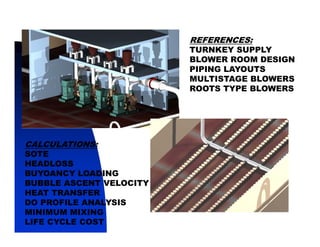

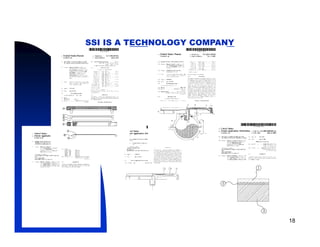

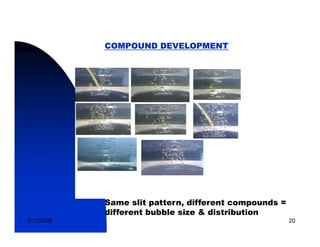

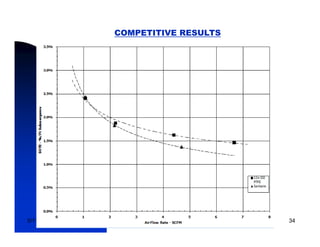

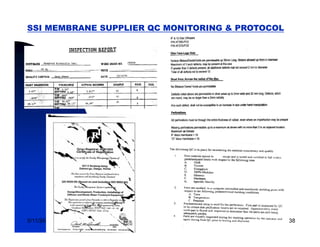

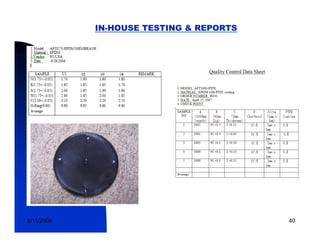

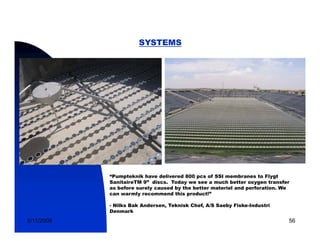

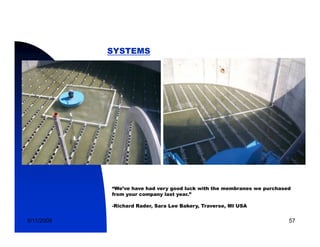

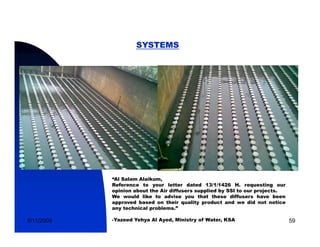

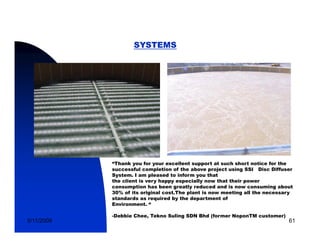

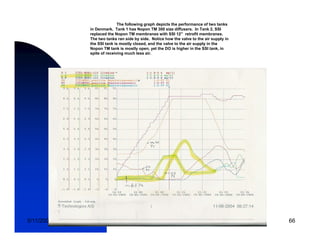

The document outlines the advantages of using innovative aeration technologies from SSI, highlighting their patent-pending PTFE-coated membrane diffusers that significantly outperform traditional EPDM membranes in terms of fouling resistance and longevity. It discusses the cost benefits of reduced maintenance and replacement cycles, as well as testimonials from satisfied customers. SSI's commitment to research and development is emphasized, alongside their technological expertise in designing complete aeration systems.