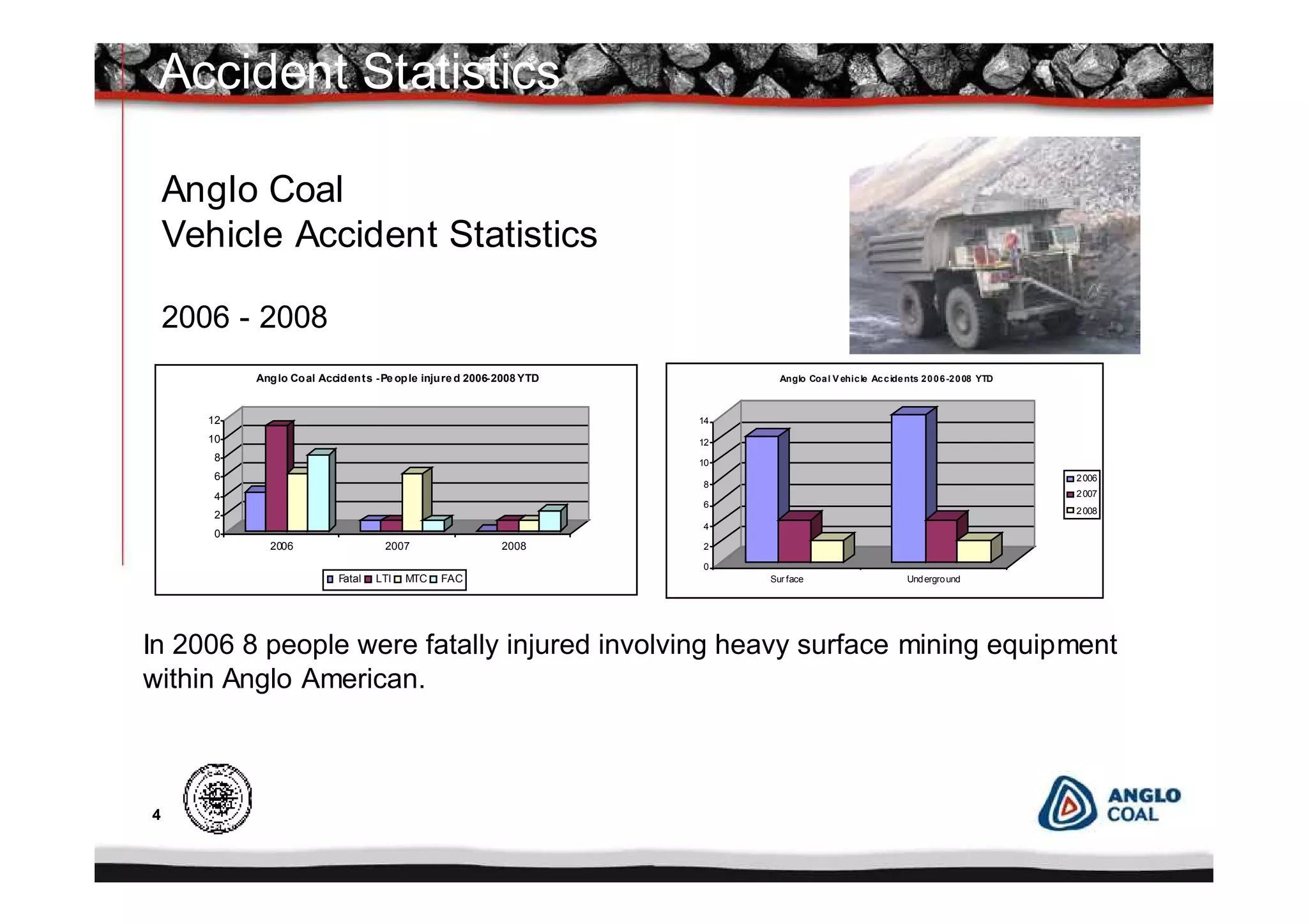

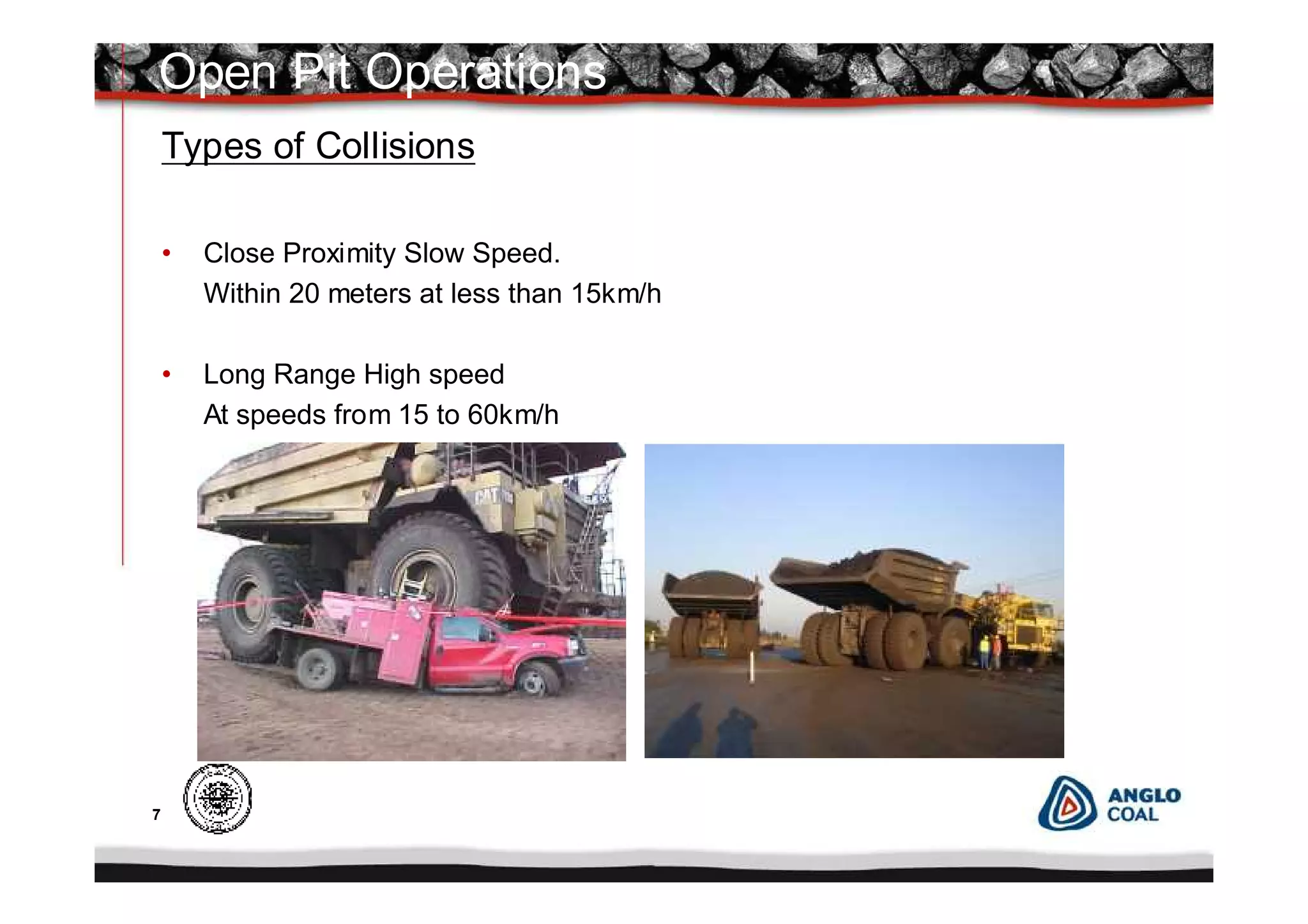

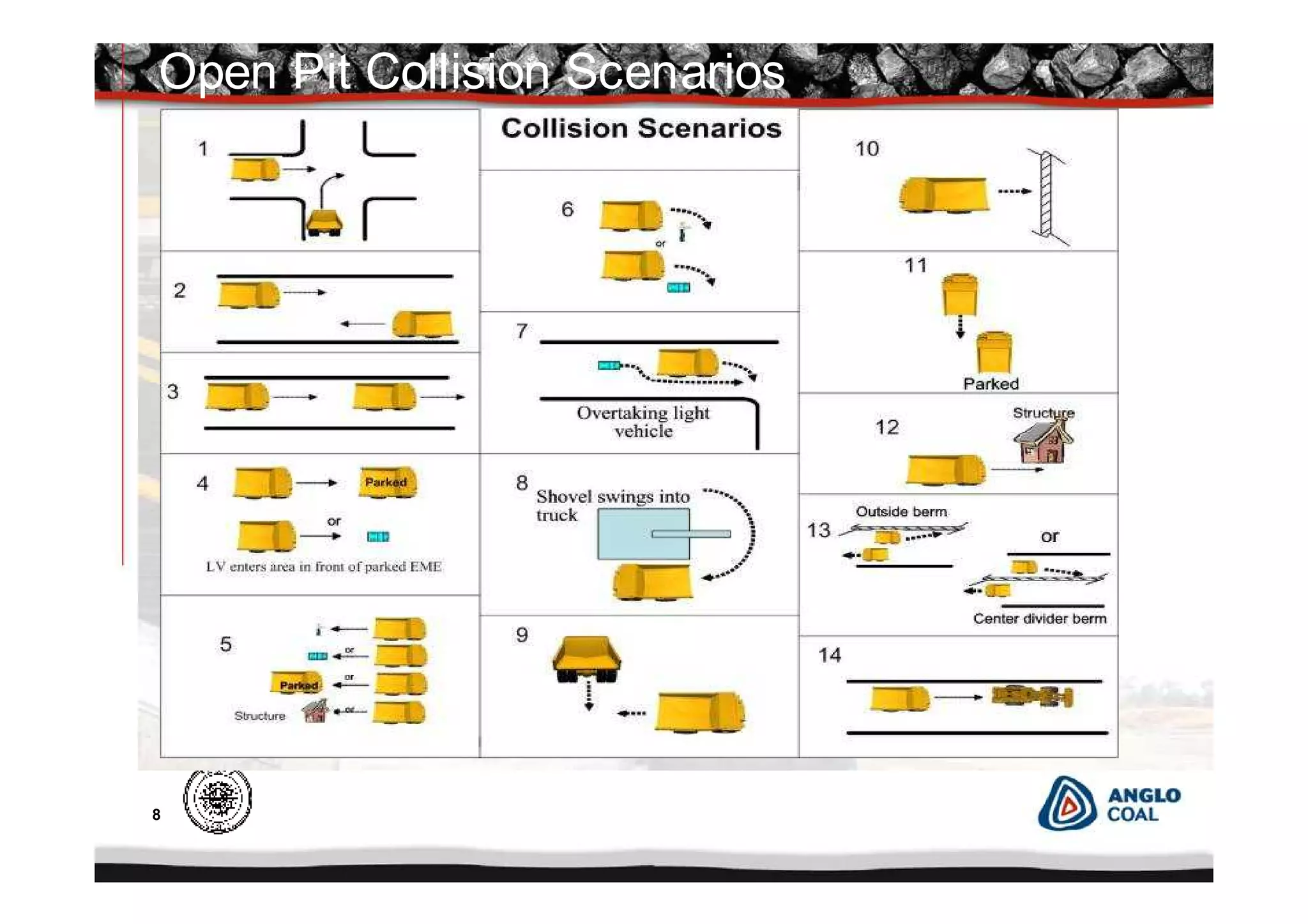

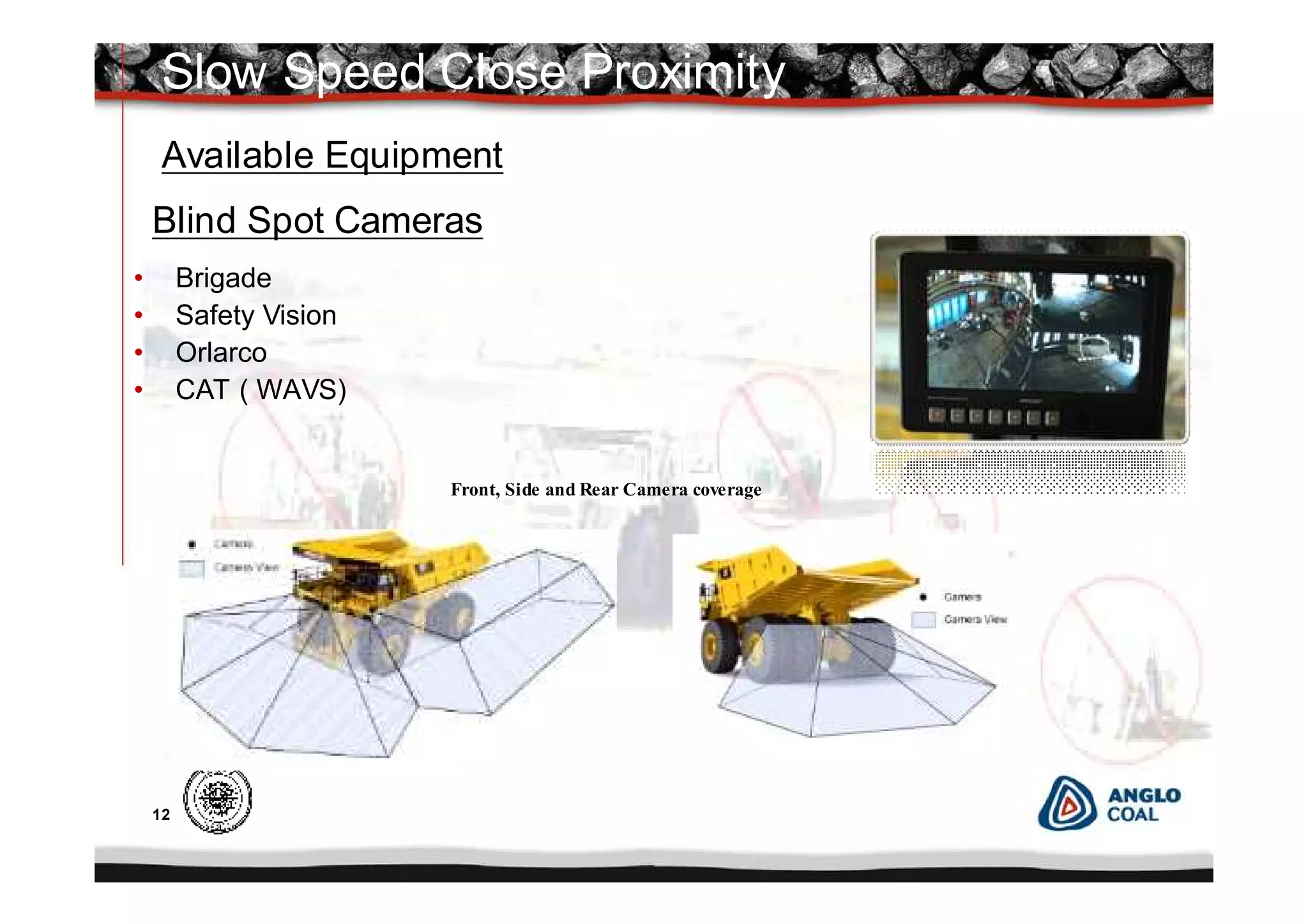

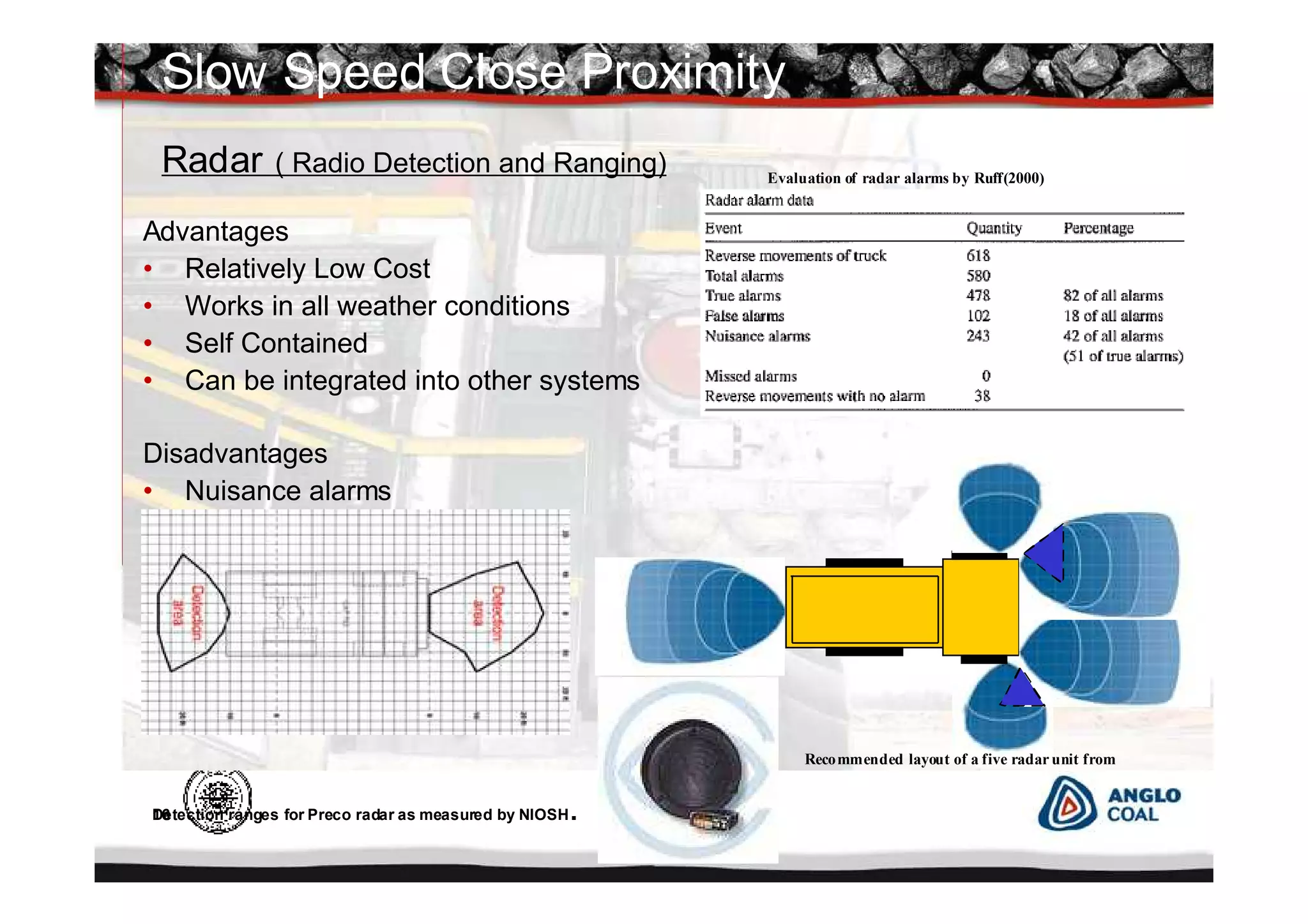

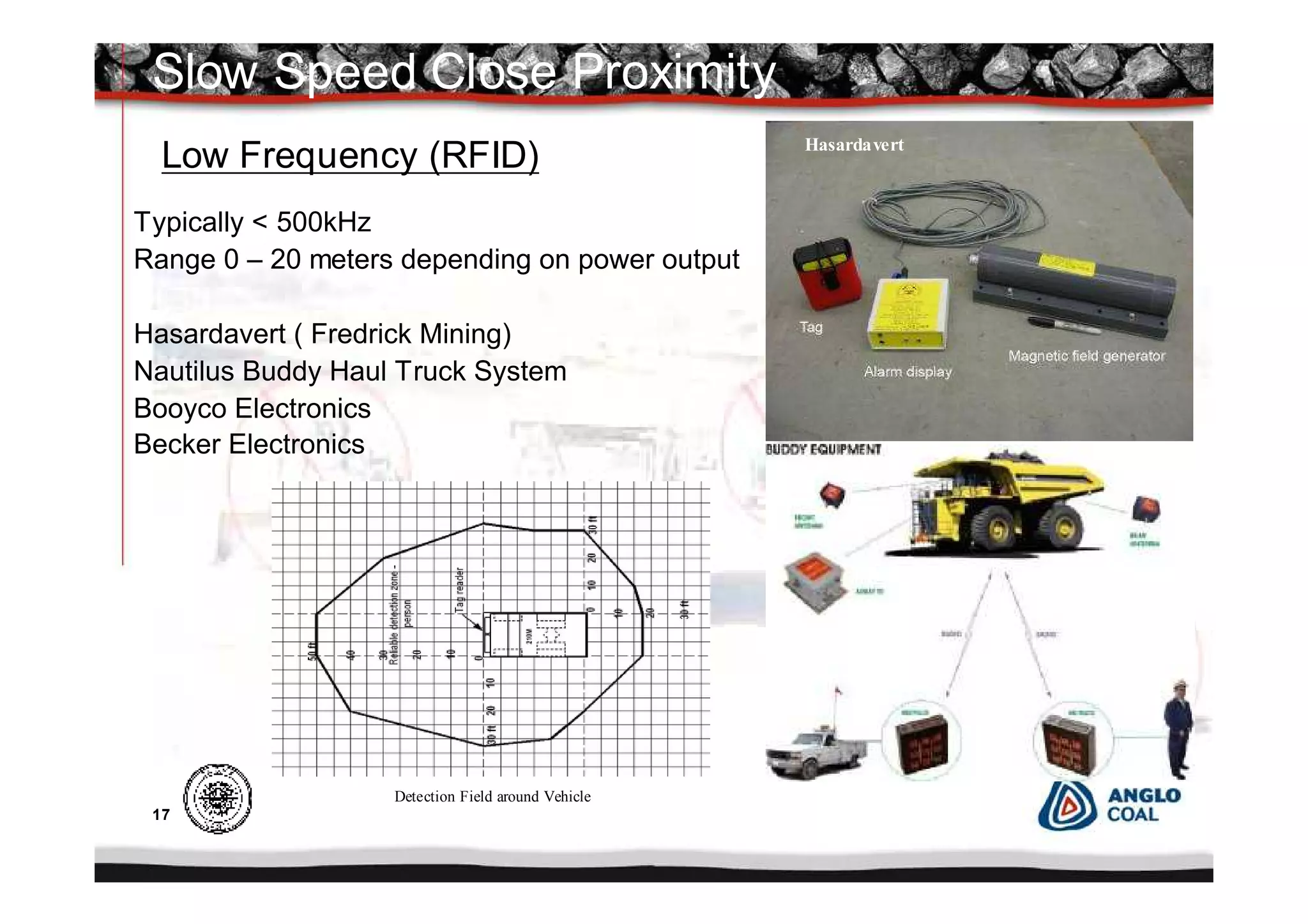

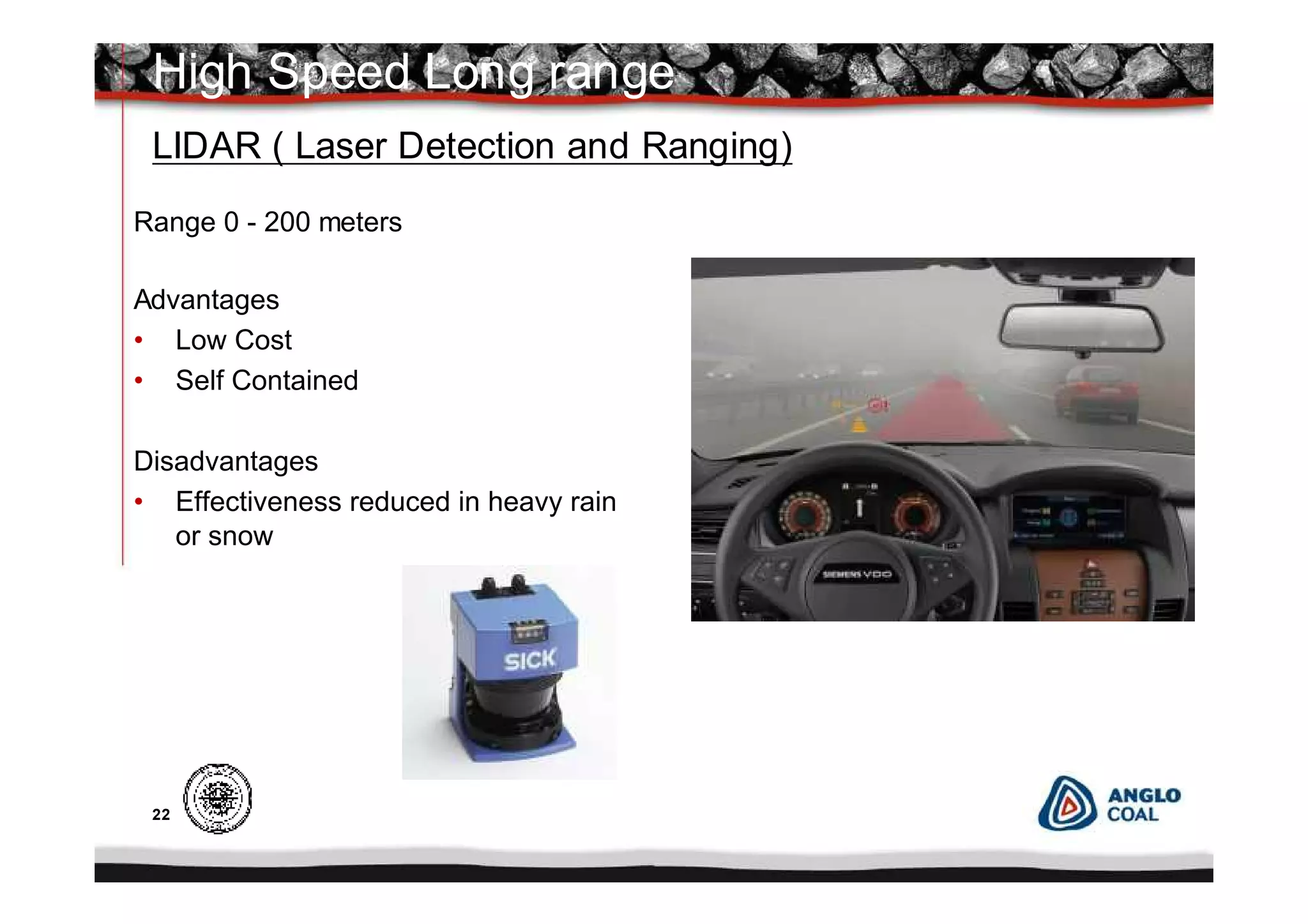

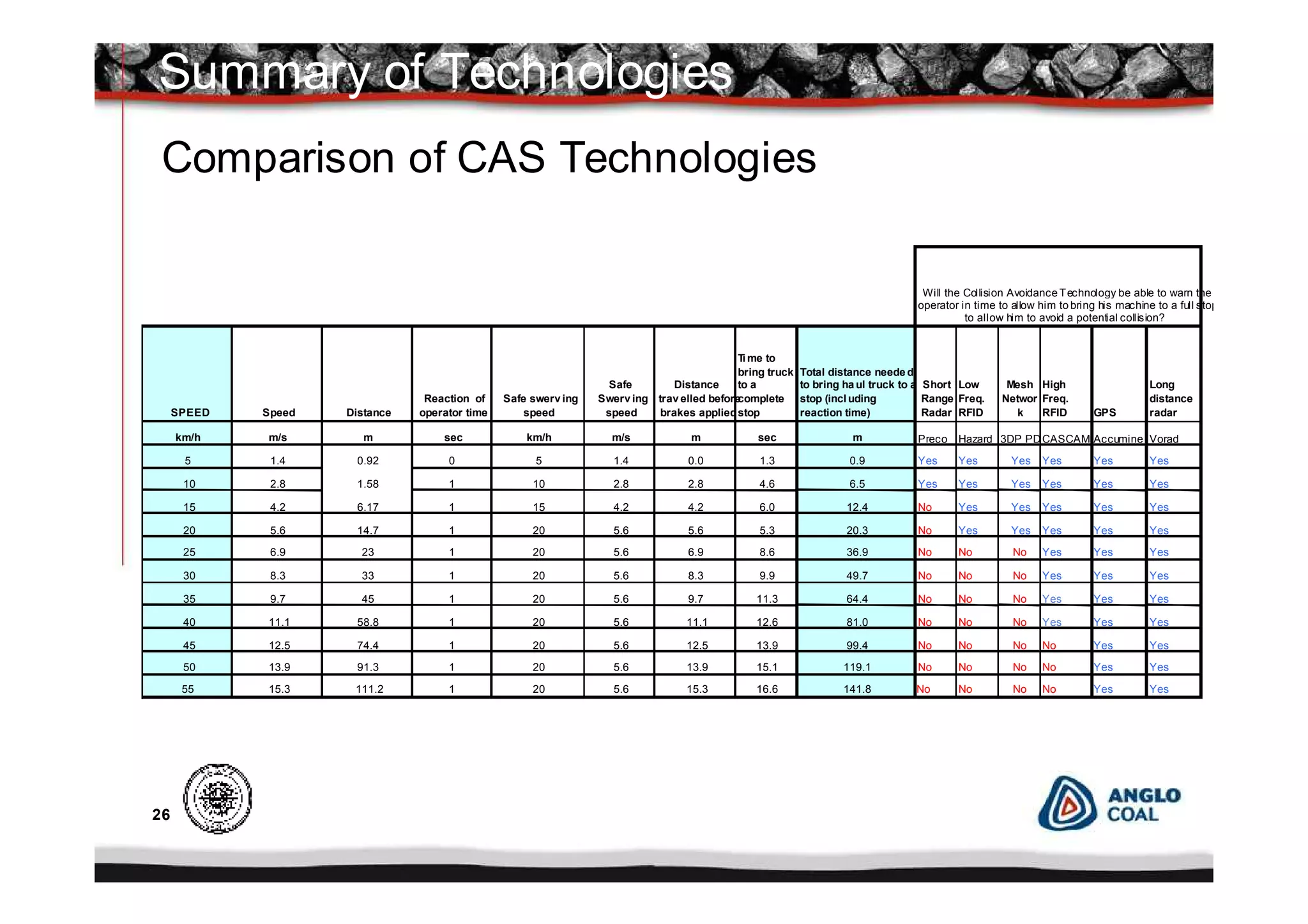

Steven Niven presented on vehicle and personnel collision warning systems for open pit and underground mining operations. He discussed Anglo Coal's accident statistics involving heavy equipment to motivate the need for these systems. He then provided an overview of various collision avoidance technologies currently available, including cameras, radar, RFID, and GPS systems. He detailed Anglo Coal's implementation roadmaps for surface and underground operations, which involved trialling and rolling out different collision warning systems between 2007-2008. The presentation concluded with a discussion of future technologies like adaptive cruise control and lane departure warning that could further improve safety.