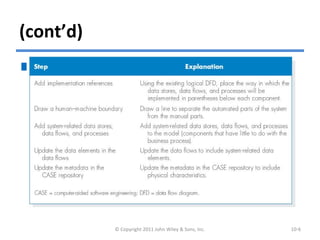

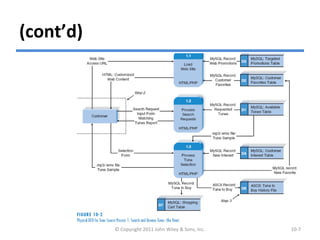

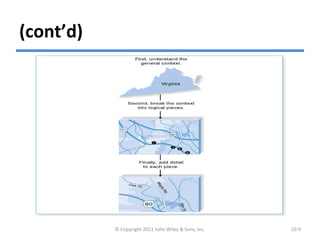

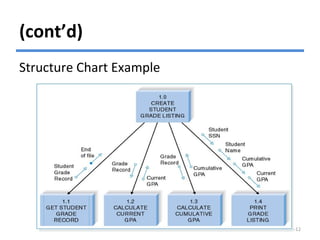

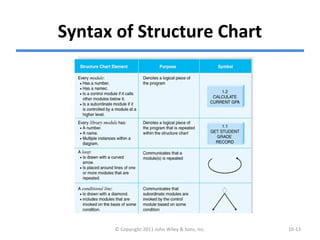

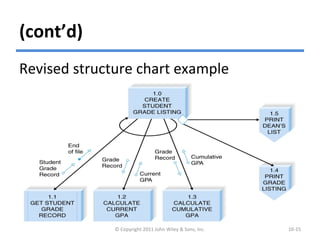

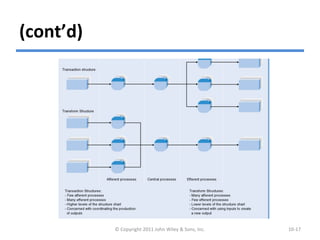

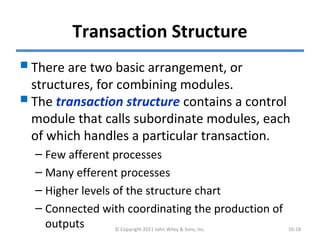

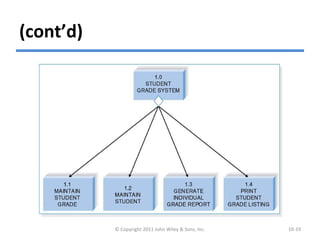

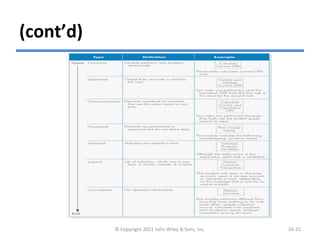

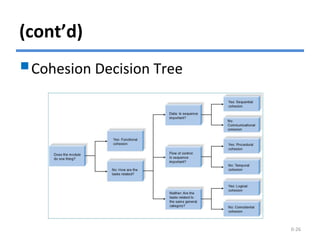

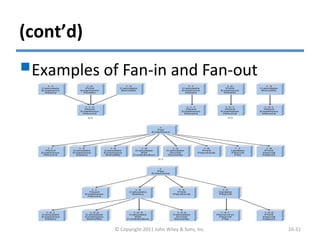

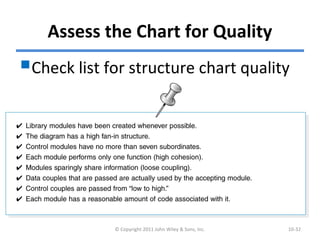

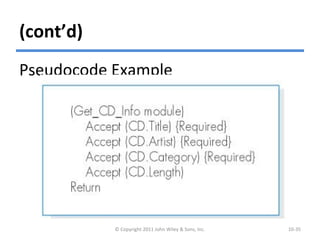

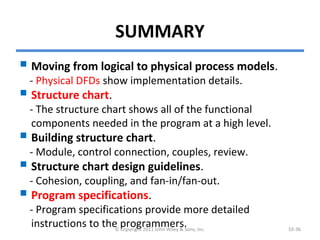

The chapter discusses program design which involves determining programs to write and creating instructions for programmers. It covers moving from logical to physical process models by adding implementation details to DFDs. Program design is done using a top-down modular approach including a structure chart to show program organization and interaction, and program specifications with detailed instructions for programmers. The structure chart is created from the DFDs and design guidelines are provided for cohesion, coupling and fan-in/fan-out.