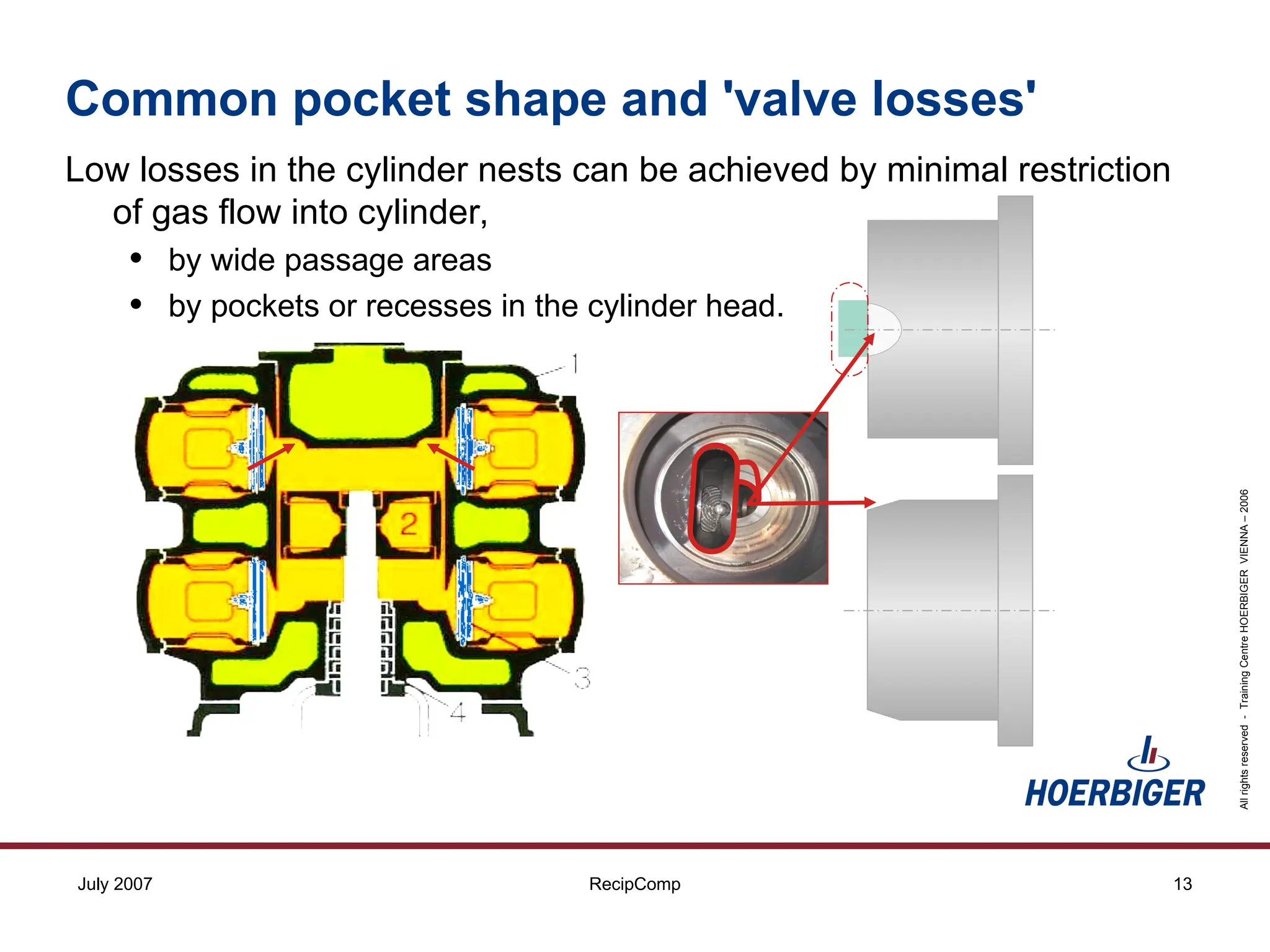

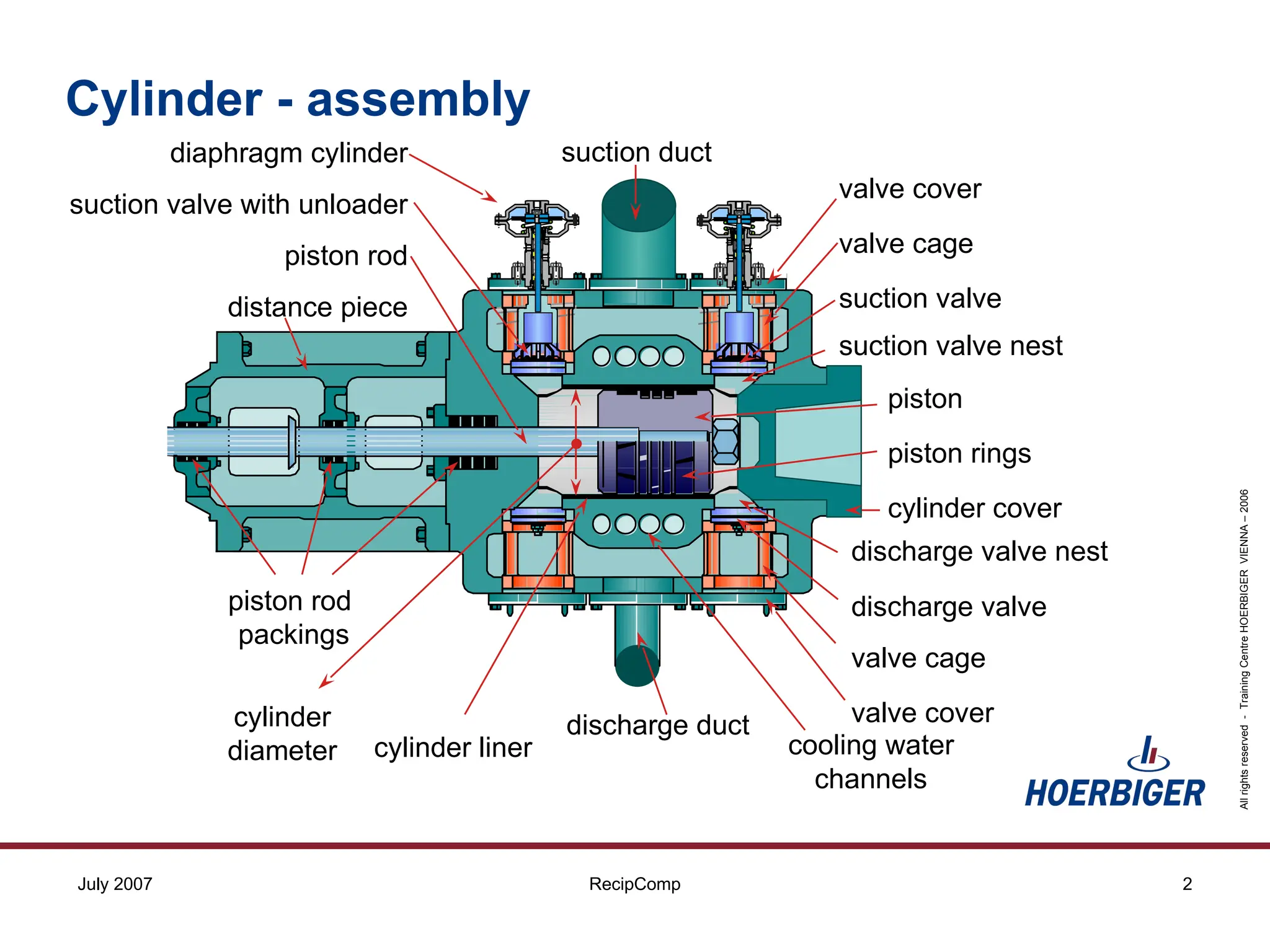

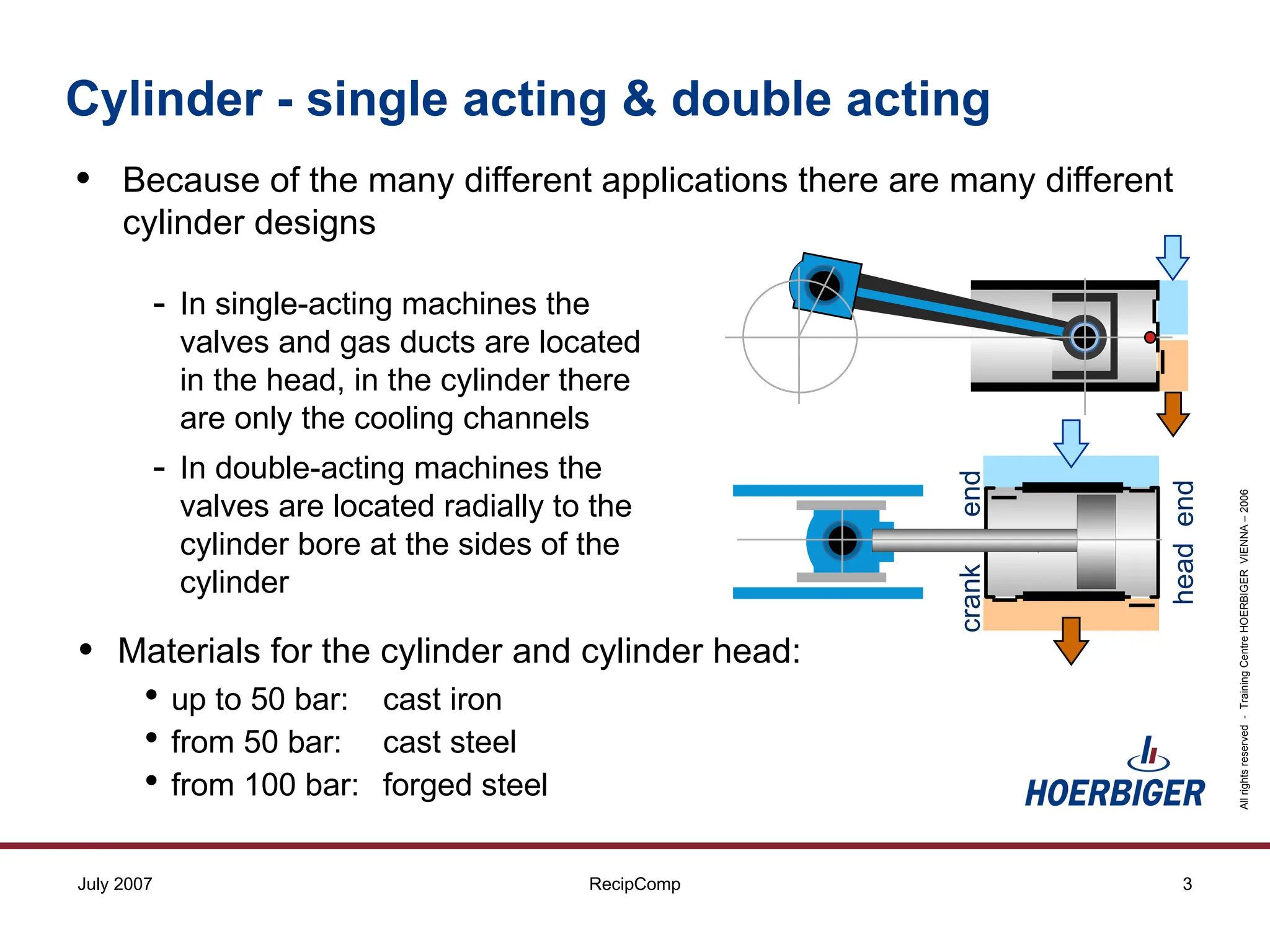

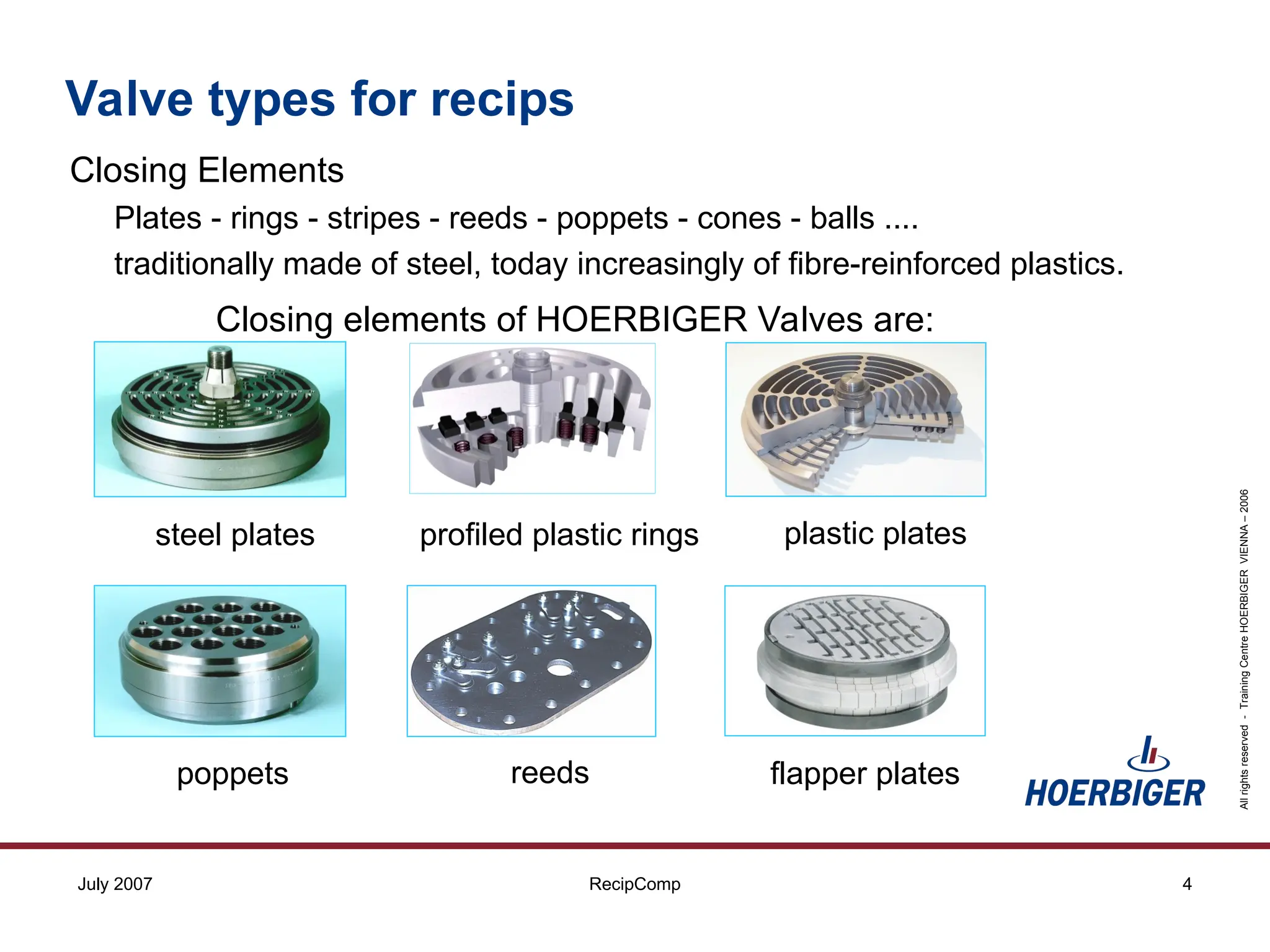

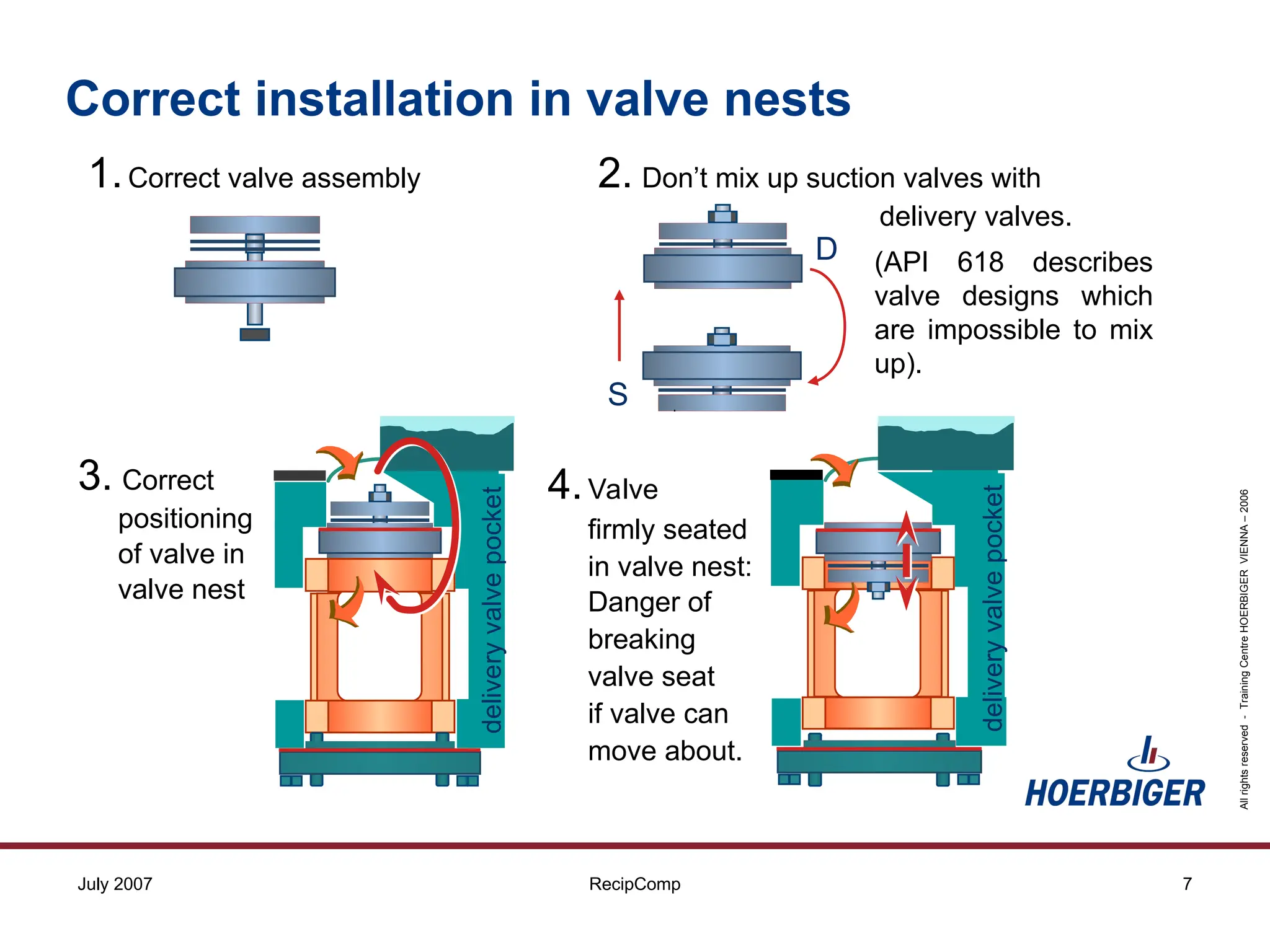

The document discusses the design and functionality of reciprocating compressor valves, highlighting key components such as the cylinder design, valve types, and material specifications. It emphasizes the importance of proper valve installation to avoid issues like gas flow losses and valve seat damage. Additionally, it outlines the impact of valve nest shape on gas flow efficiency and the potential consequences of incorrect assembly.

![All

rights

reserved

-

Training

Centre

HOERBIGER

VIENNA

–

2006

10

RecipComp

July 2007

displacement [%]

0

5

10

15

20

25

30

0% 20% 40% 60% 80% 100%

pressure

[bar]

Area bordered

by the red line:

Indicated work

of cylinder end

suction

pressure

discharge

pressure

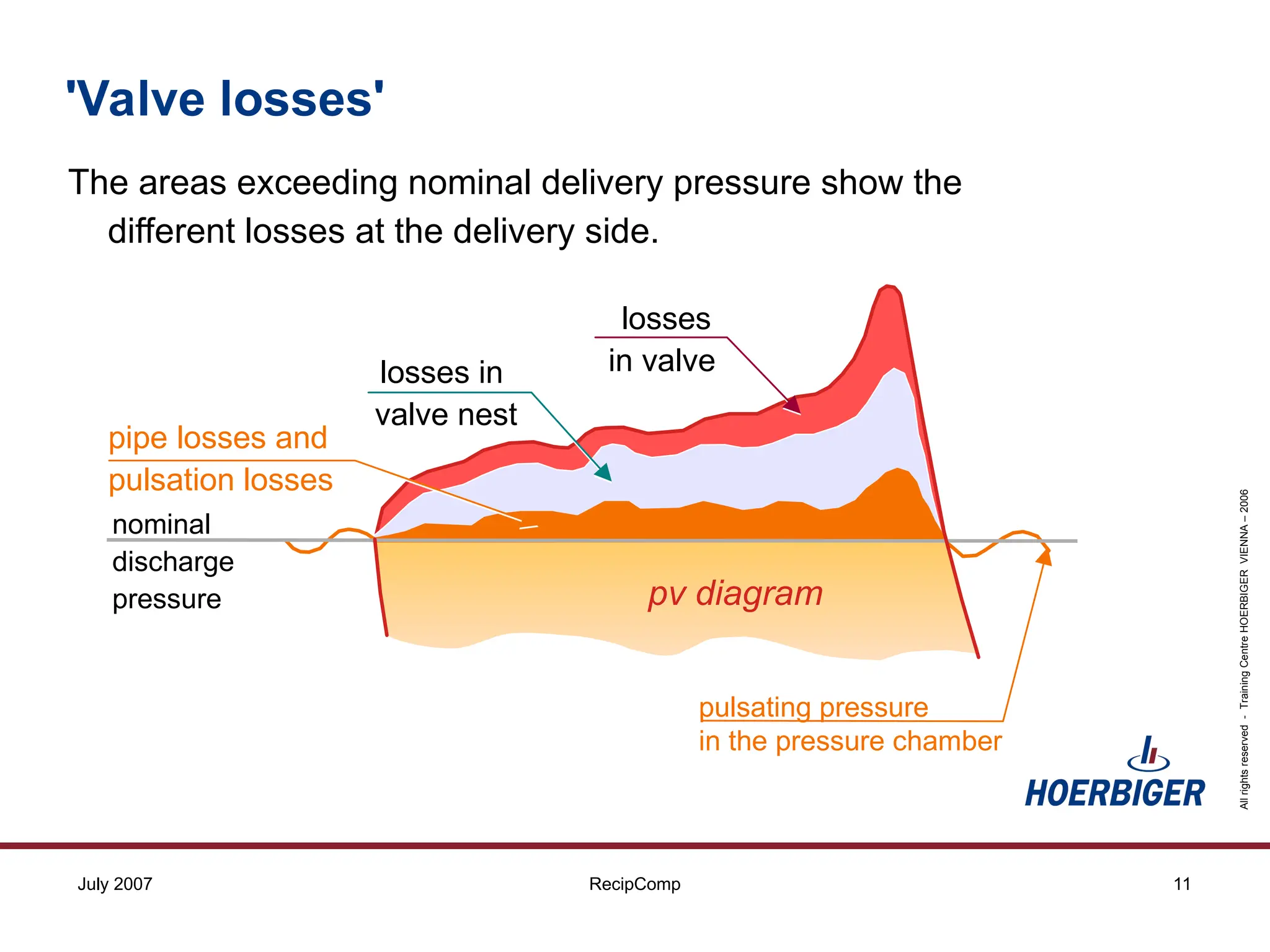

A certain percentage of the indicated power is lost due to:

Discharge losses

Total Gas Flow Losses in Indicator Diagram

'Valve losses'

Suction losses](https://image.slidesharecdn.com/valvetype-recipcompigl-241013171603-a150dc2d/75/Reciprocating-Compressor-Cylinder-Valves-10-2048.jpg)