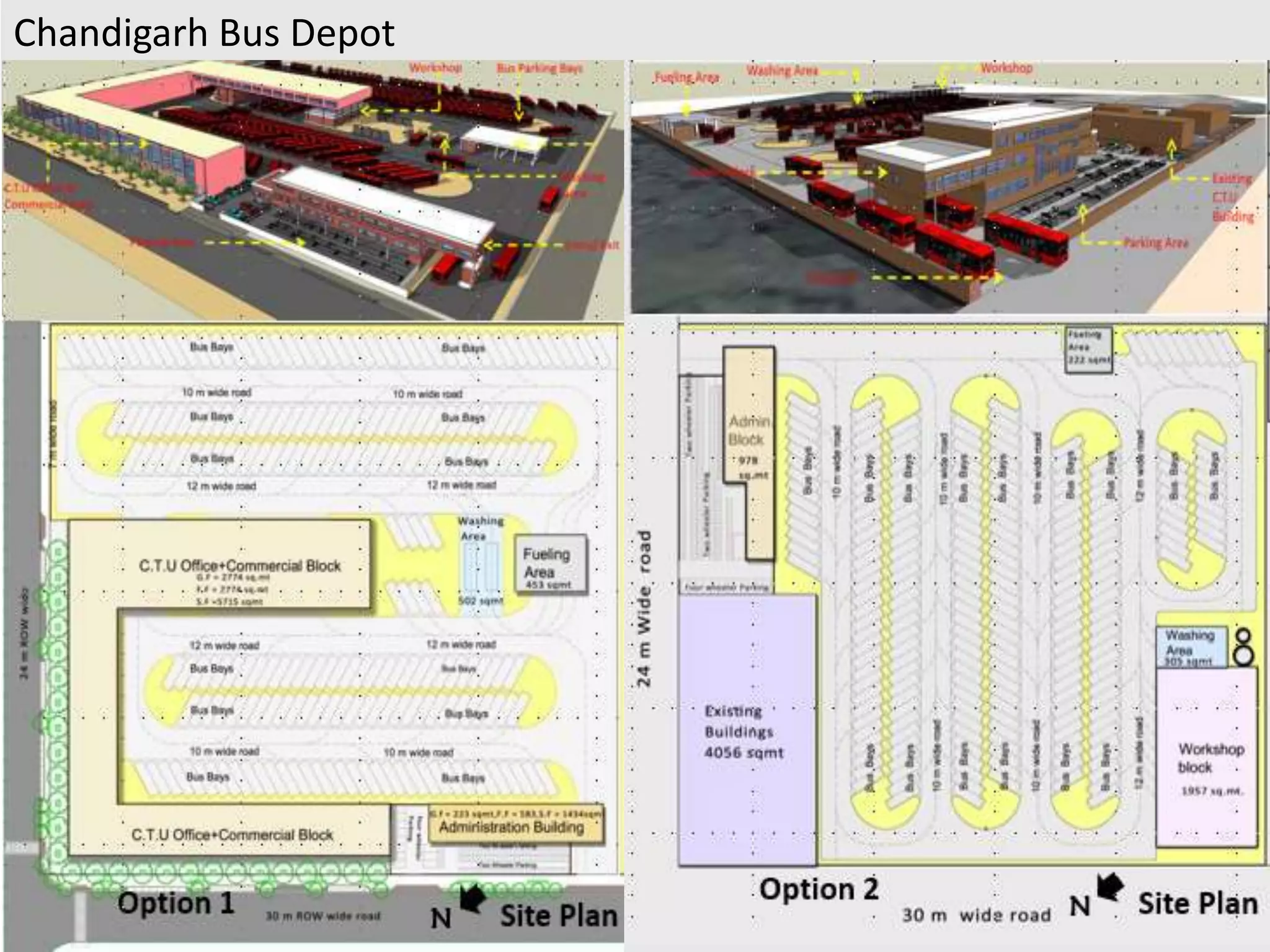

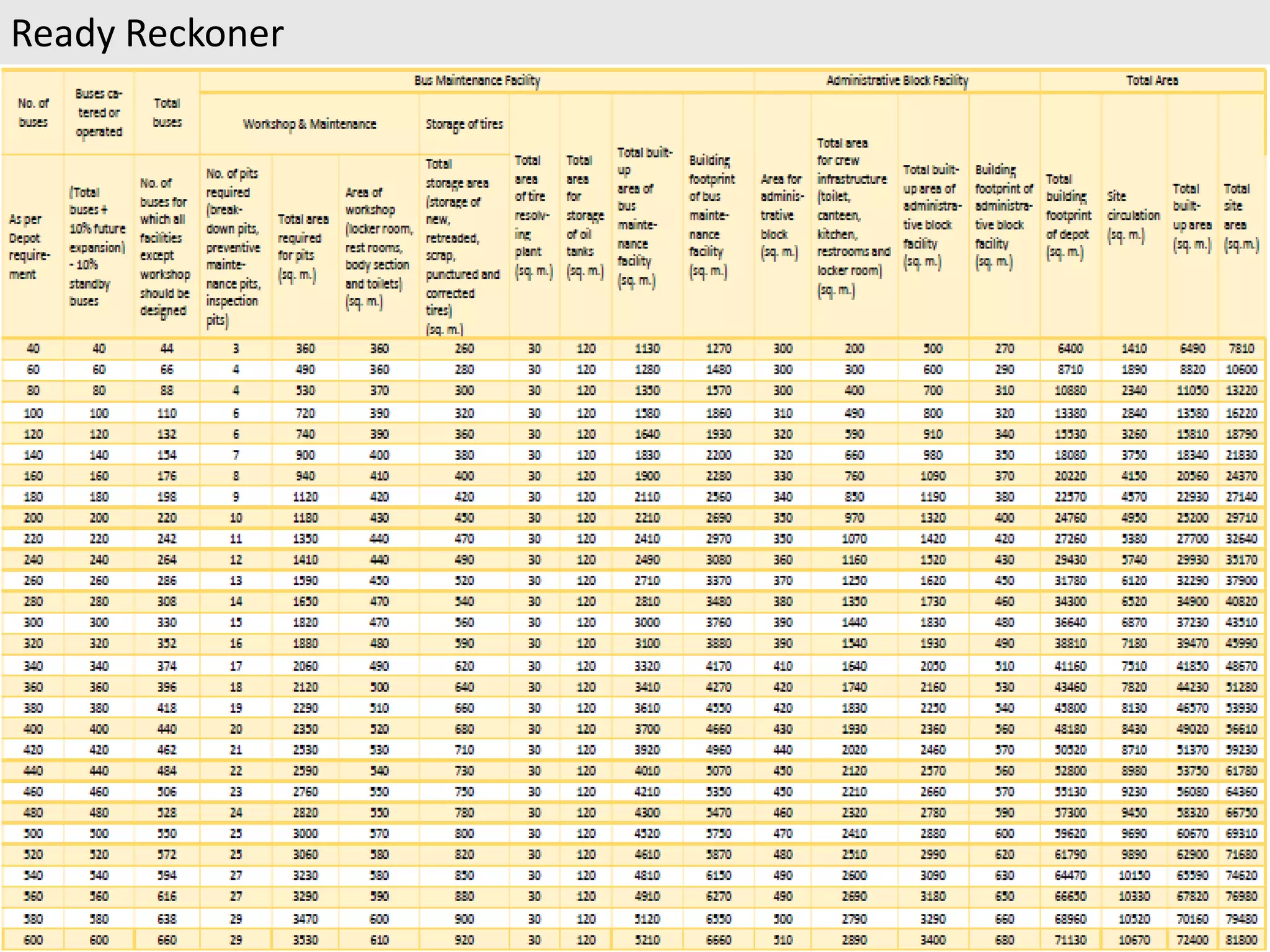

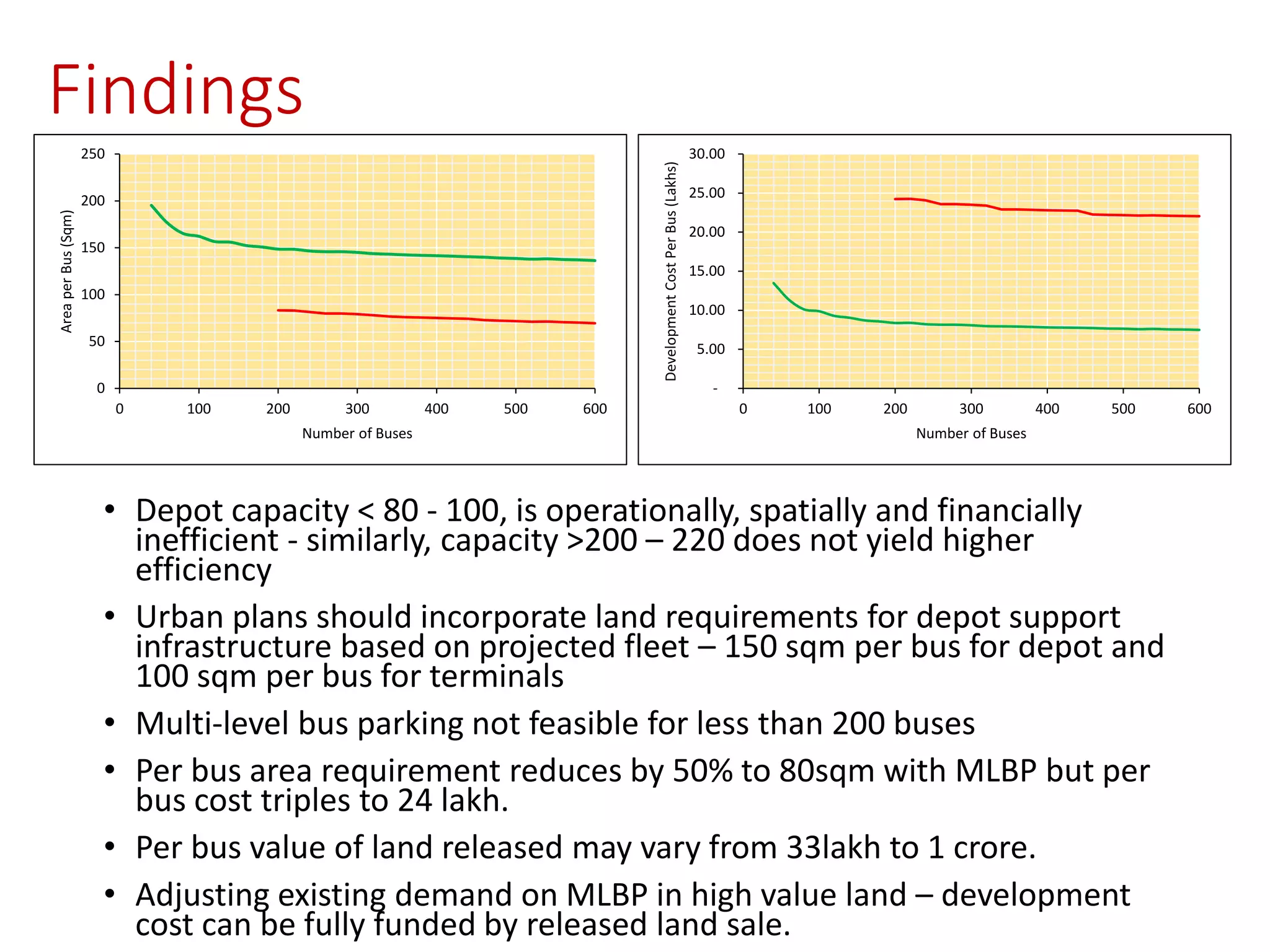

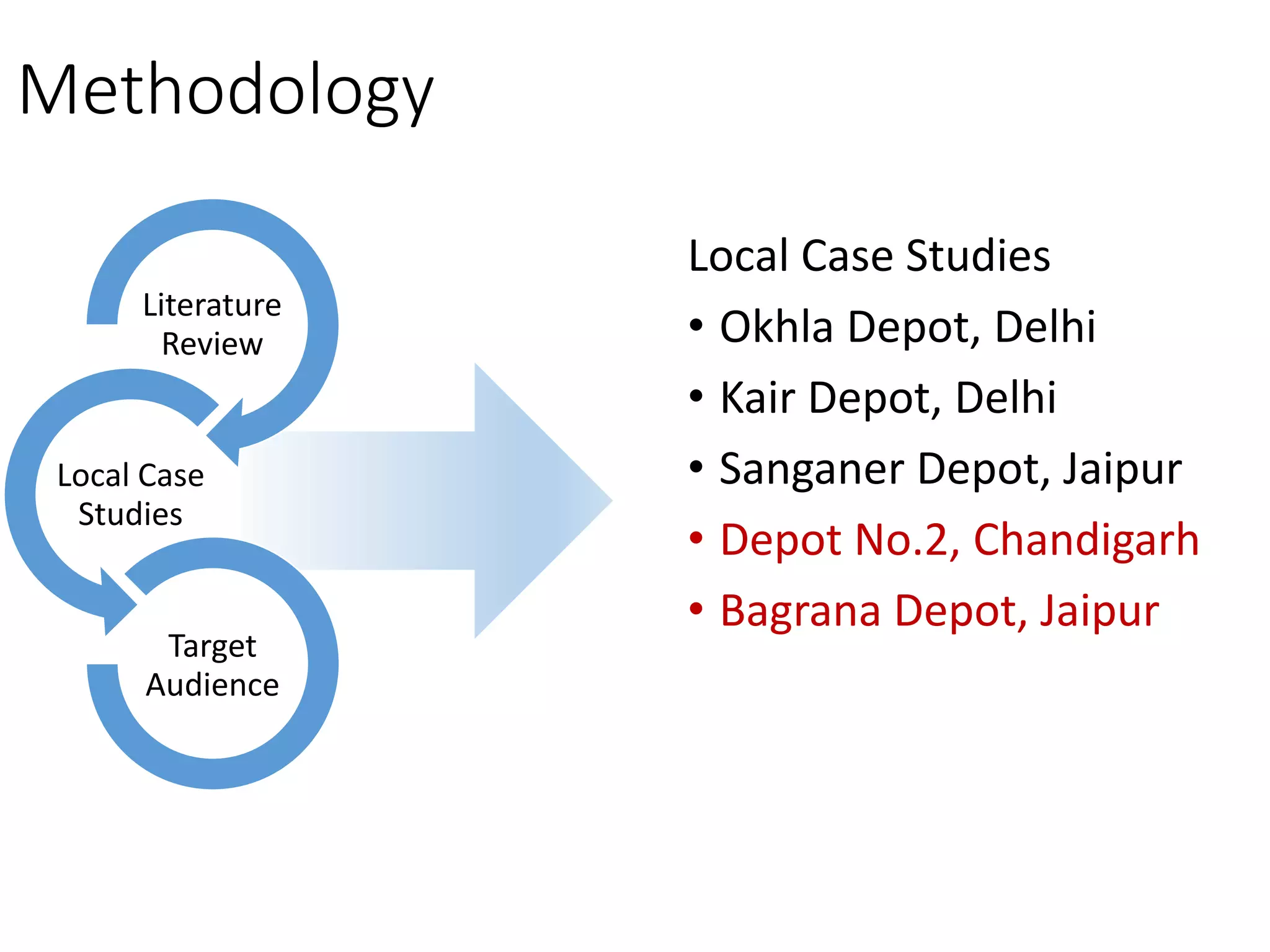

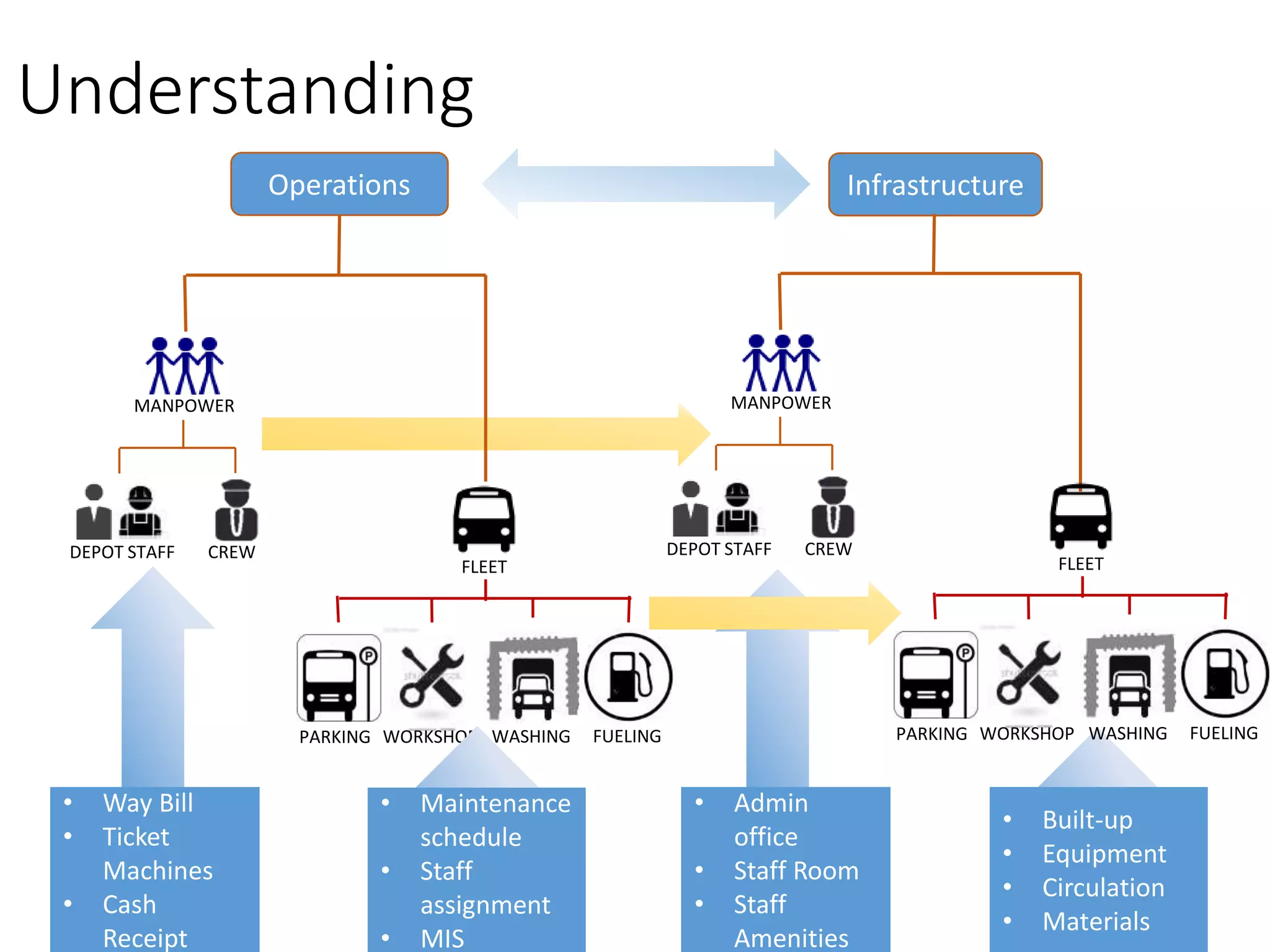

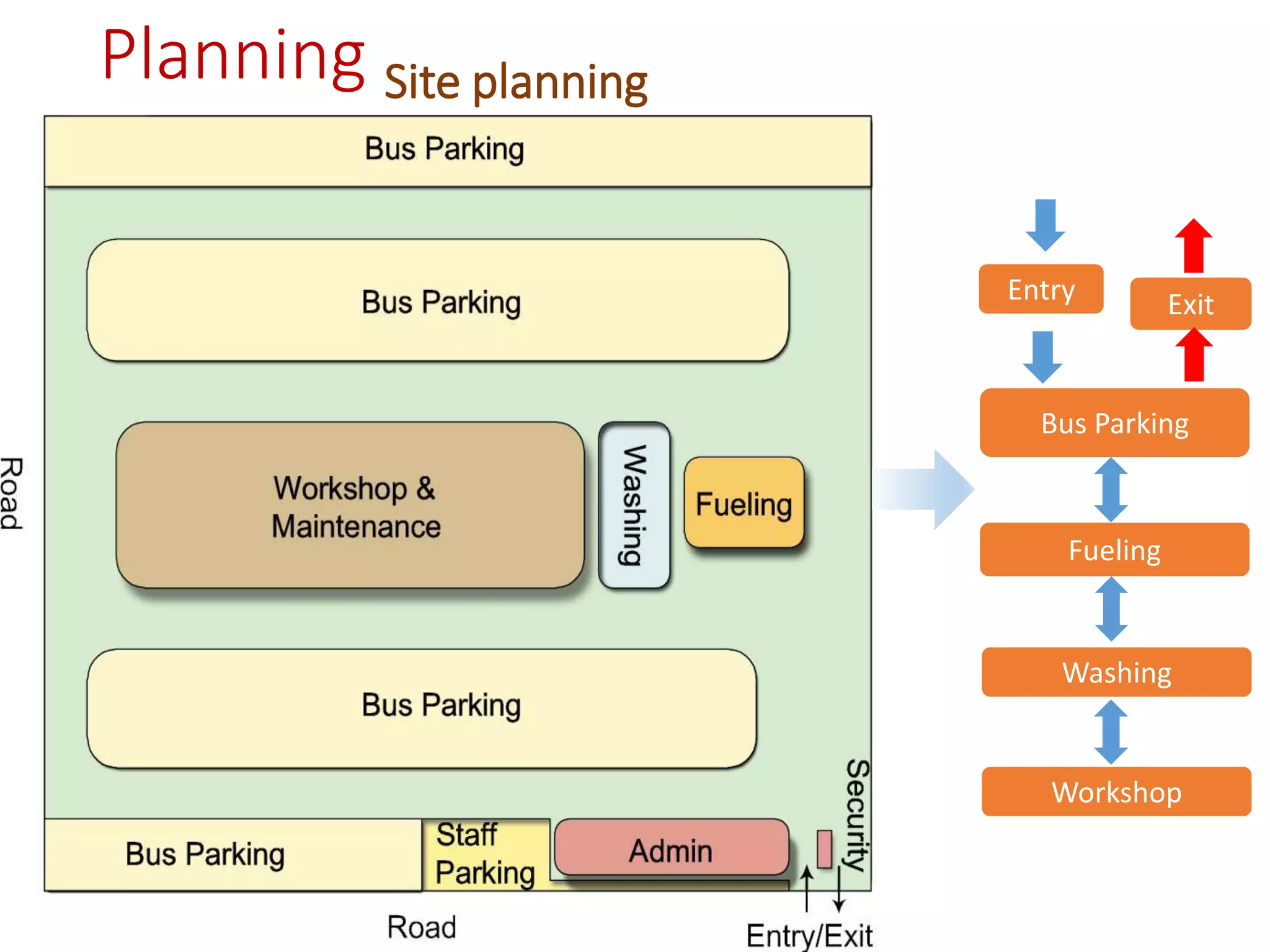

This document provides guidelines for bus depot design based on case studies of existing depots. It discusses current issues with public bus transportation like declining ridership. The guidelines aim to help state transit agencies properly plan and design bus depots. It covers topics like understanding depot operations, functional area requirements, site planning considerations, and financing models like public-private partnerships. Case studies of specific depots in cities like Delhi and Jaipur are also analyzed. Tables and diagrams are used to illustrate best practices for layout, capacity needs, and spatial requirements.

![Design Aspects Functional & Spatial Requirements

• Entry and Exit

• Parking

• Fuelling

• Washing

• Workshop

• Storage areas

Fueling area

Avg. time/bus

for fueling /

dispenser (min)

No. of buses /

hour/dispenser

Daily

working

hours

Catering

capacity/

dispenser

(for 8 hrs.) (a)

No. of

dispensers

required for

diesel buses

[per 100 buses]

(total buses/a)

5min 12 buses 8hrs 96 buses 100 / 96

= 1

Dispenser Island area 2 sq.m (2m x 1m)

[Minimum]

Other requirements for fueling area

Particulars Area

Administration Office 12 sq.m

Staff Office 15 sq.m

Toilet 9 sq.m

Storage 20 sq.m

Underground tank Capacity (100

buses)

13200 gallons

Total km/bus/day 240 km

Litre consume/day/bus 160 litre

Functional & Spatial

Requirements for Fueling

area is provided in tabular

format with diagram](https://image.slidesharecdn.com/sgarchitectsbusdepotdesignguidelinetalkingtransitnov20162-161121153704/75/Bus-Karo-Bus-Depot-Design-Guideline-11-2048.jpg)