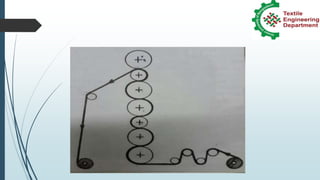

This presentation summarizes the process of calendering finishing. It is presented to Mutasim Uddin, Lecturer at Green University of Bangladesh by 4 students. The presentation defines calendering as compressing fabric between rollers under controlled temperature and pressure. The objectives are to improve fabric hand, reduce thickness, improve opacity, reduce air permeability, and impart lustre. The document describes preparation, types of calendering machines including ordinary, swizzing, friction, schreiner, and embossing calenders. It provides examples and advantages of calendering fabrics.