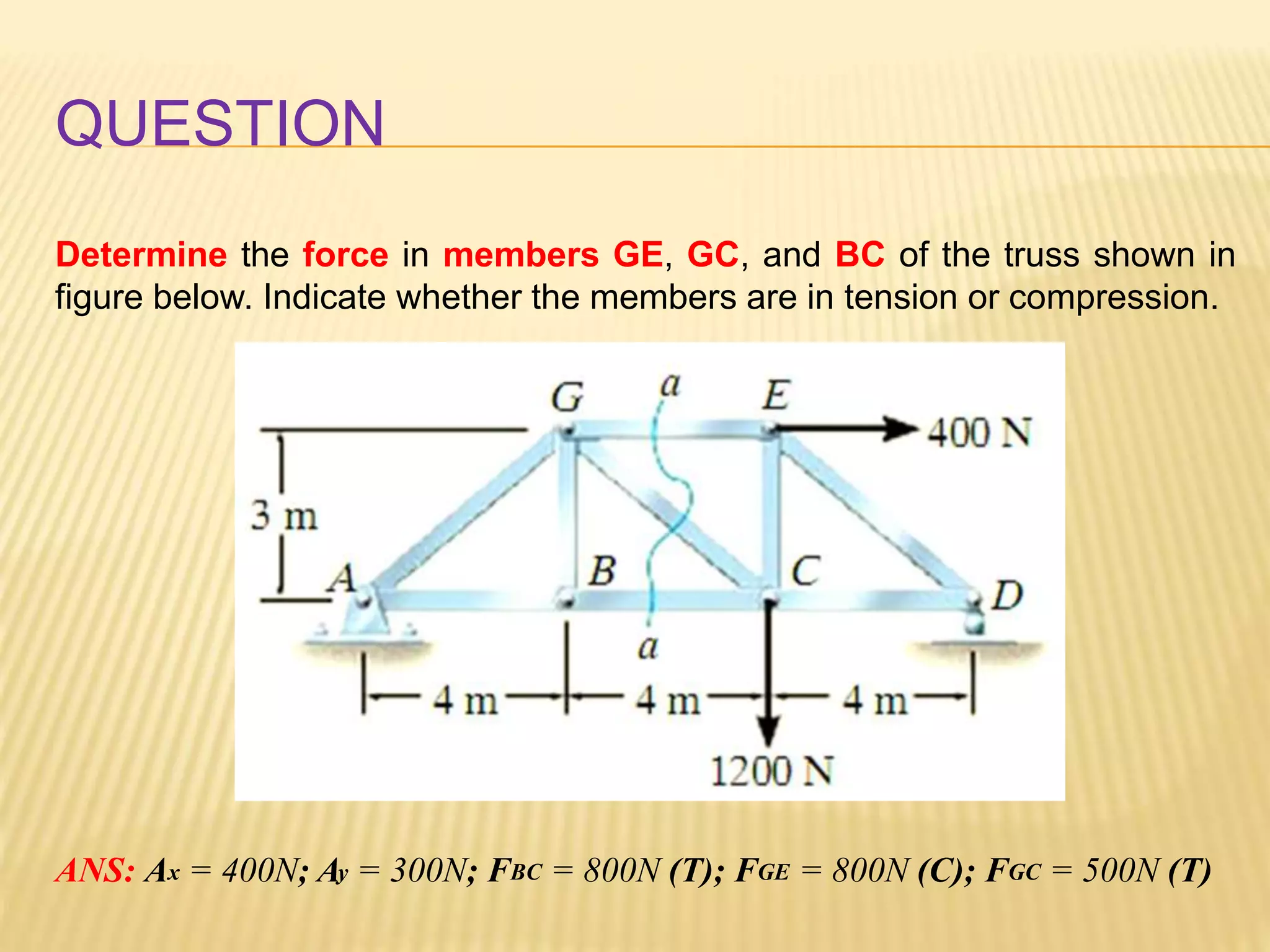

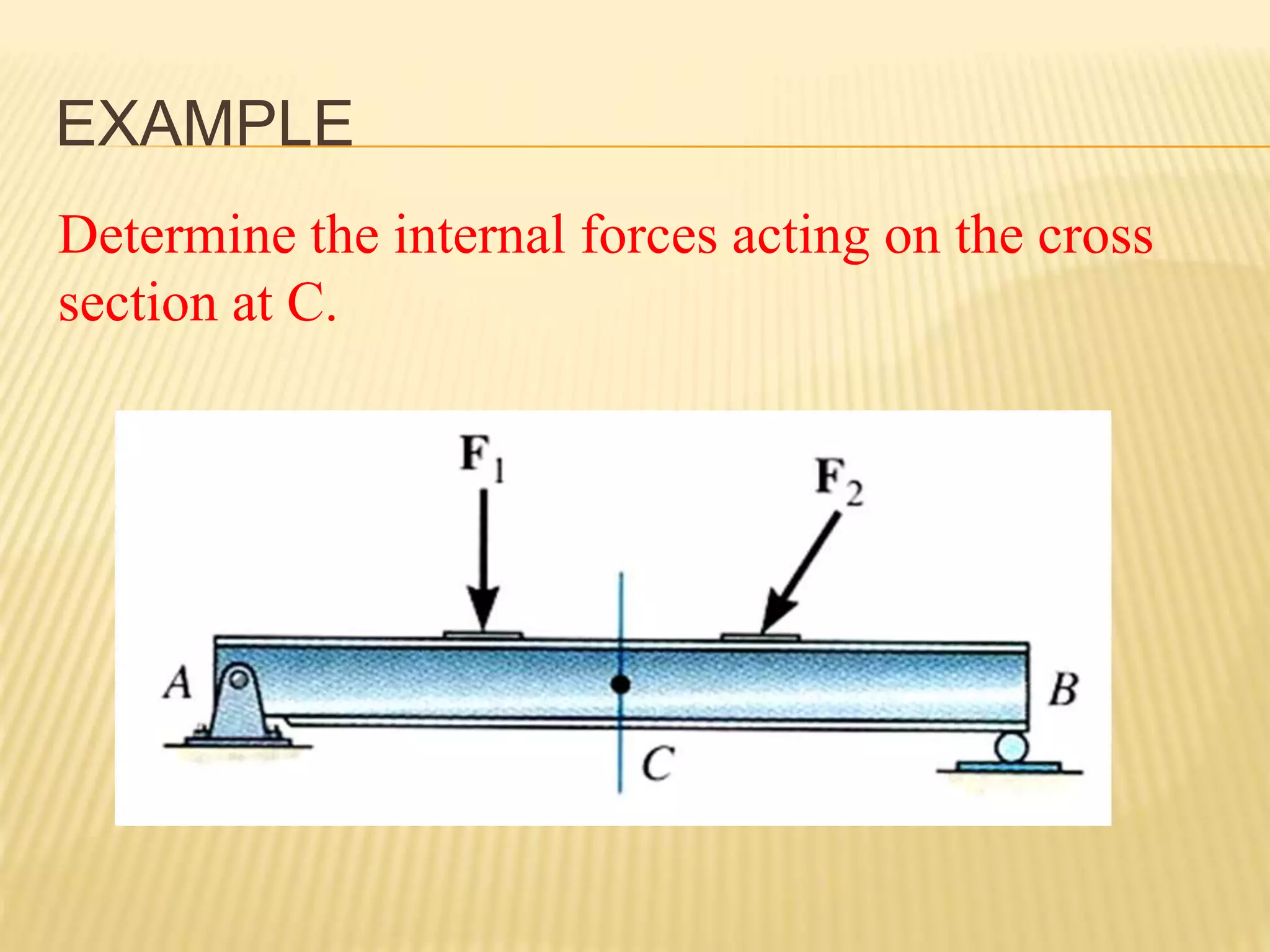

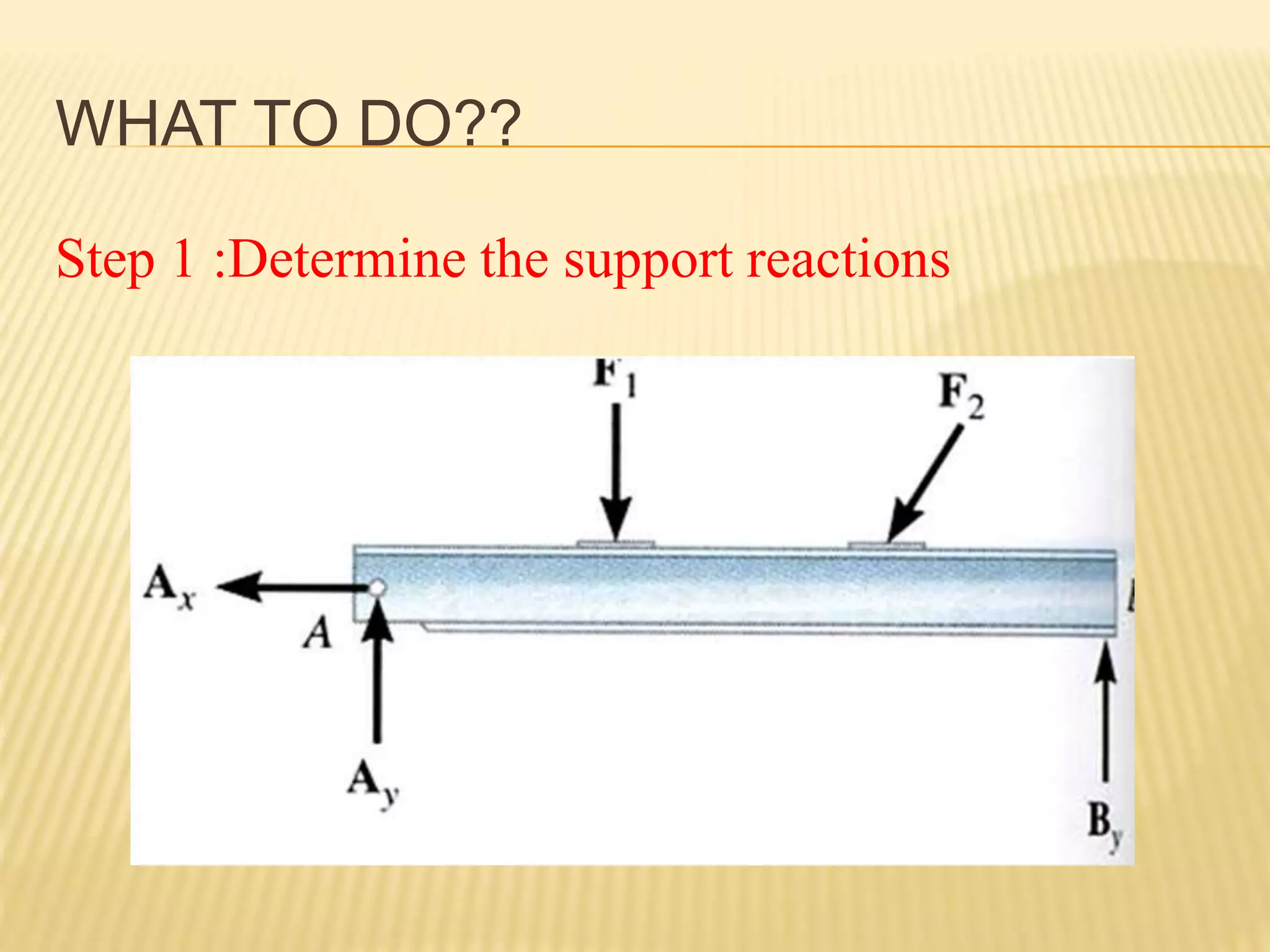

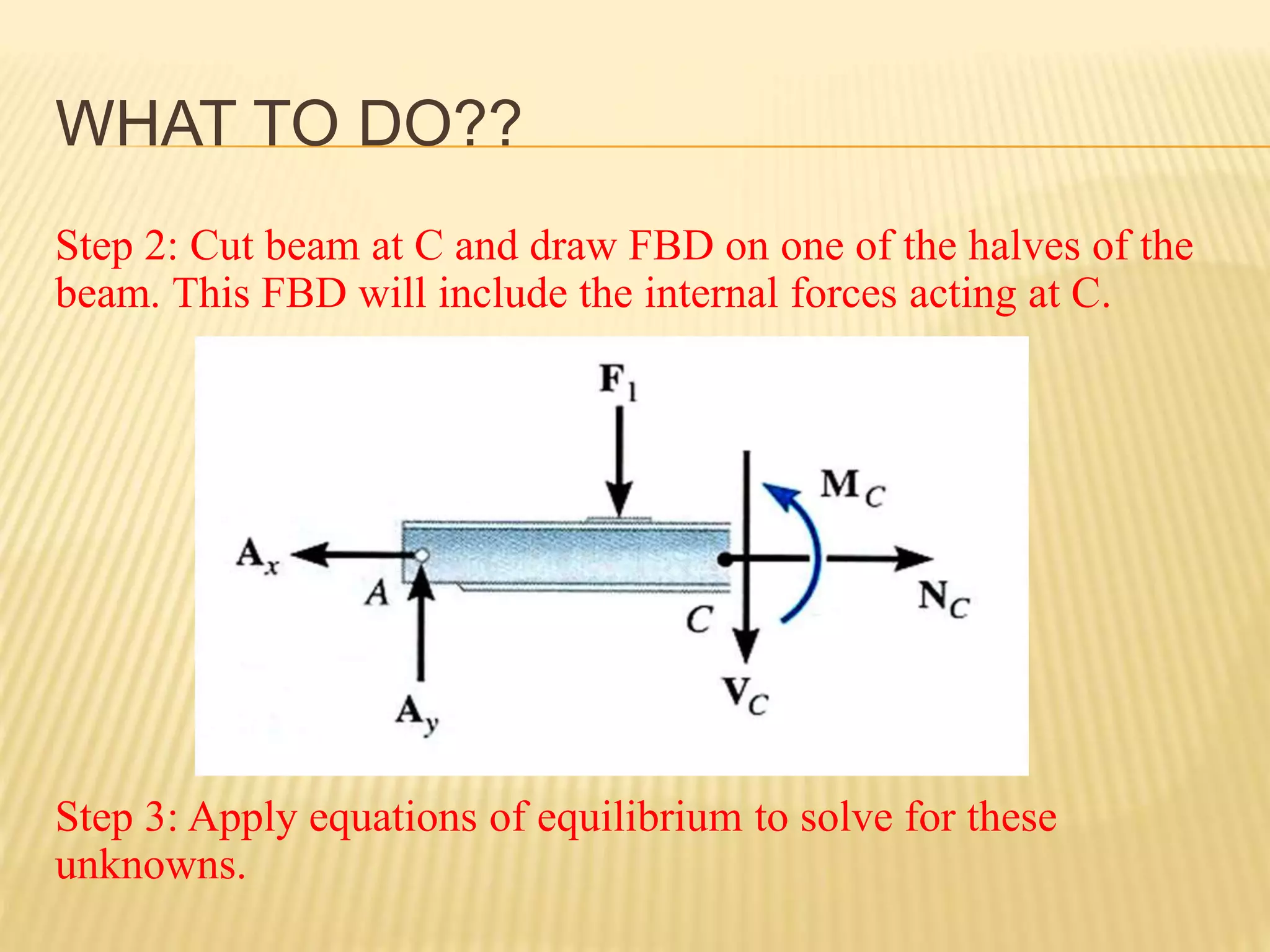

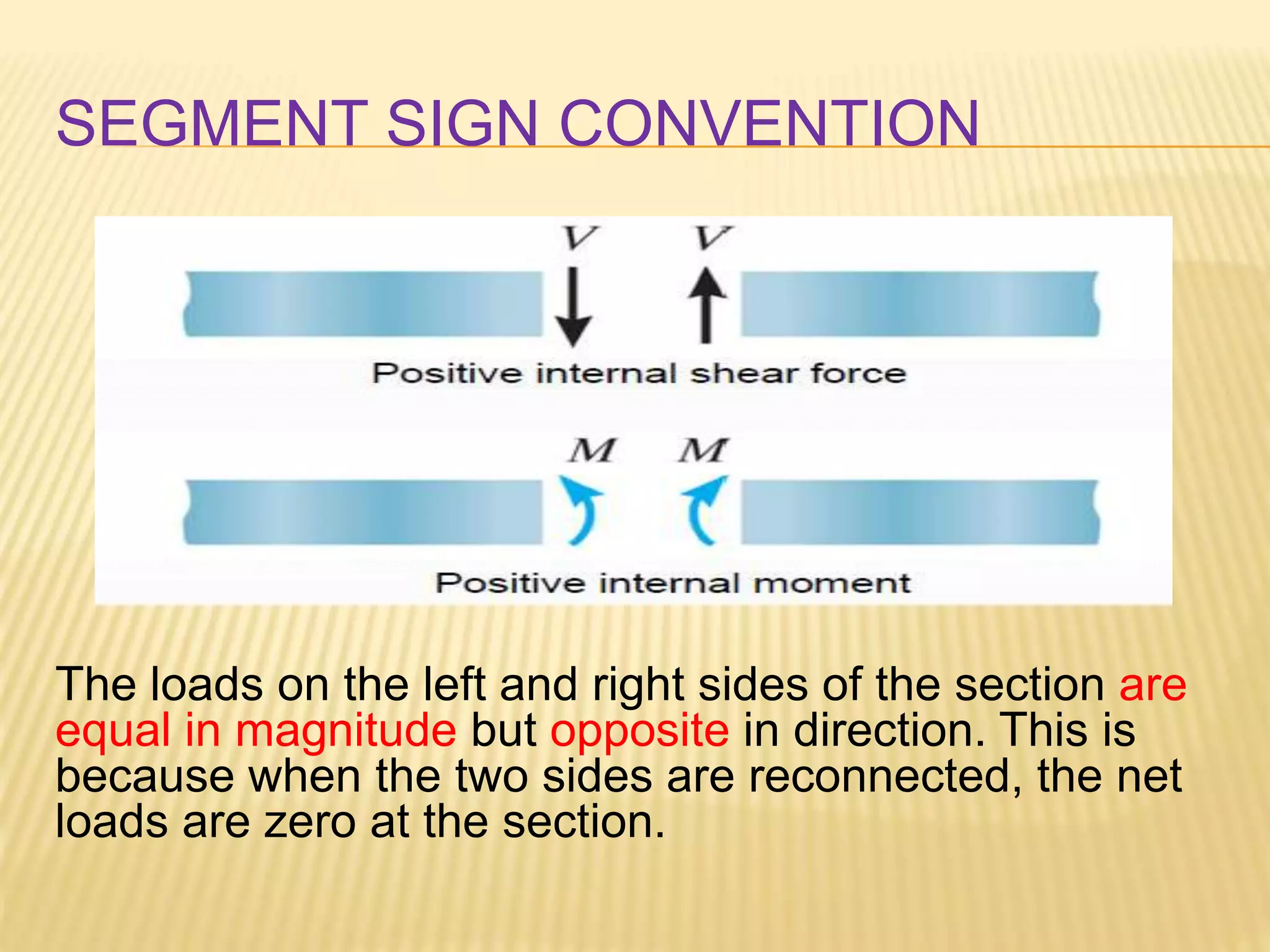

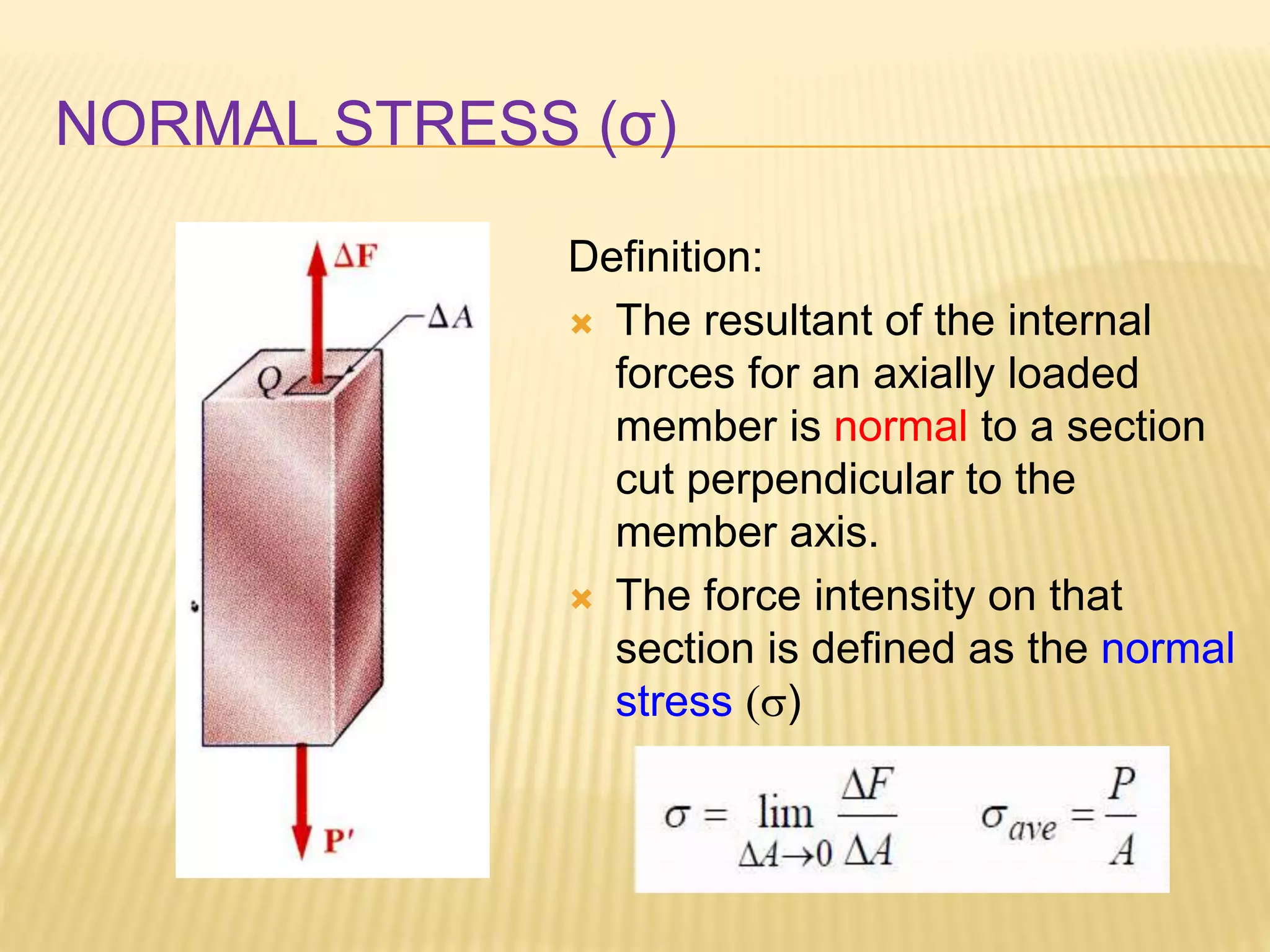

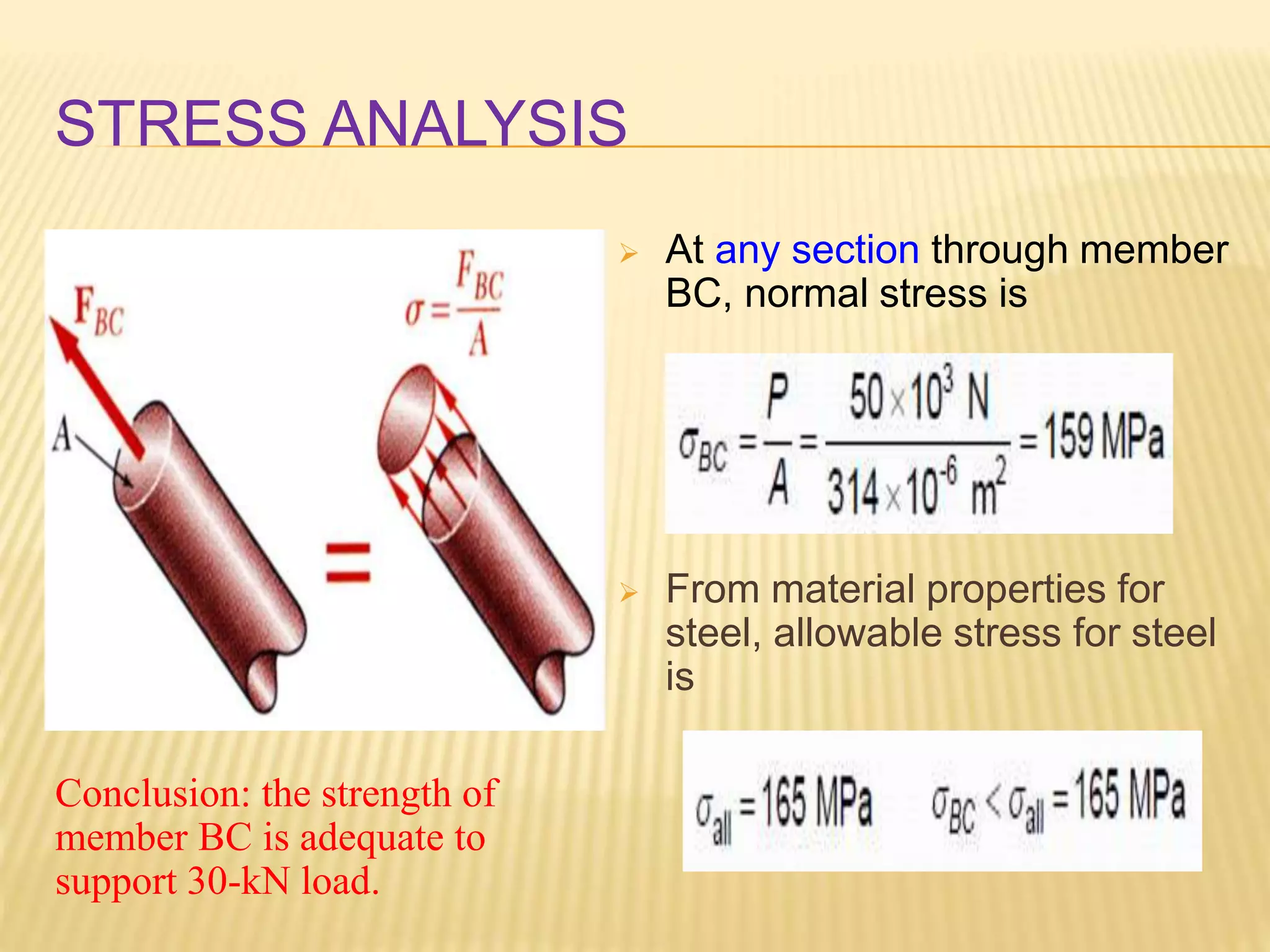

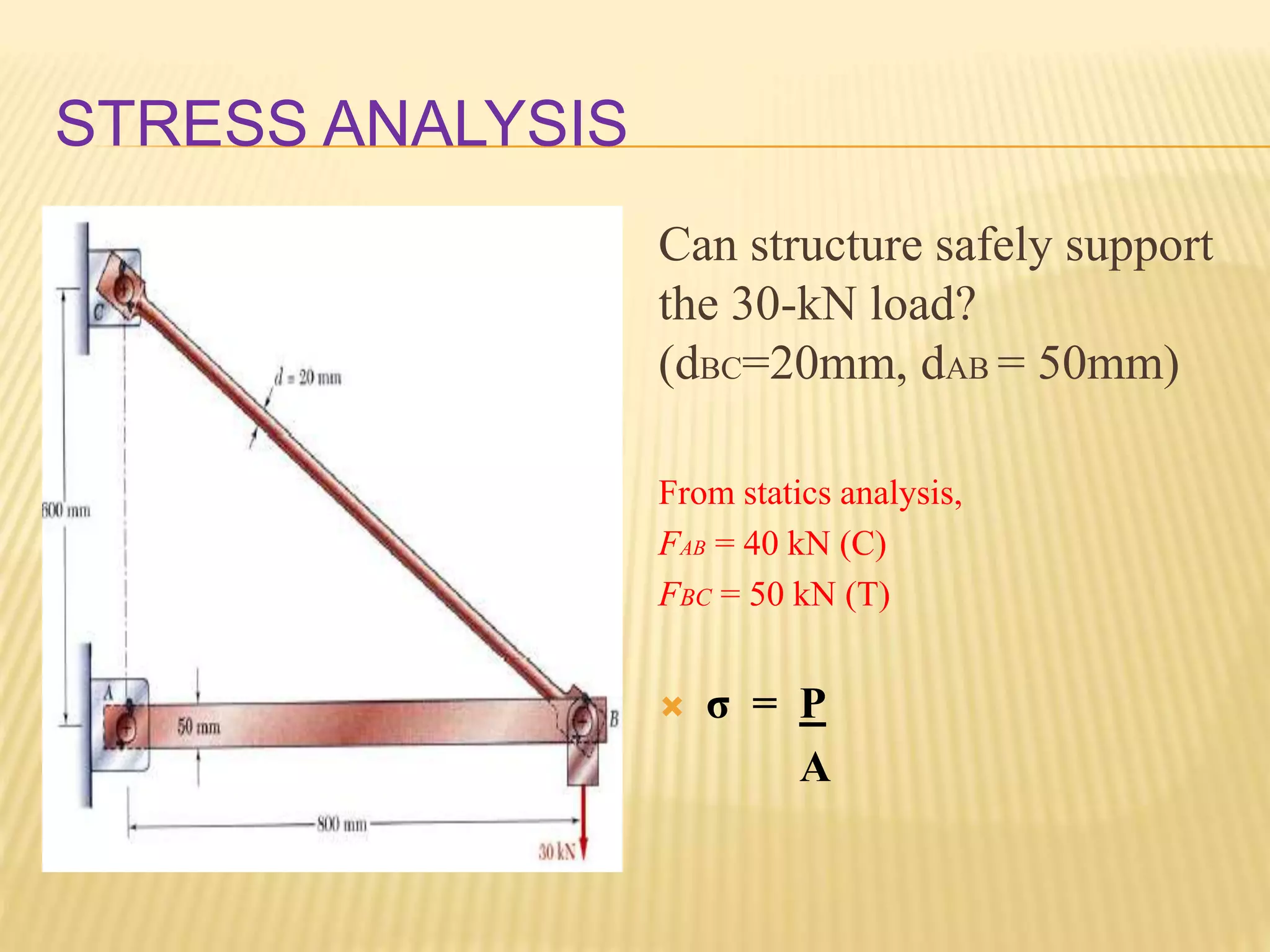

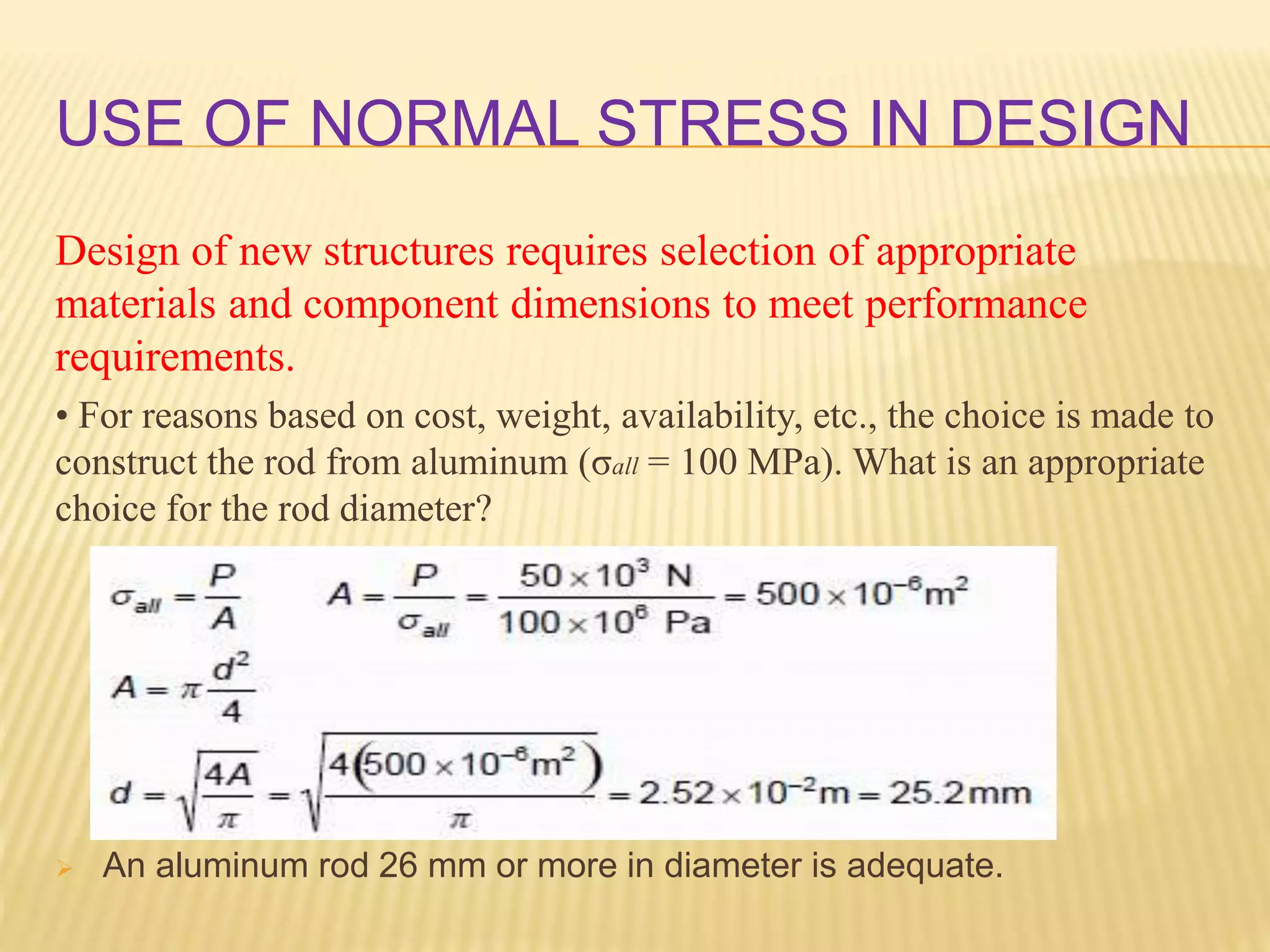

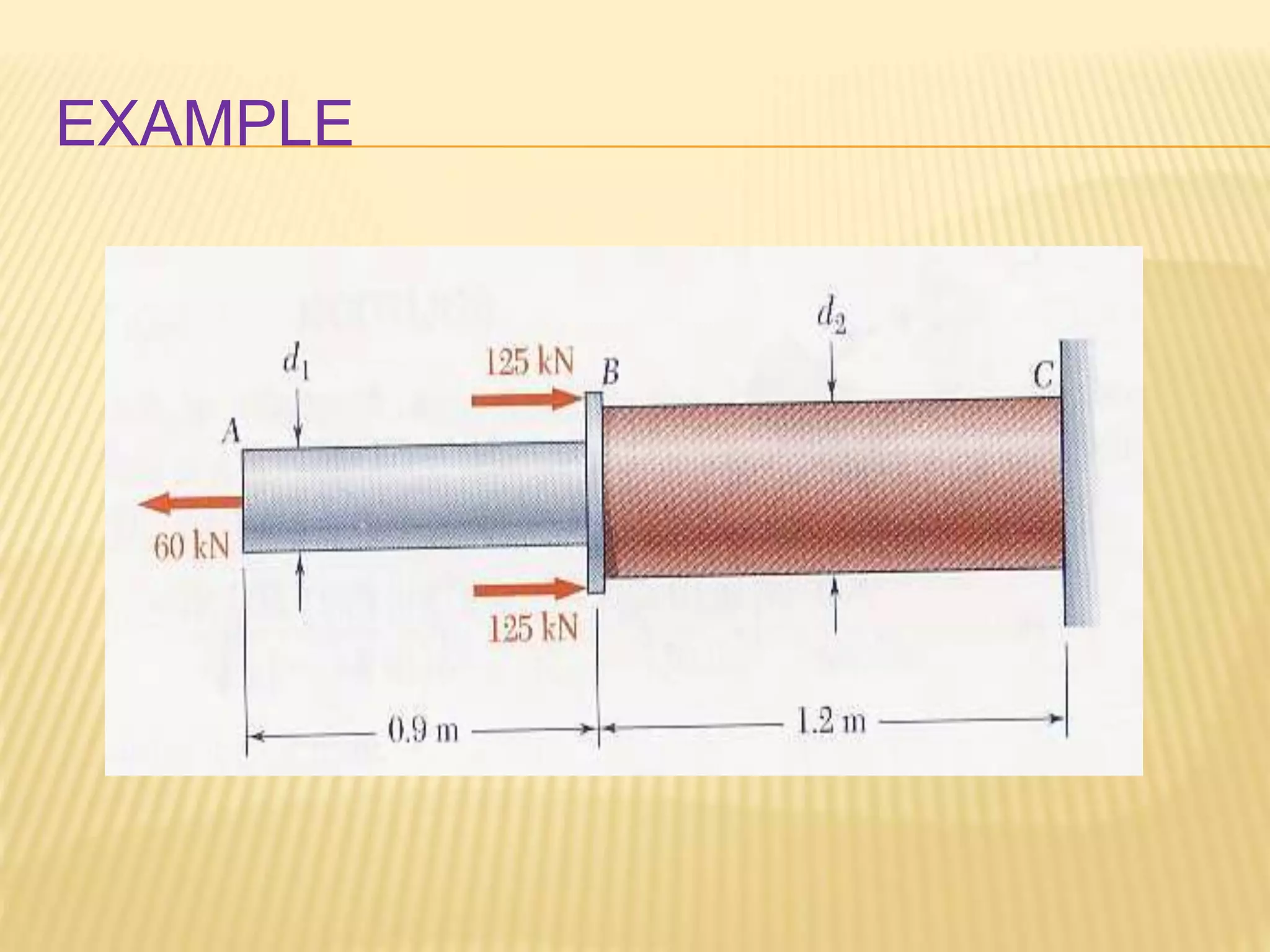

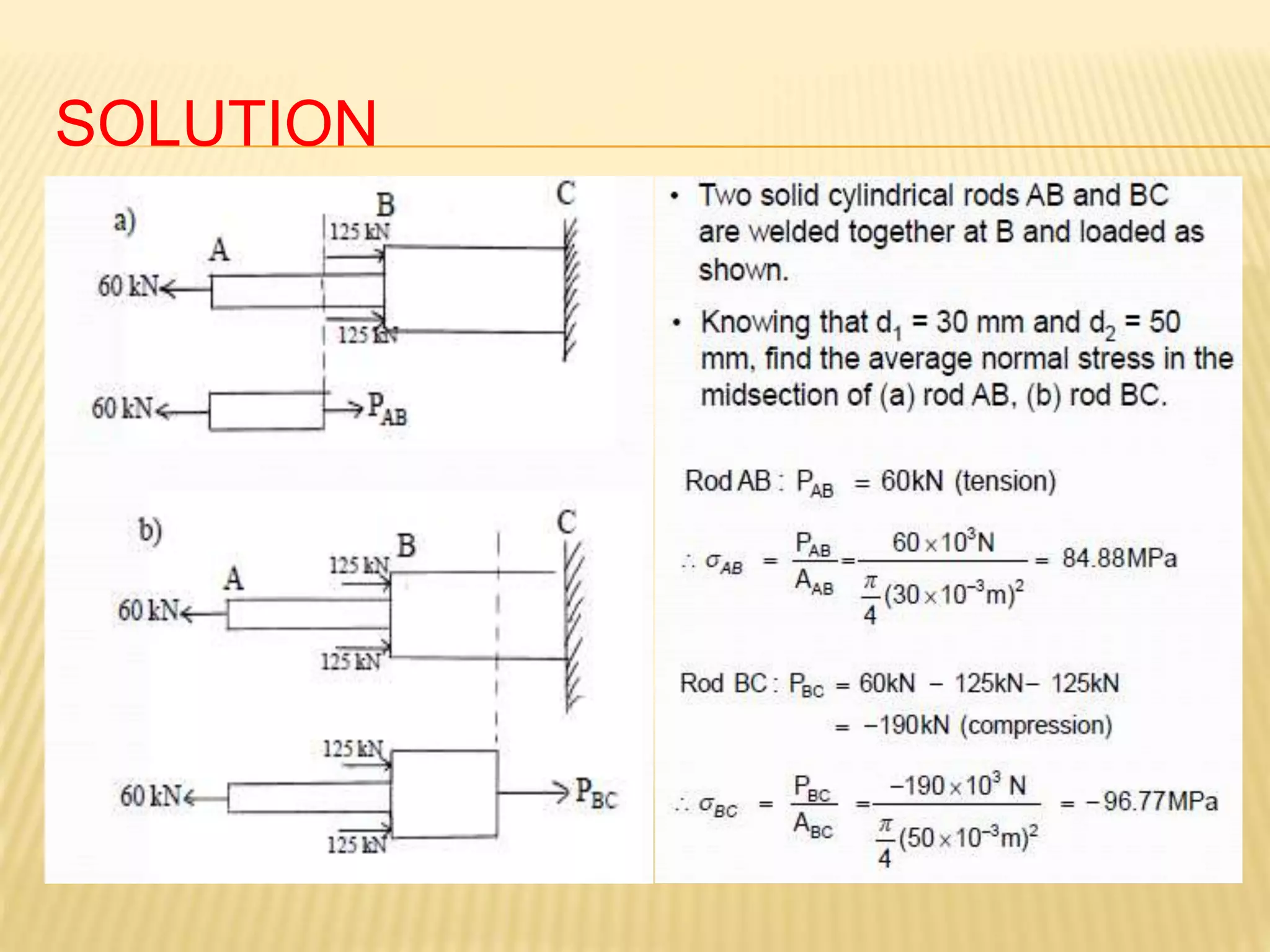

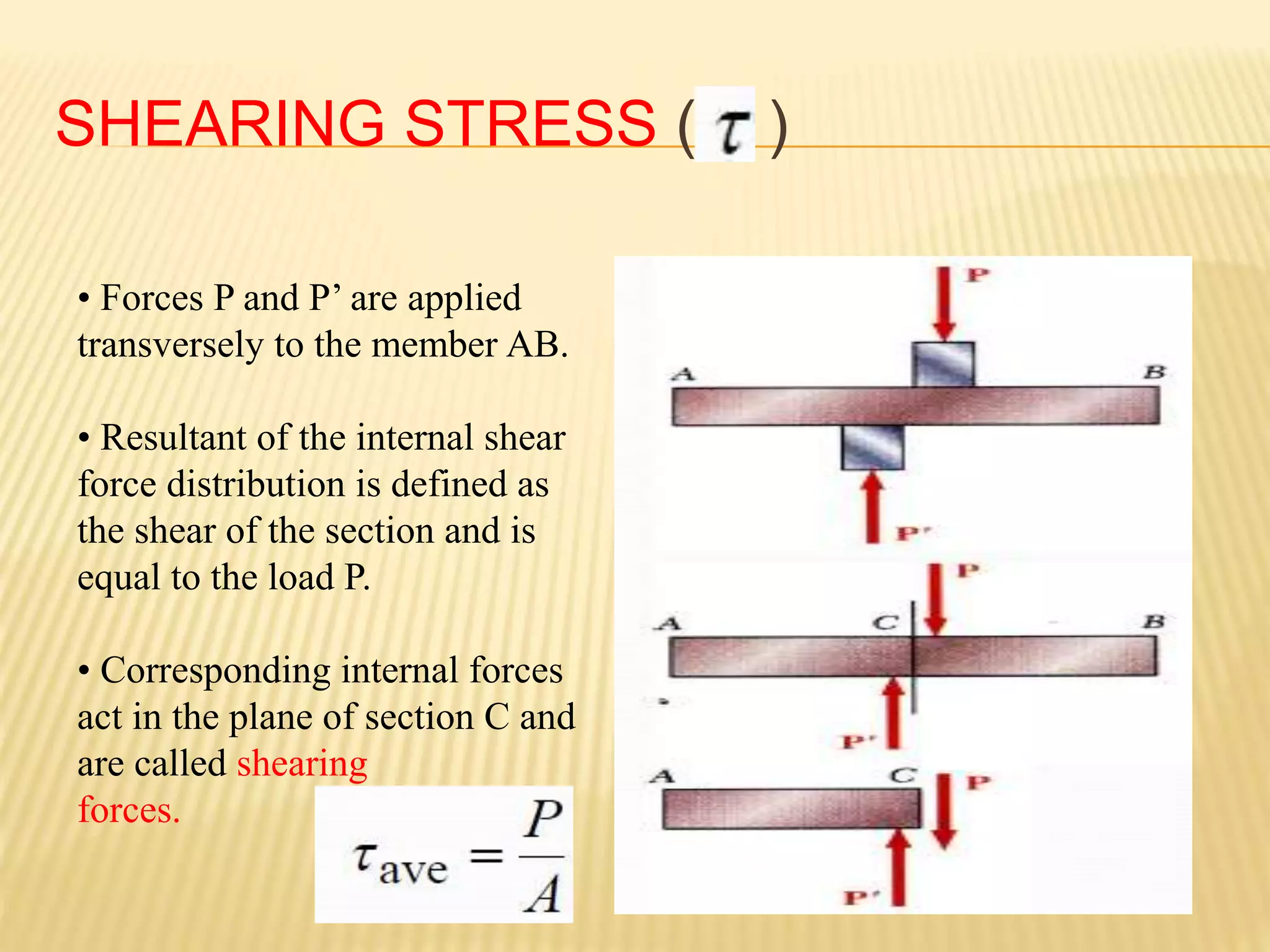

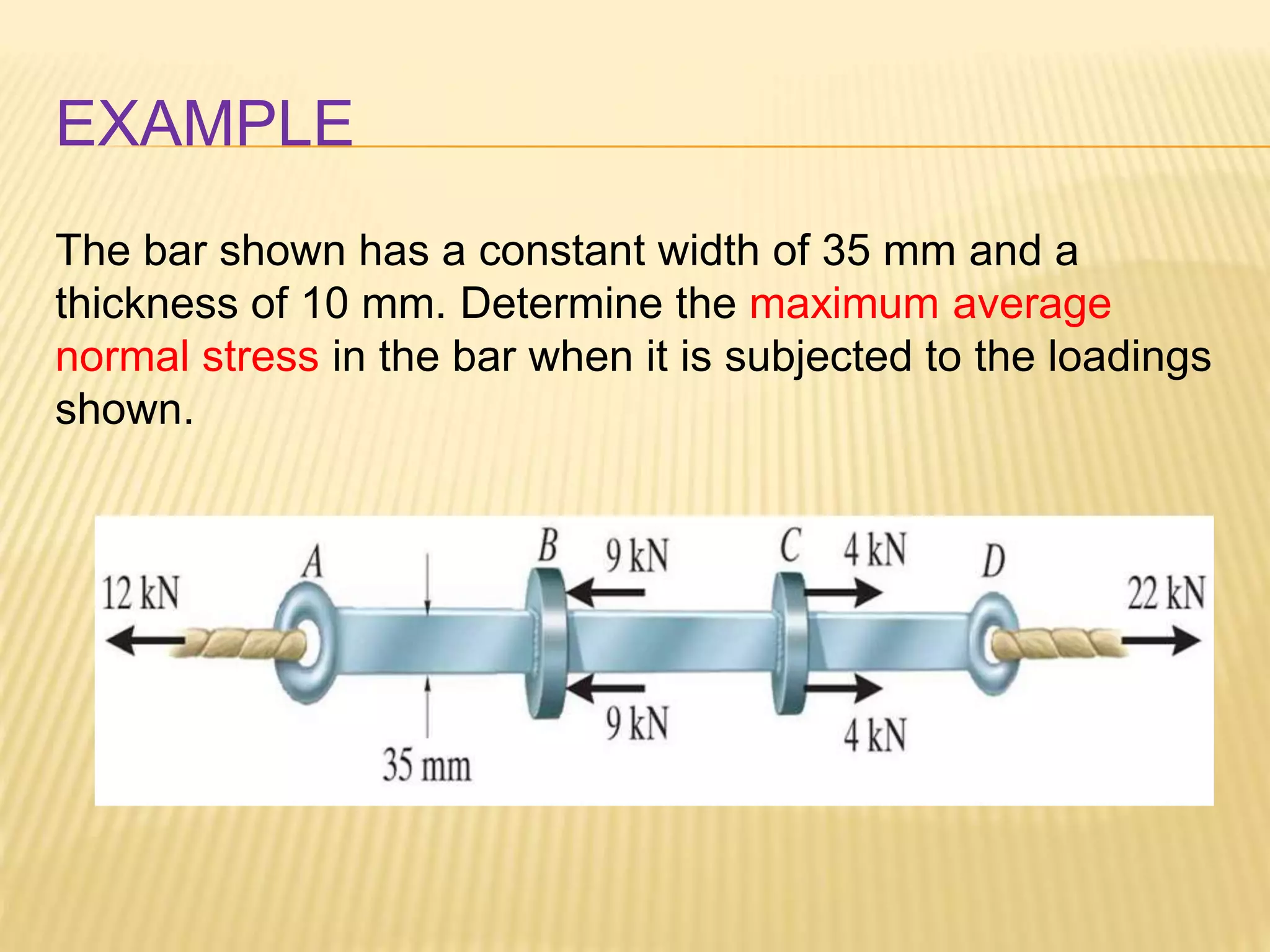

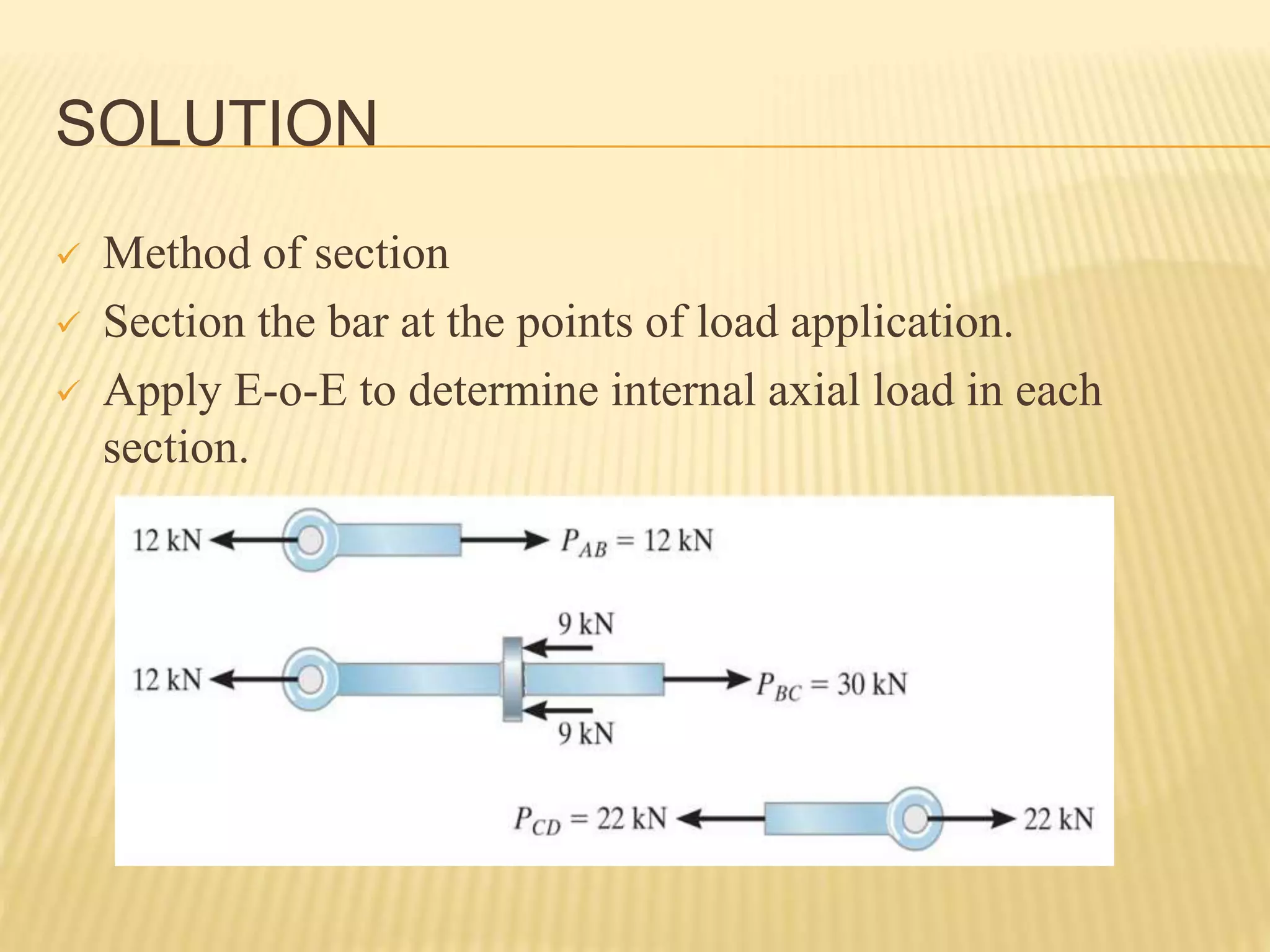

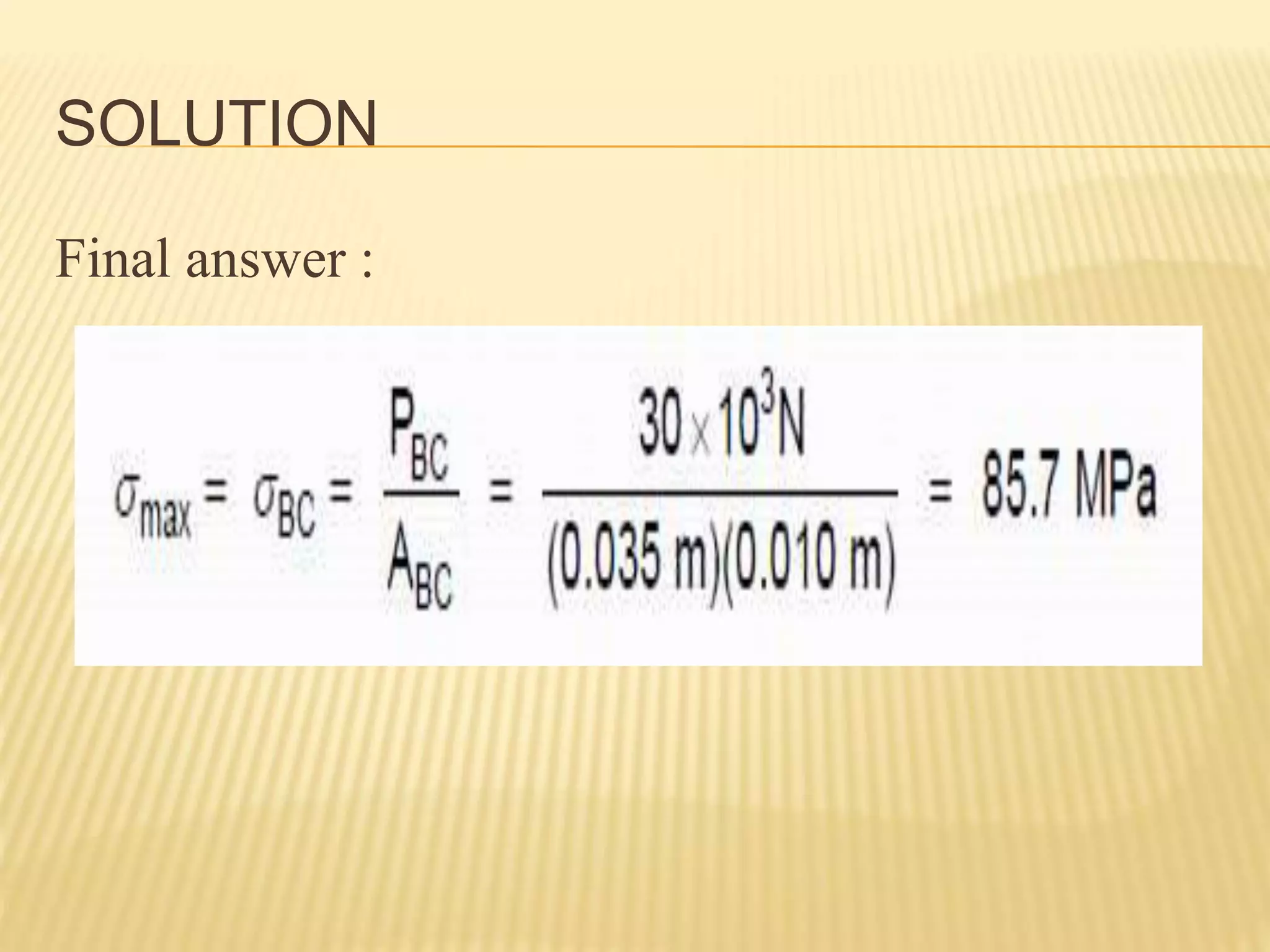

This document provides an introduction to stress and structural analysis. It begins with an overview of statics concepts such as force resolution, addition of forces, moments, and free body diagrams. It then discusses stress in structural members, including normal and shear stress. It covers analysis methods for trusses using the joint and section methods. The document provides examples of applying these concepts to solve for support reactions, internal member forces, and stresses in axially loaded members.