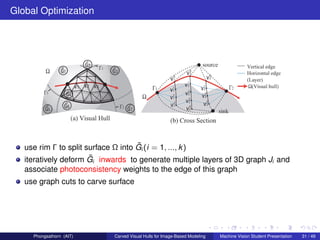

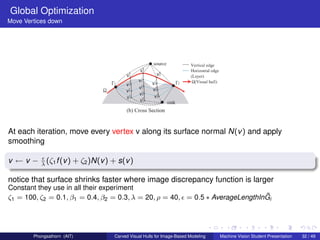

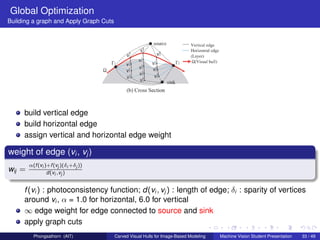

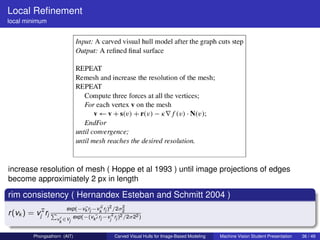

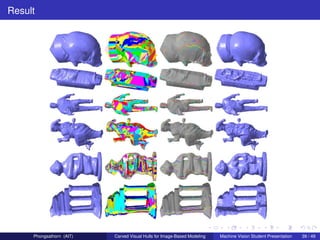

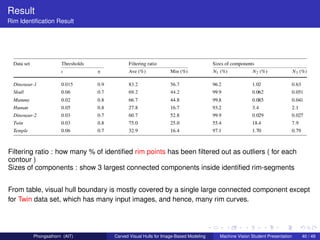

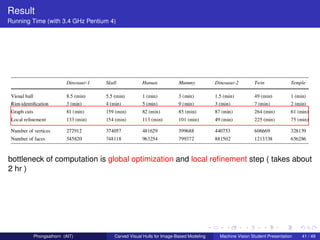

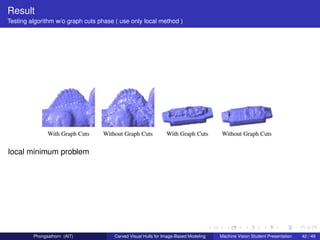

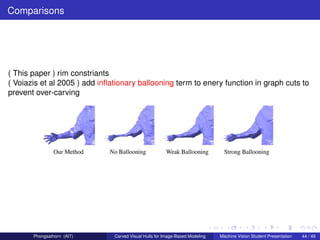

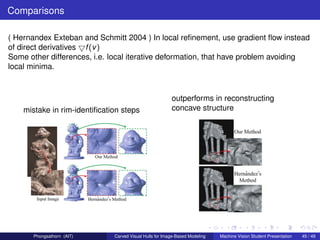

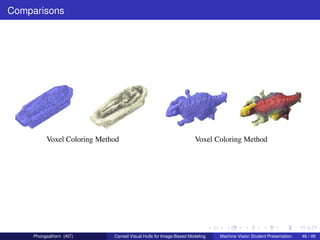

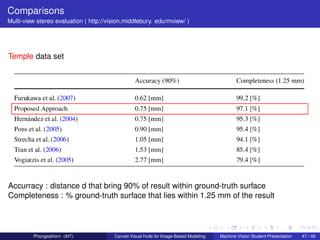

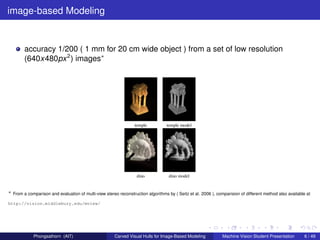

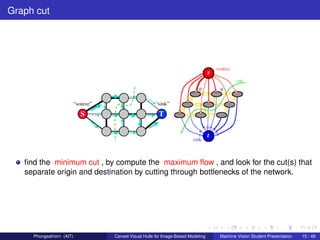

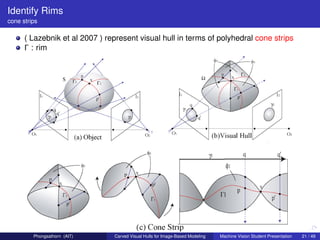

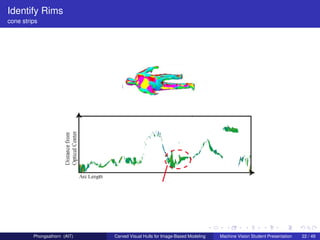

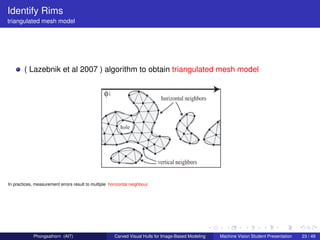

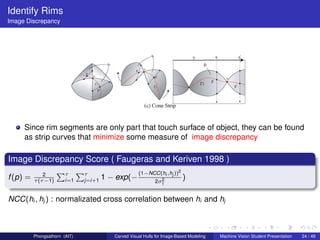

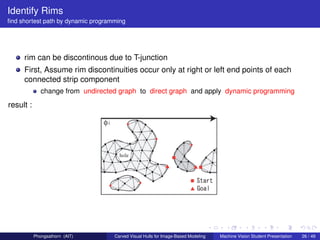

The document summarizes a presentation on carved visual hulls for image-based modeling. It discusses how the method uses a set of images to identify rims around the object's silhouette. It then performs global optimization using graph cuts with the rims as constraints, followed by local refinement. The results show accurate reconstructions on several data sets, with running times of around 2 hours for the global and local steps. Comparisons demonstrate it outperforms other methods at reconstructing concave structures.

![Identify Rims

remove false rim segmentation

assumption break at complicated structure i.e. the fold of human cloth

remove false rim segmentation

Among all vertics identified as rim points, filter out false-positives

vertex v is detected as false positive if

either 4Rl < g(v ) or Rl < g(v ) [vertical size is too large] and

f ∗ (v ) < η [vertical size is not small enough] and [average NCC wrose than η]

average NCC score ( Faugeras and Keriven 1998 )

Pτ Pτ

f ∗ (p) = 2

τ (τ −1) i=1 j=i+1 NCC(hi , hj )

Phongsathorn (AIT) Carved Visual Hulls for Image-Based Modeling Machine Vision Student Presentation 27 / 49](https://image.slidesharecdn.com/generic-ornate-15min-45min-en-090728041609-phpapp01/85/Carved-Visual-Hulls-for-Image-Based-Modeling-27-320.jpg)