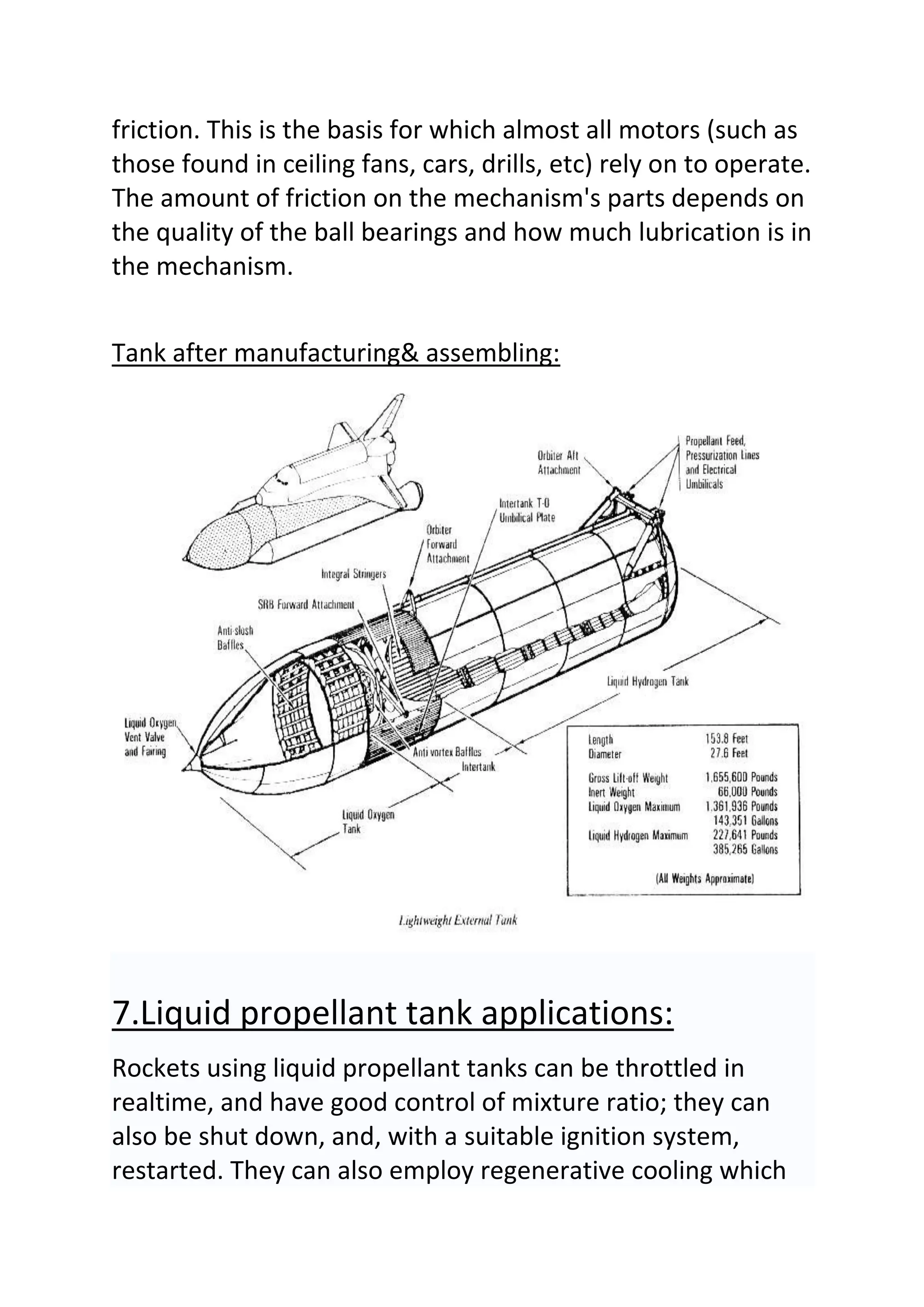

The document discusses the manufacturing process of liquid propellant tanks used in rockets. It describes the key design requirements, including withstanding pressure while being lightweight. The tanks are made of aluminum alloy and consist of domes, cylindrical shells, and other components joined by welding. The manufacturing processes for each component are detailed, including forging, drilling, welding, rolling, and hydroforming. The complete tank assembly process is also outlined.