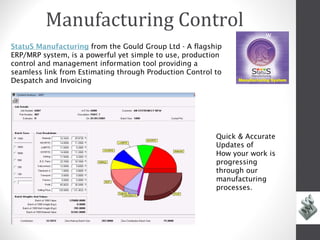

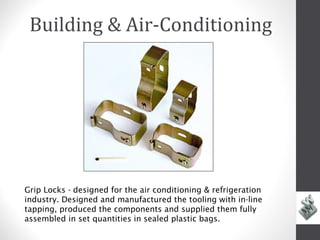

Westley Engineering specializes in precision machining and contract pressings, blending traditional craftsmanship with advanced technology for high-quality production. The company is ISO certified and utilizes a powerful ERP/MRP system for efficient manufacturing management. Their product offerings include automotive and aerospace components, showcasing their commitment to quality and customer satisfaction.