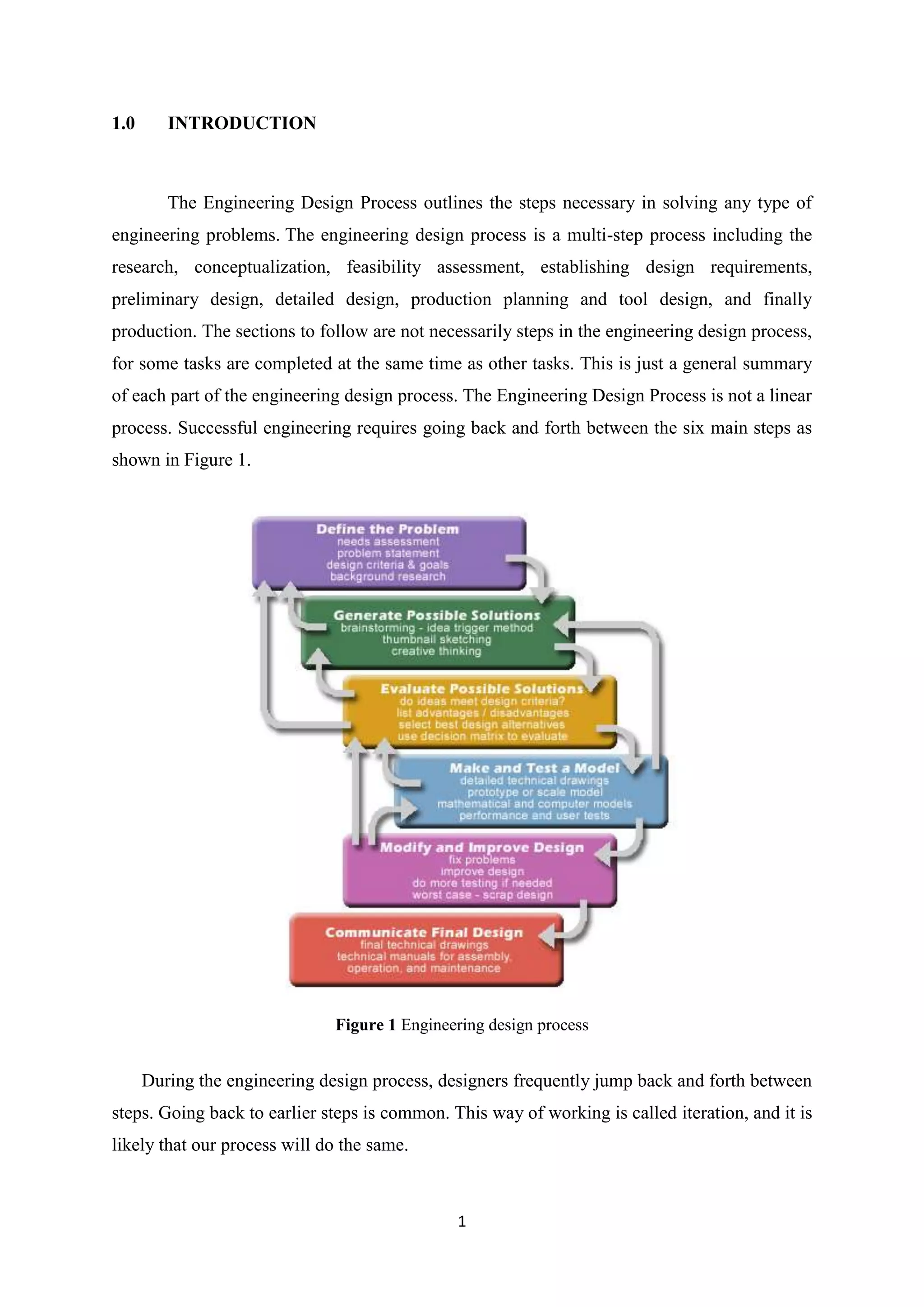

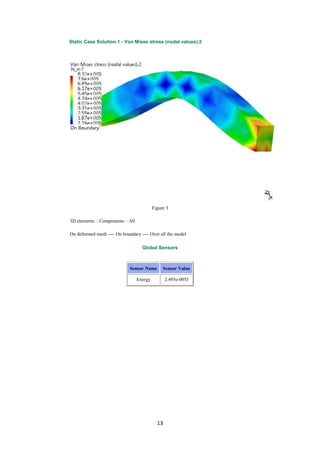

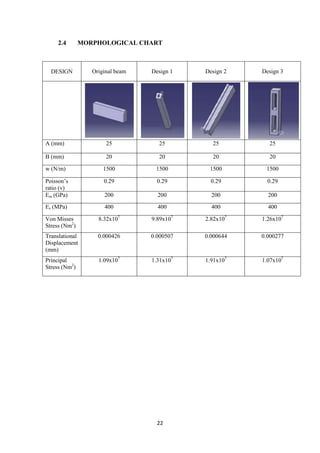

The document describes the engineering design process and finite element analysis (FEA). It summarizes that the engineering design process is iterative and involves research, conceptualization, design, and production. It then explains that FEA uses the finite element method to approximate solutions to partial differential equations by dividing a complex problem into smaller, solvable elements. FEA is well-suited for problems over complicated domains, changing domains, solutions with varying precision, or non-smooth solutions like crash simulations.