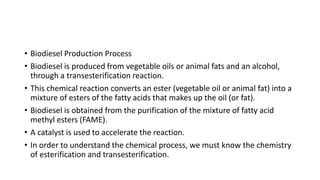

Biodiesel is a renewable biofuel derived from vegetable oils or animal fats, used in diesel engines, and defined by ASTM as a mixture of monoalkyl esters. It can significantly reduce harmful emissions compared to petroleum diesel and is produced through transesterification using raw materials like rapeseed and soybean oils, along with alcohols such as methanol or ethanol. The production process emphasizes economic viability and large-scale production without competing for food resources.