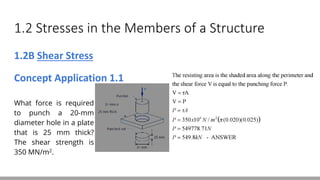

Here are the steps to solve this problem:

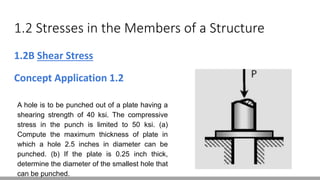

(a) Given: Shear strength = 40 ksi

Diameter of hole = 2.5 in

Compressive stress limit in punch = 50 ksi

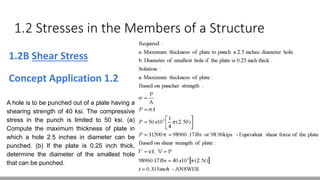

Use the punching shear formula to find the maximum thickness:

τ = P/A = 50 ksi

A = πDh/4

Solve for h:

h = 4P/(πDτ) = 4(50 ksi)/(π(2.5 in)(40 ksi)) = 0.625 in

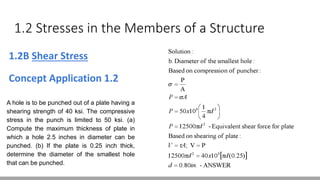

(b) Given: Thickness = 0.25 in

Shear strength = 40 ksi

Compressive stress limit = 50 ksi

Use the