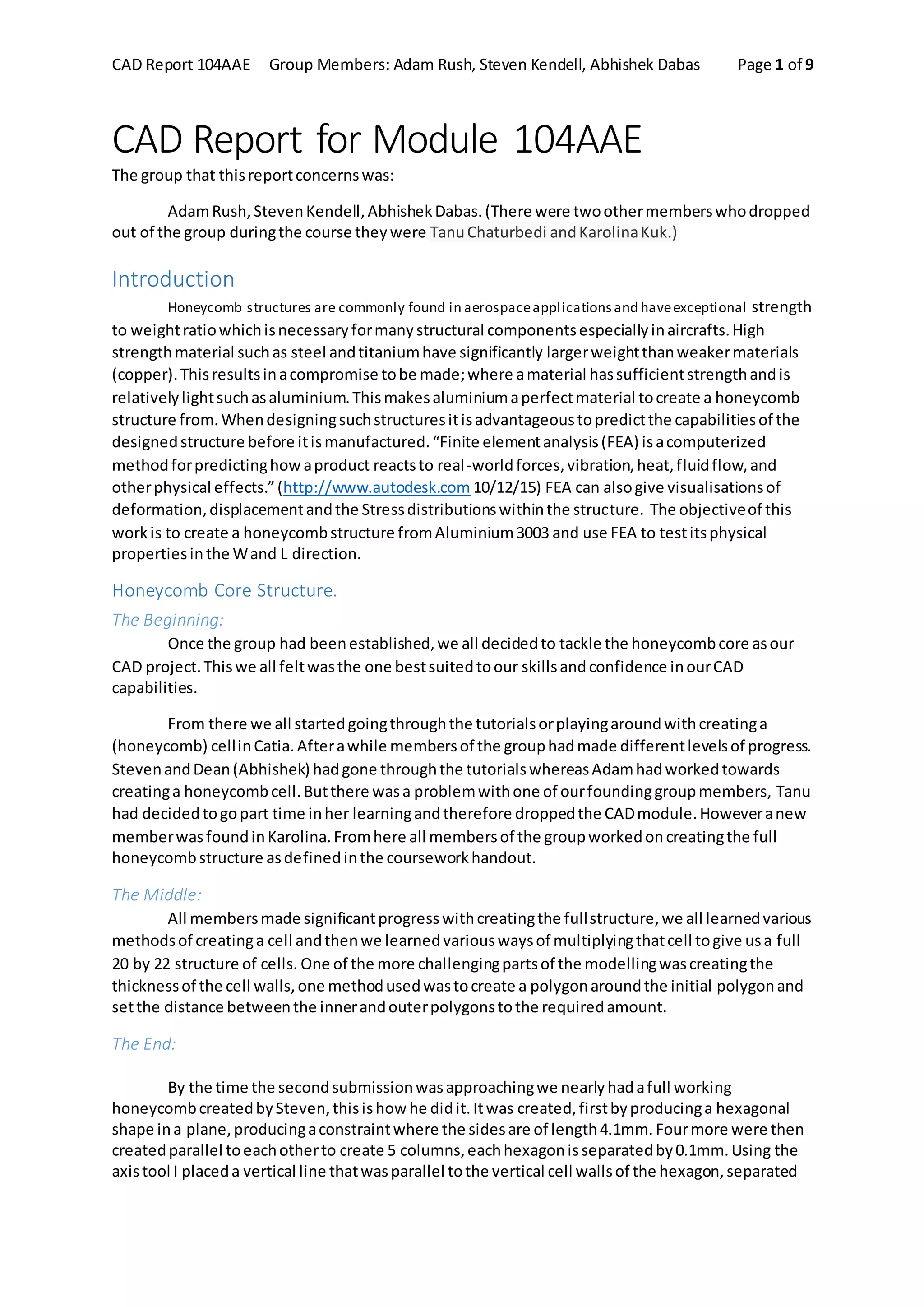

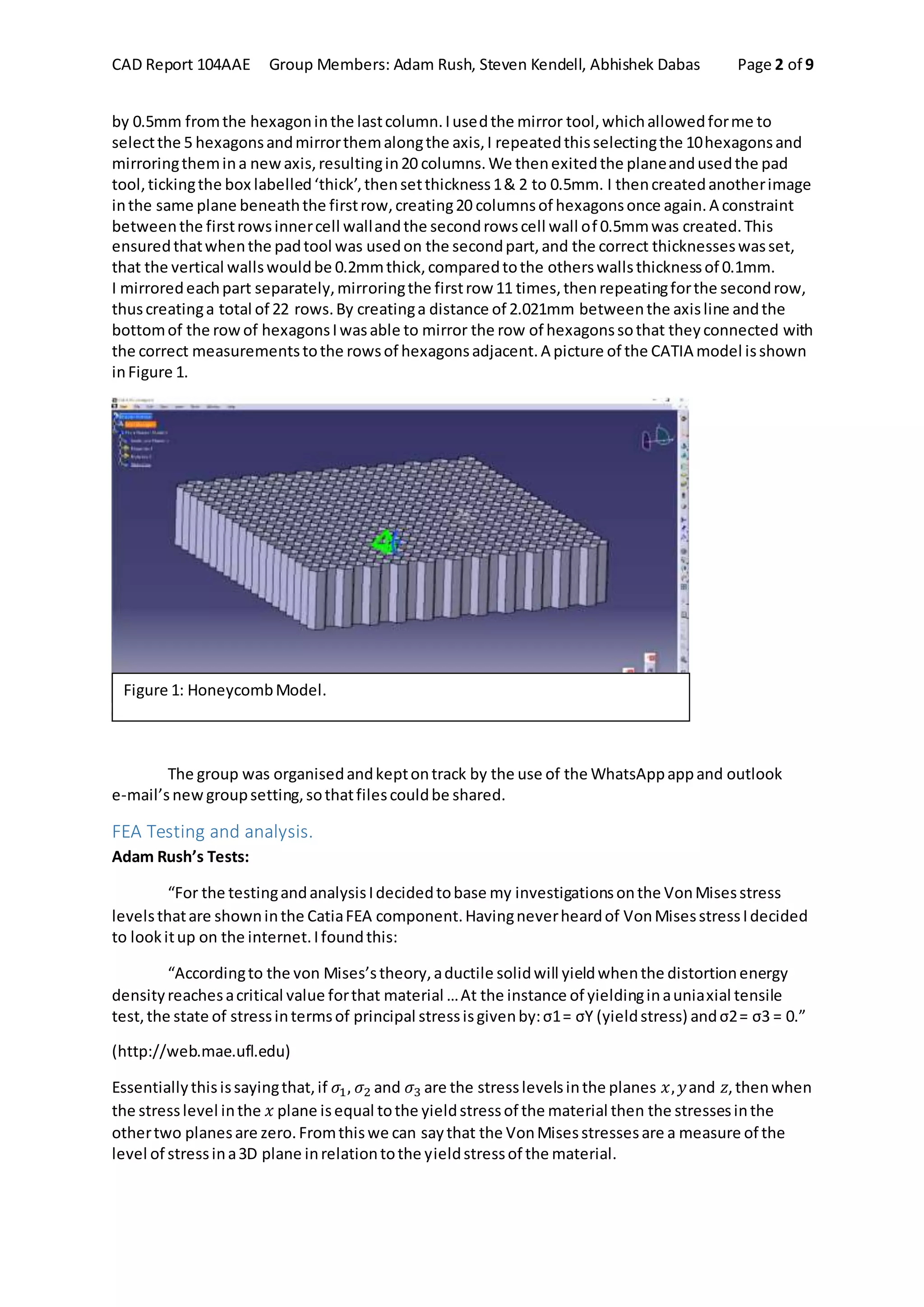

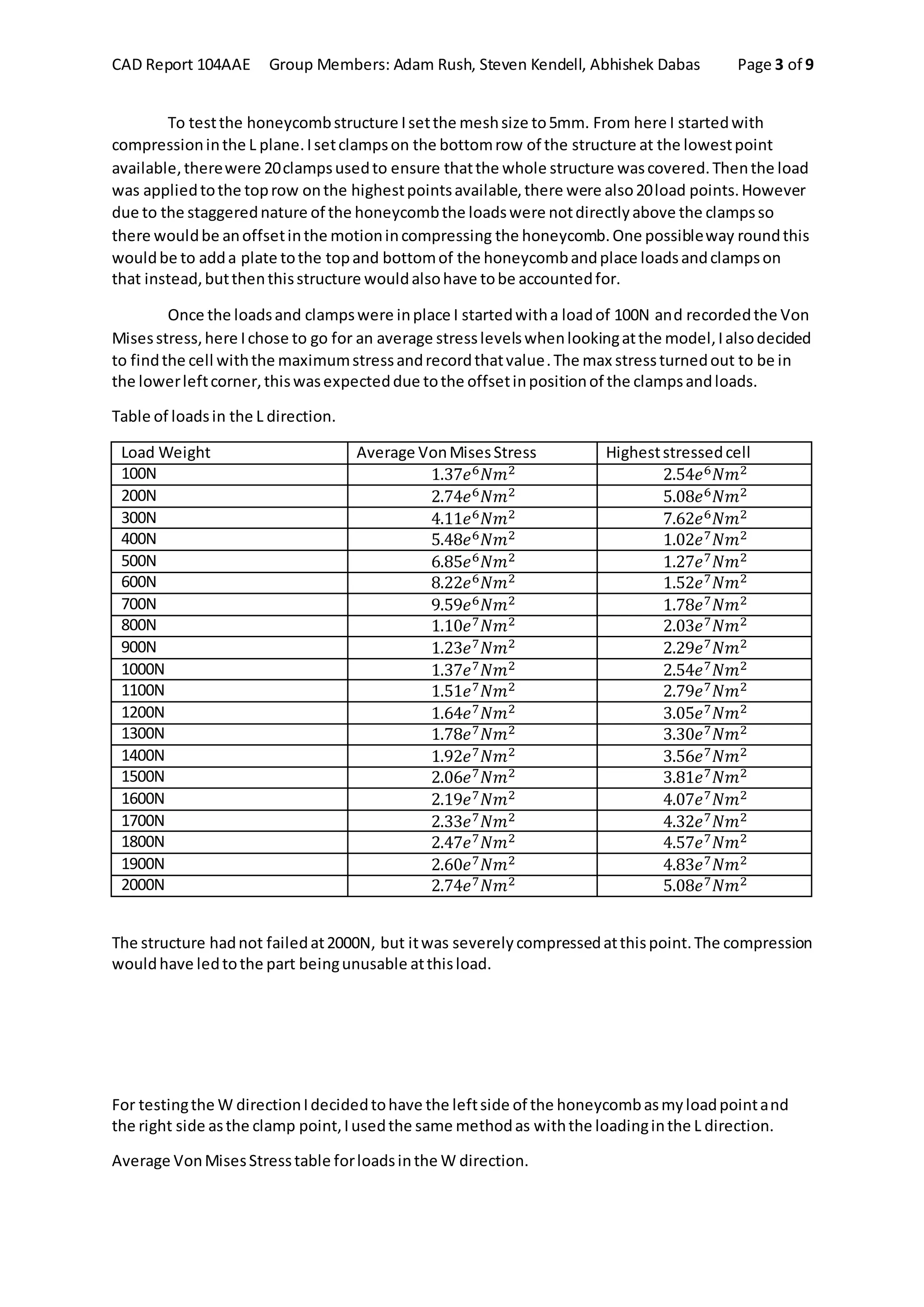

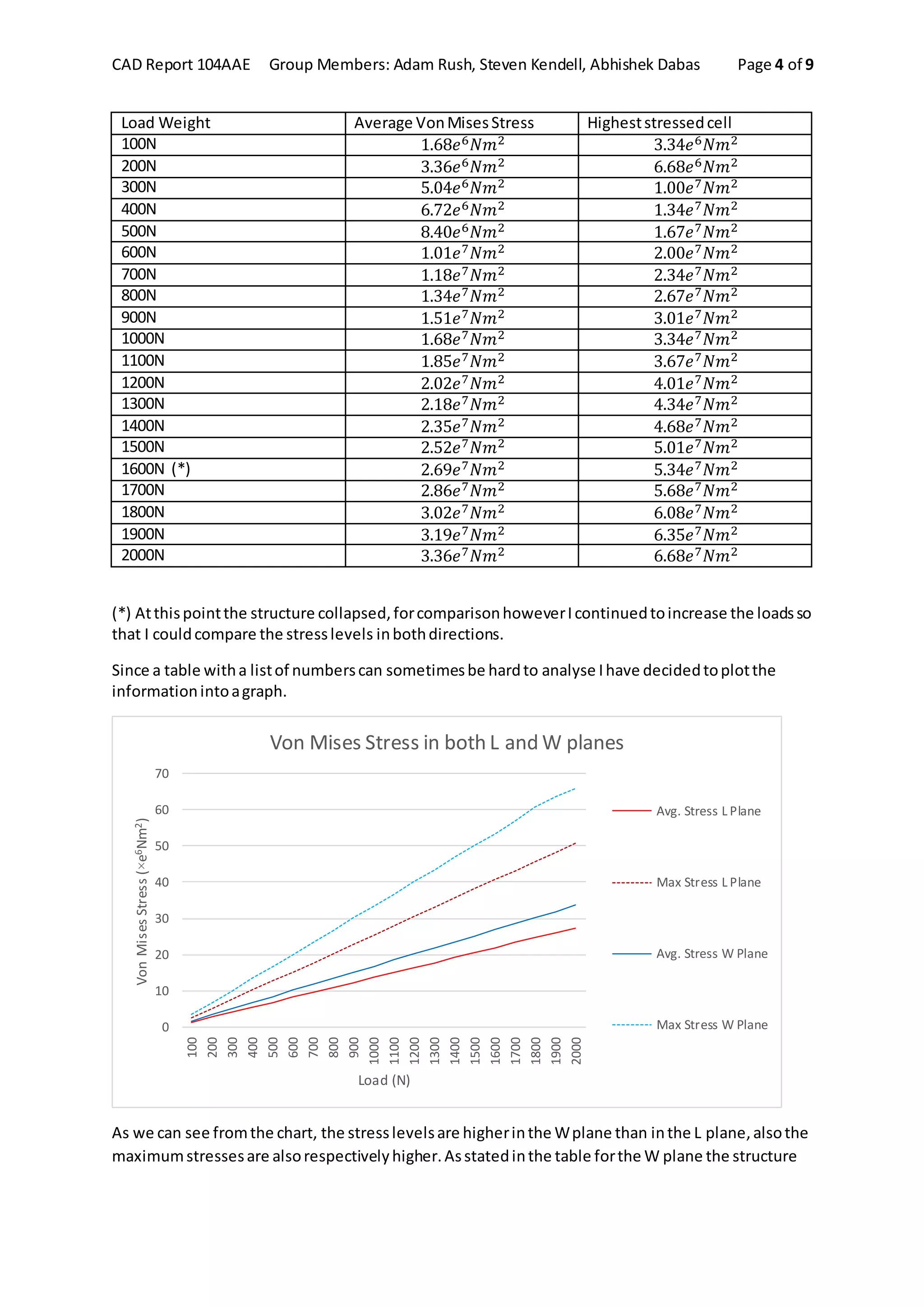

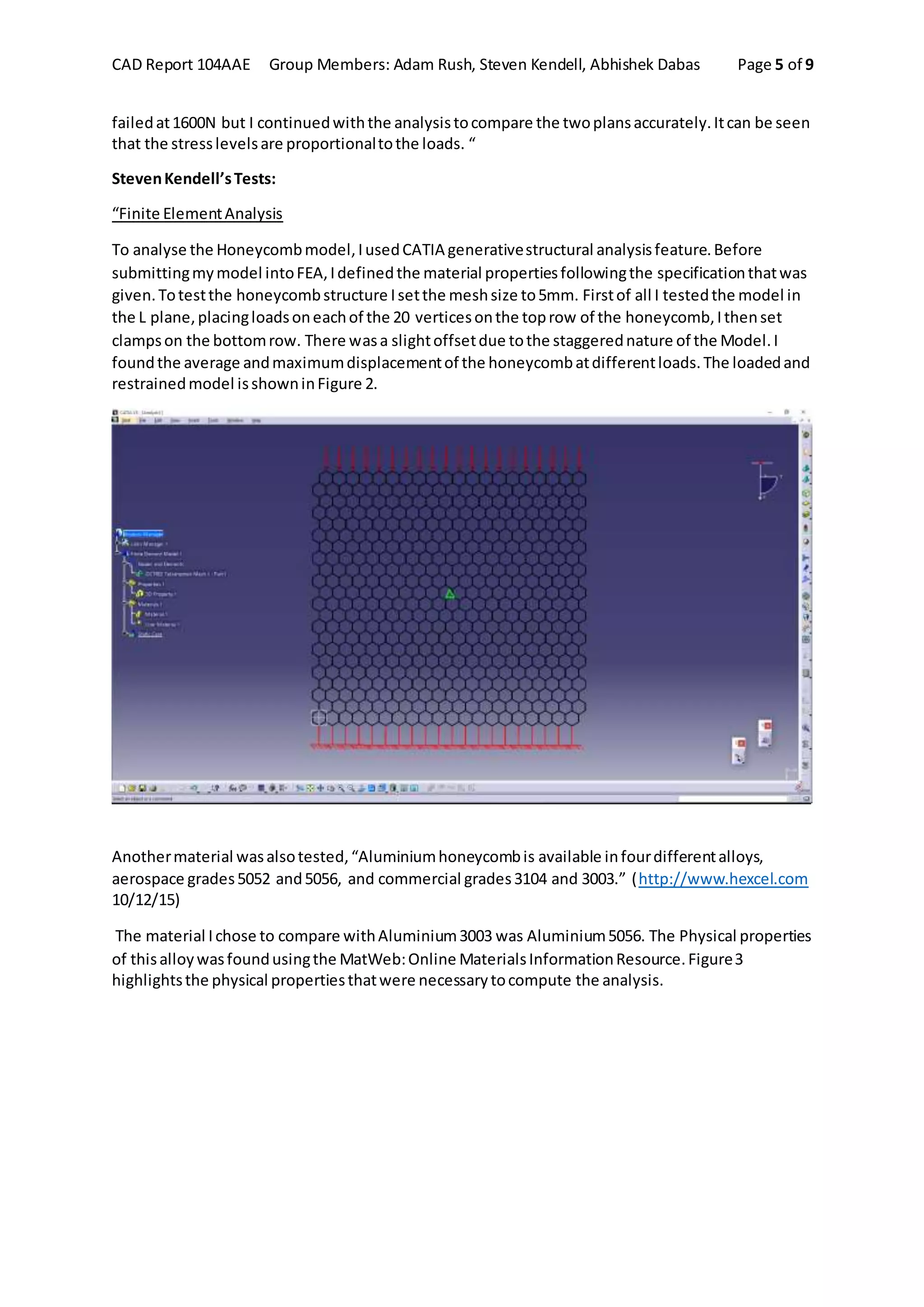

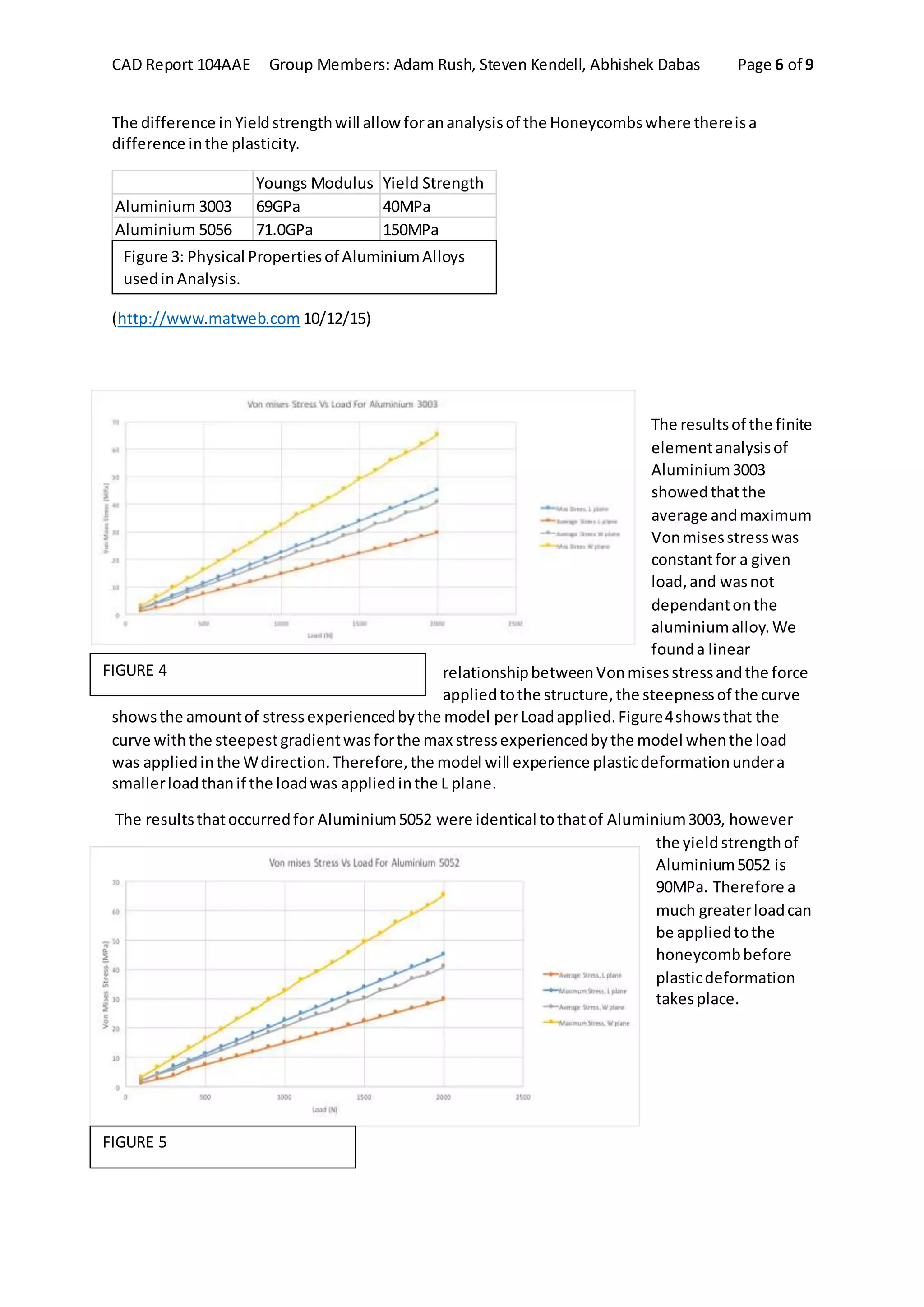

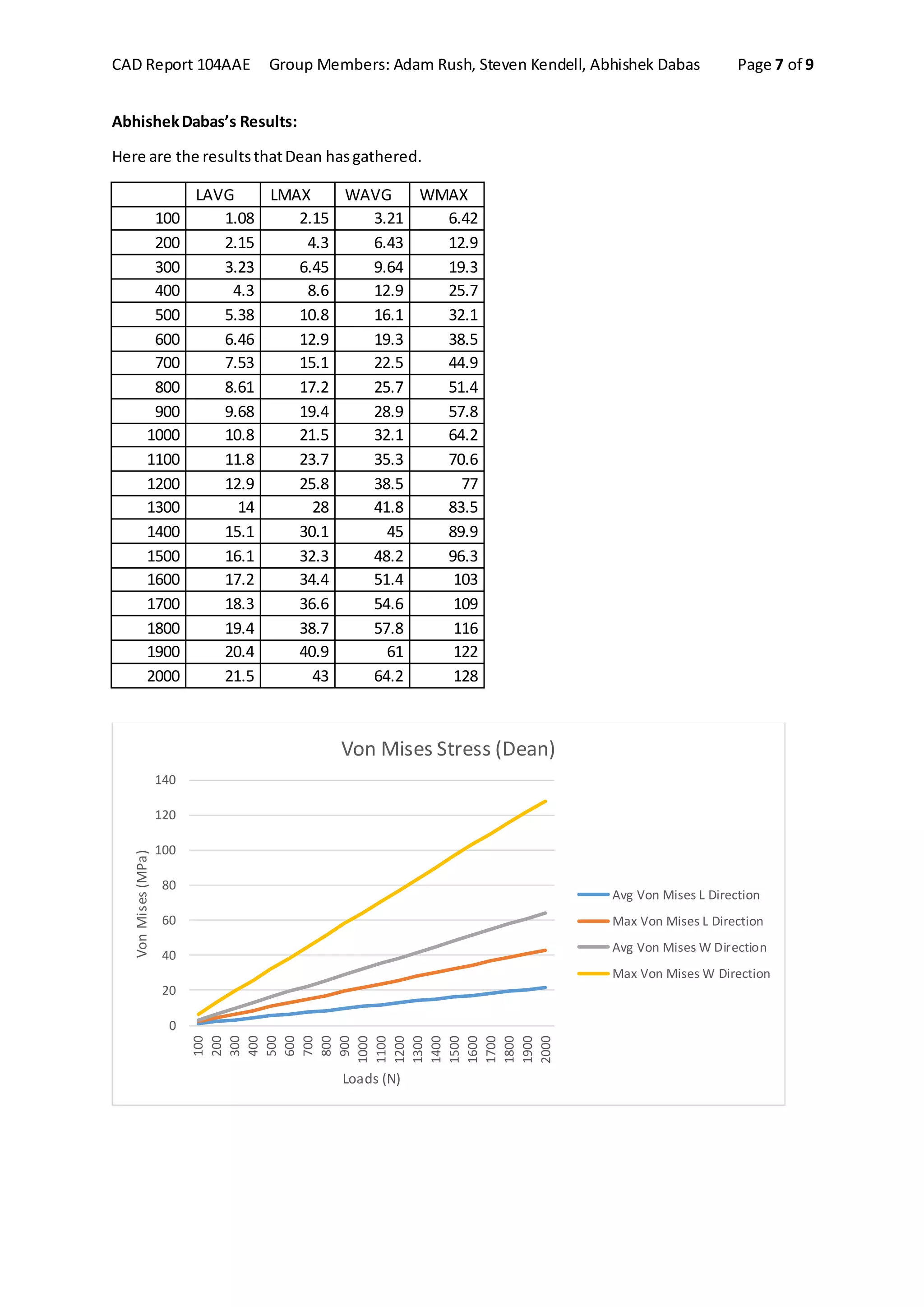

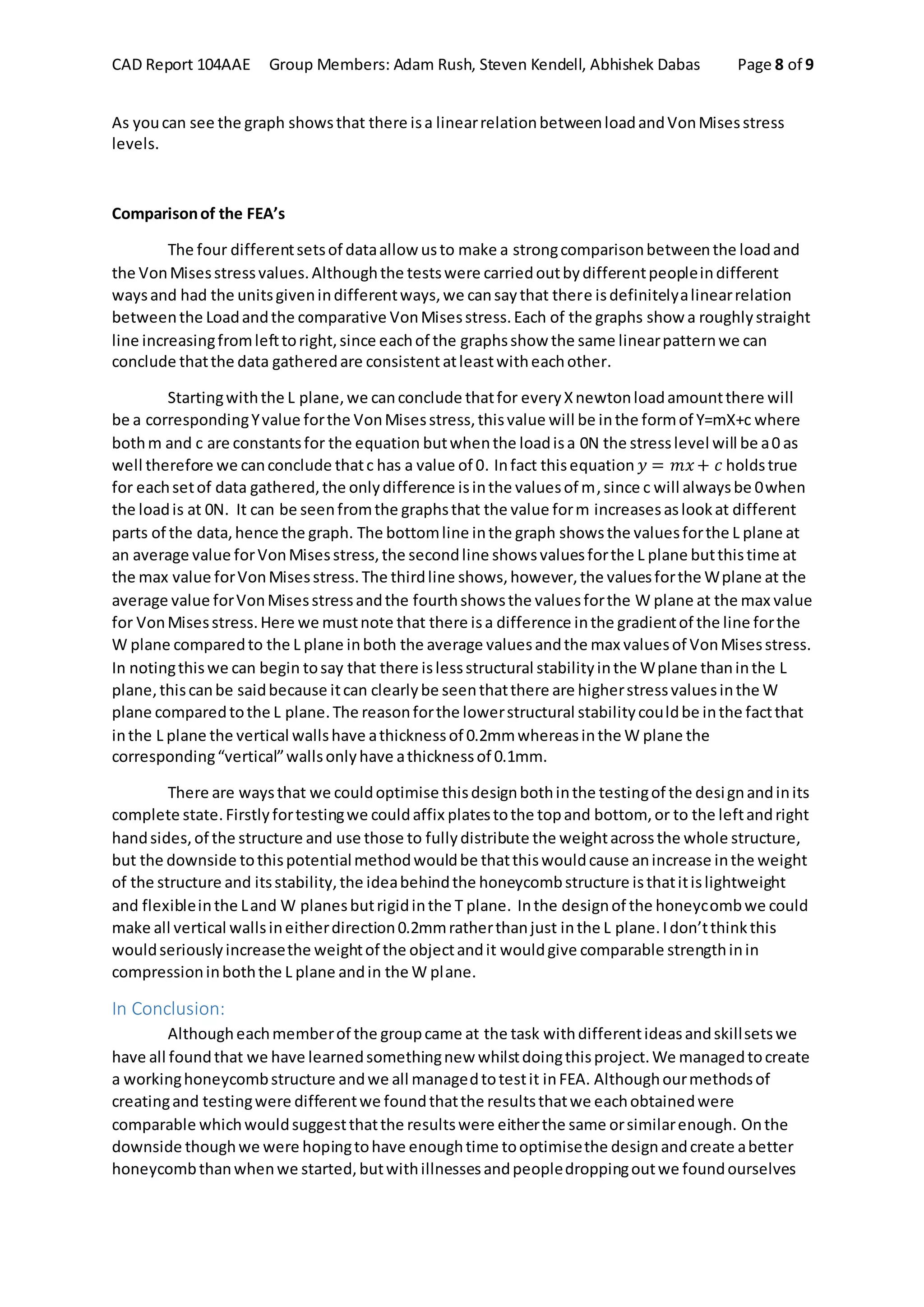

The document summarizes a CAD project completed by group members Adam Rush, Steven Kendell, and Abhishek Dabas to model and test a honeycomb structure made of aluminum 3003 using finite element analysis. Steven created the honeycomb CAD model in Catia consisting of 20 by 22 hexagonal cells. Adam and Steven then tested the model under compression loads in the L and W directions and recorded von Mises stress values. Testing showed the structure withstood 2000N of load in the L direction but failed at 1600N in the W direction. Stress levels were higher in the W direction. Additional testing compared the aluminum 3003 honeycomb to one made of aluminum 5056.