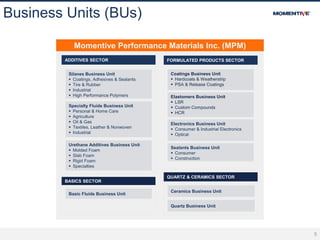

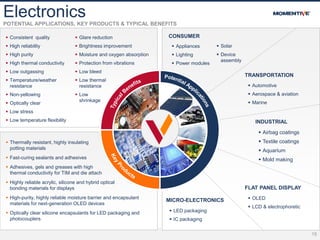

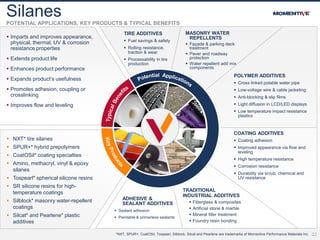

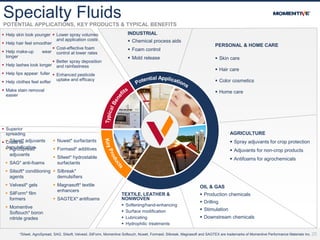

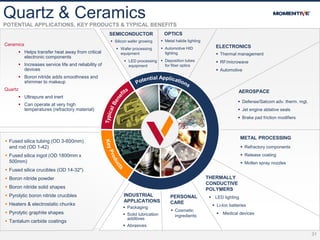

Momentive Performance Materials Inc. is an industry leader in silicone innovation with a historical legacy spanning over 70 years, having introduced numerous firsts in silicone applications across various sectors. The company operates five business units, including elastomers, electronics, coatings, and specialty fluids, serving a diverse global clientele with innovative and environmentally sound solutions. Their extensive product portfolio caters to industries such as automotive, healthcare, consumer electronics, and agriculture, ensuring high performance and reliability.