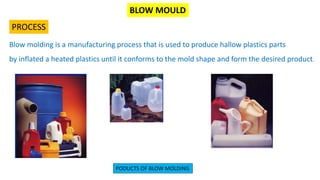

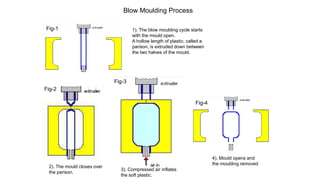

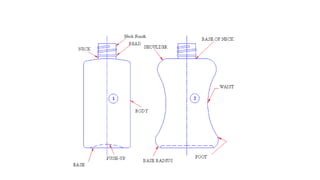

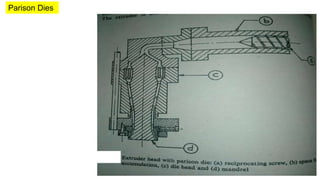

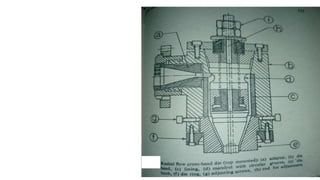

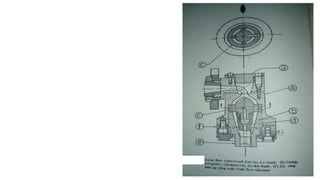

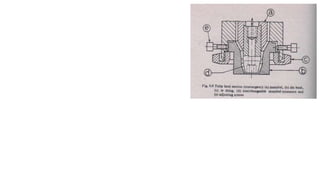

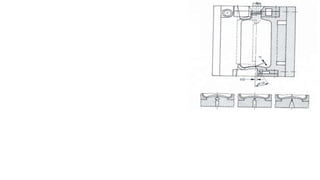

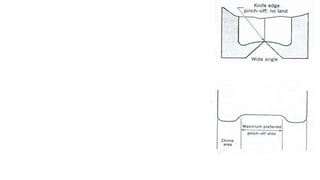

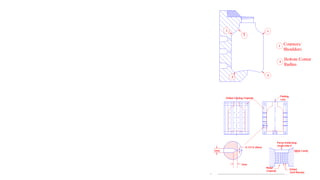

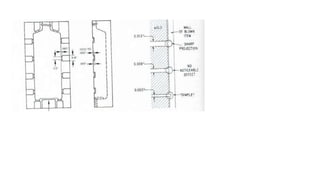

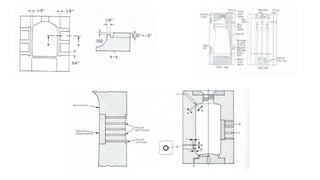

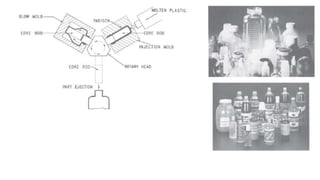

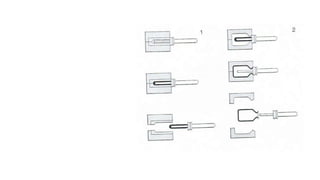

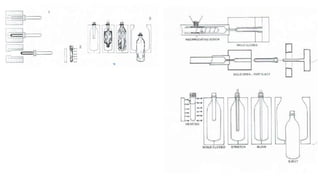

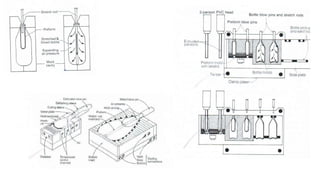

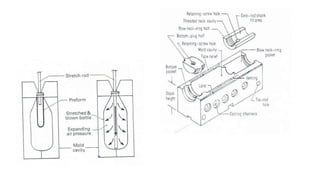

Blow molding is a manufacturing process that uses compressed air to inflate heated plastic against a mold to form hollow plastic parts. Products made through blow molding include packaging for foods, liquids, and medicines, as well as automotive fuel tanks, toys, and household items. The blow molding process involves extruding a hollow plastic tube called a parison, closing the mold around the parison, and inflating the soft plastic with compressed air to take the shape of the mold cavity before opening the mold. Design considerations for blow molded parts include the material, size, contours, texture, edges and corners of the part.