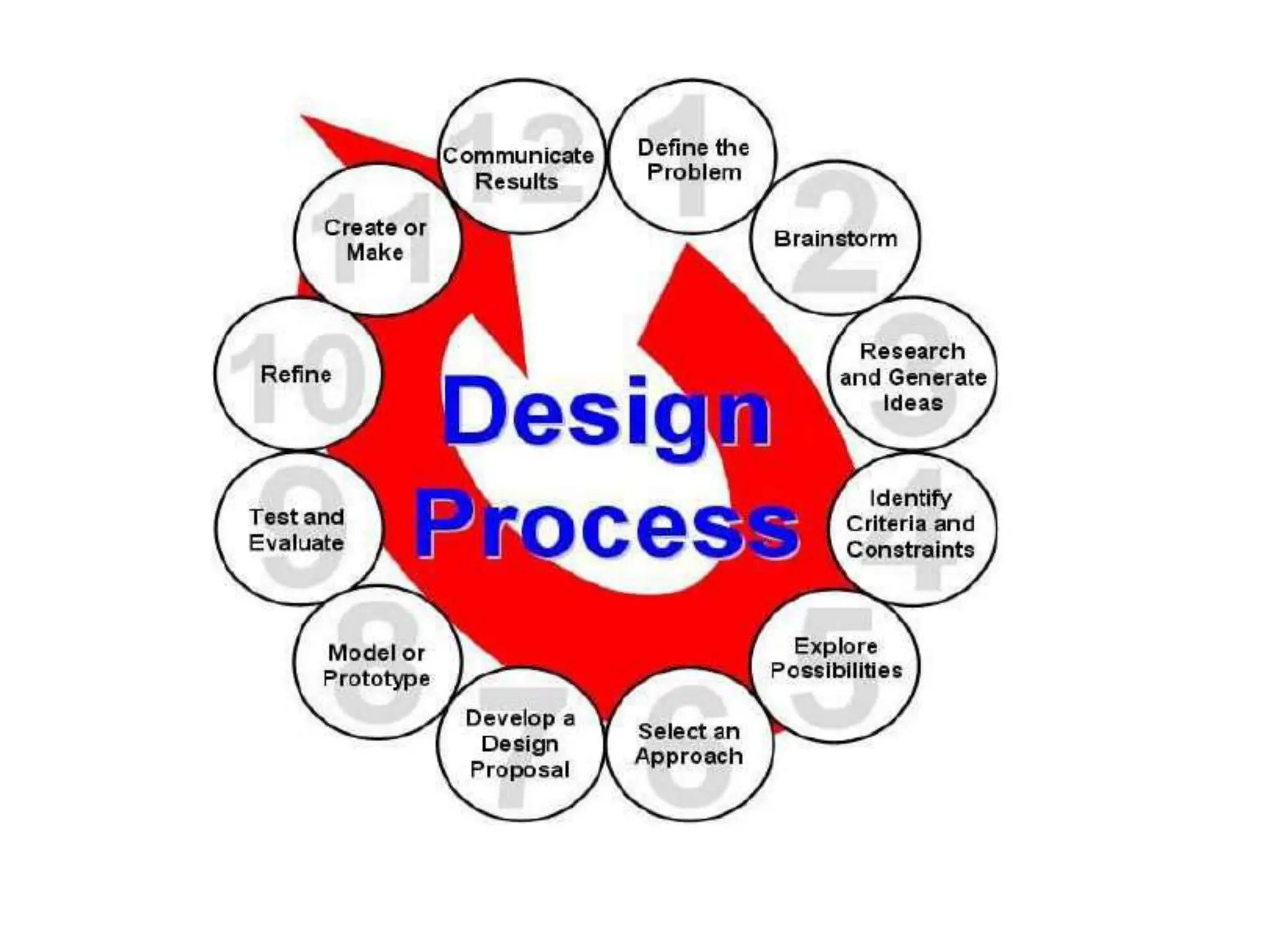

The document outlines the engineering design process, emphasizing the importance of information acquisition and iteration in developing effective designs. It discusses the need for general and specific information, the evaluation of design outcomes, and the iterative nature of design, which allows for refinements based on previous results. Additionally, it notes that many designs are often halted due to feasibility concerns, yet they contribute valuable information for future use.