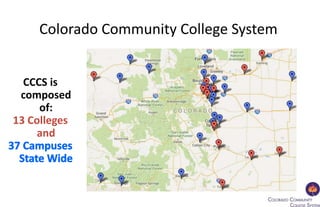

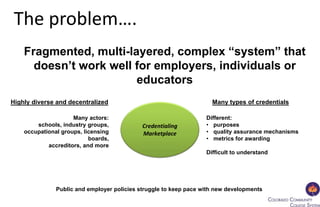

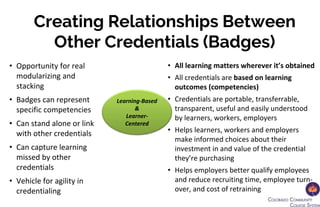

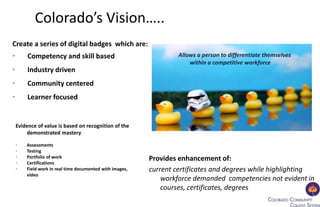

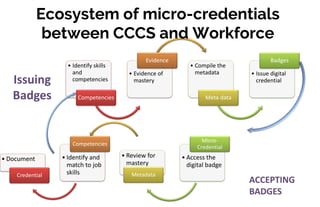

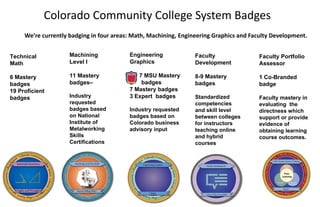

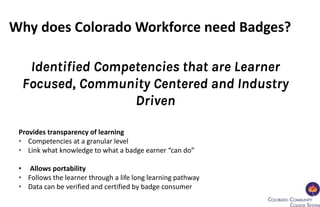

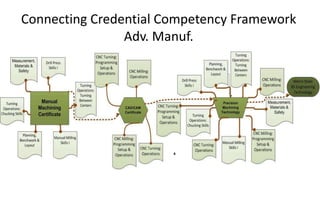

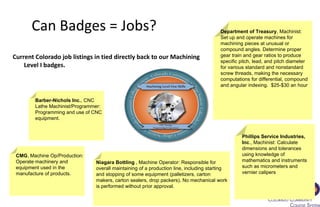

This document discusses the use of digital badges to recognize skills and competencies in the workforce. It notes that today's credentialing system is complex and difficult to understand for employers, individuals, and educators. Digital badges can provide a learning-based alternative that is learner-centered, competency-based, and industry-driven. The Colorado Community College System is piloting the use of digital badges in several technical areas like math, machining, and engineering graphics. Badges can help provide transparent, portable credentials that map to specific skills and allow learners to showcase competencies across different programs and throughout their careers.