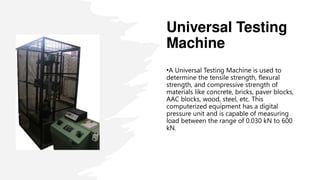

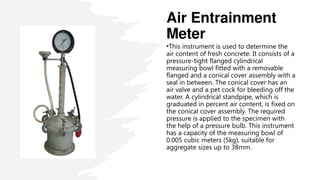

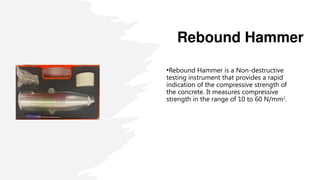

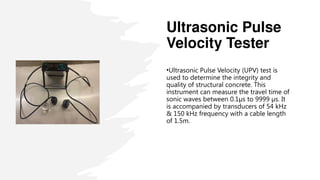

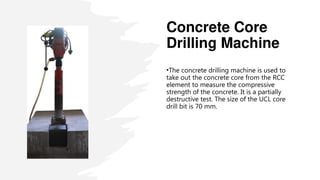

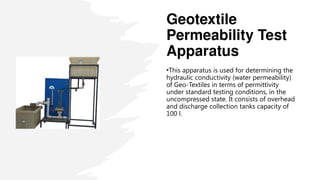

The document outlines various instruments used in a material testing laboratory, including their functions and measurement capabilities. Key instruments mentioned include the universal testing machine for strength measurements, mortar vibrating machine for compacting mortar, and tools for assessing concrete properties such as workability, air content, and permeability. Each instrument is designed for specific tests to evaluate the quality and performance of construction materials.