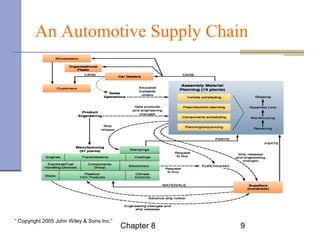

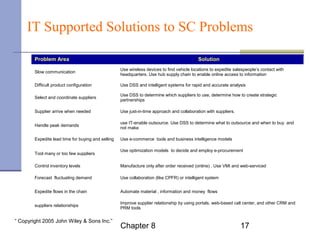

This chapter discusses enterprise systems and supply chain management. It covers topics like enterprise resource planning (ERP), supply chain management (SCM), customer relationship management (CRM), and how information technology supports integrating activities along the supply chain. The chapter also addresses problems in managing supply chains like uncertainties and the bullwhip effect, and presents solutions like information sharing, vendor-managed inventory, and collaboration. It describes computerized systems that helped solve supply chain problems, like MRP, MRPII, and how ERP software integrates planning across the entire enterprise.