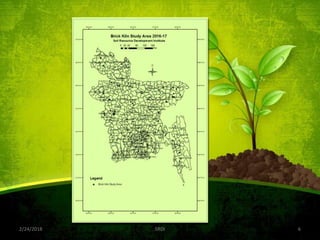

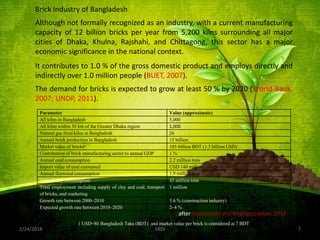

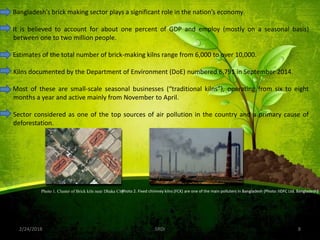

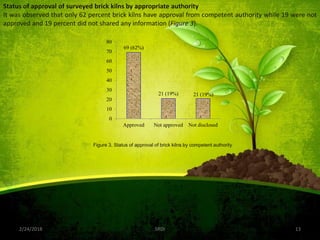

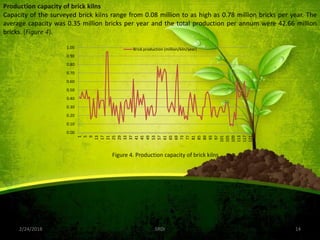

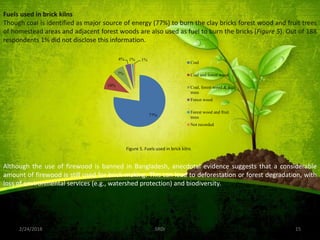

The document discusses the environmental and agricultural impacts of brick kiln operations in Bangladesh, highlighting their negative effects on soil degradation, air quality, and crop yields. It notes that brick kilns contribute significantly to the national economy but are largely unregulated, leading to severe ecological consequences. The study aims to assess the current state of brick kilns and recommend measures for sustainable practices, including stricter regulations and the use of alternative materials.