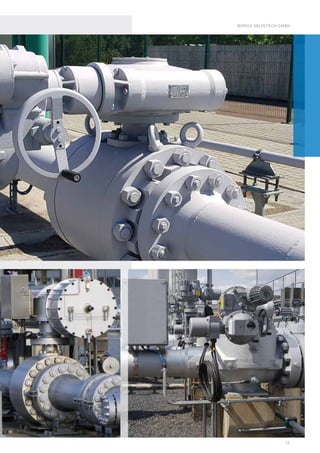

Borsig ValveTech GmbH designs and manufactures high-pressure control valves, shut-off valves, compressor valves and parts for extreme operating conditions. It offers a comprehensive range of ball valves, control valves, isolation valves, compressor parts and valve services. The company specializes in valves for gas compressor and storage stations using customized materials to achieve optimal performance under high pressures and temperatures.