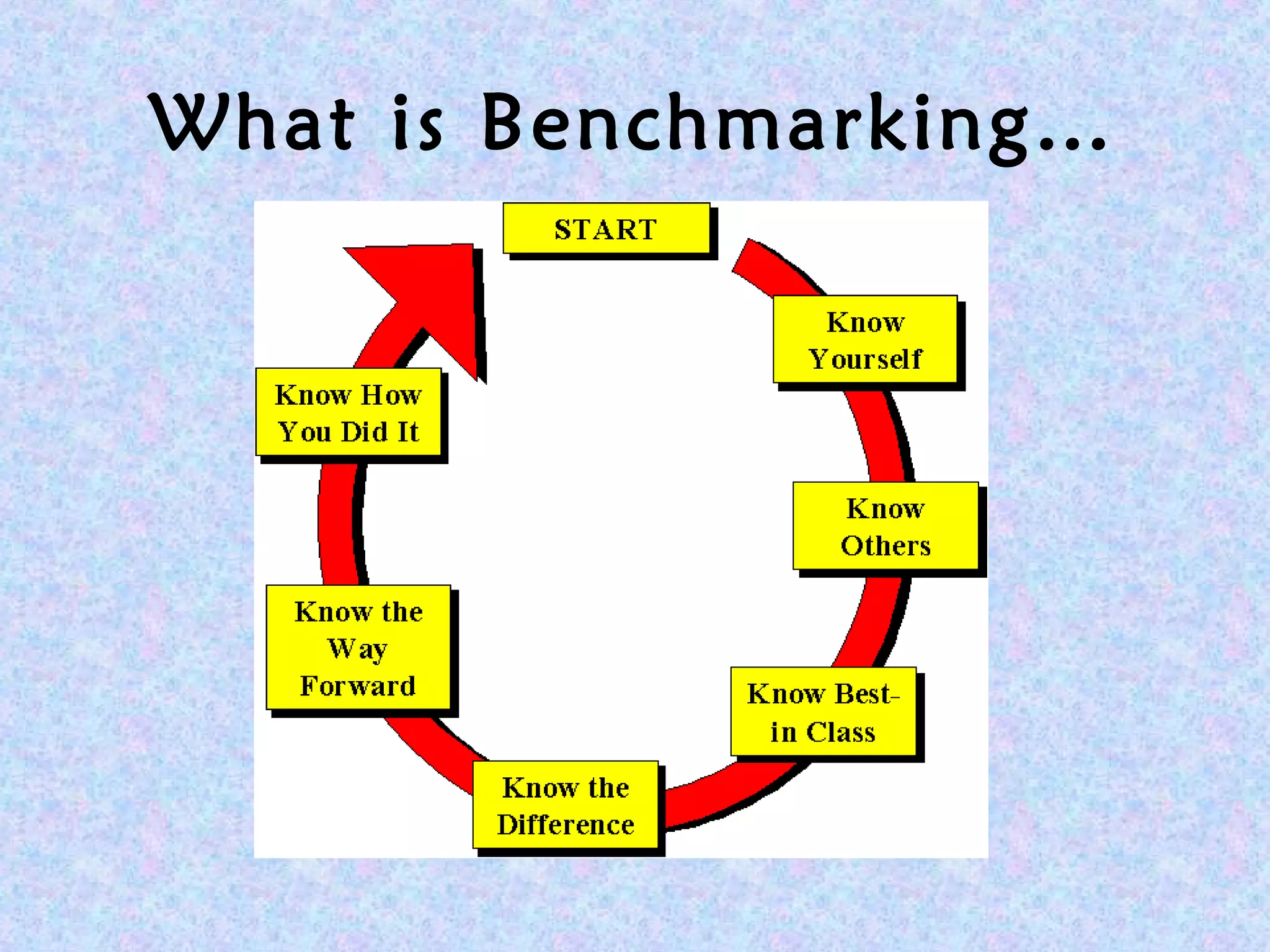

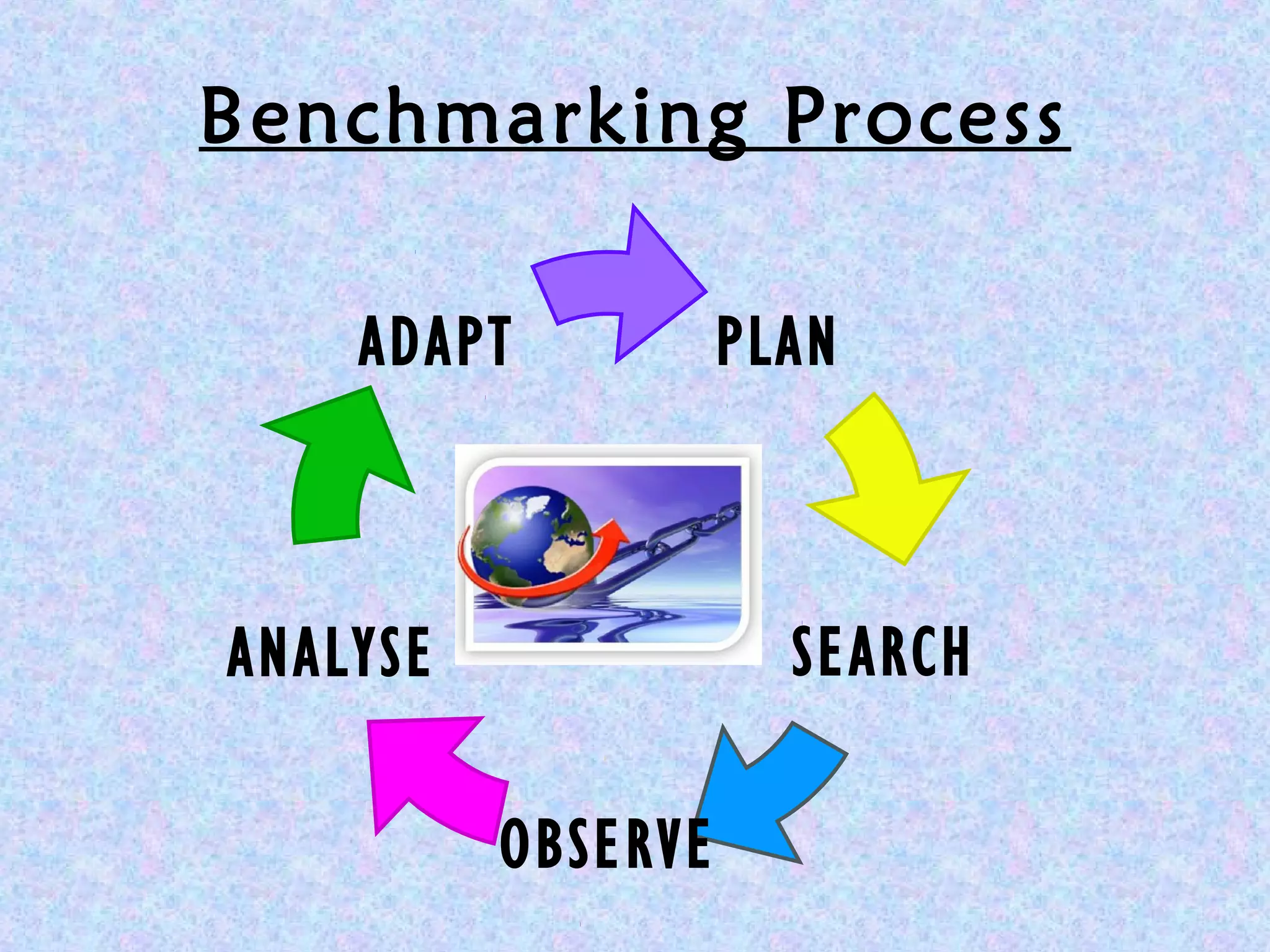

Benchmarking is the process of comparing business processes and performance metrics to other organizations considered best practices. It involves identifying top performance of other companies and using it as a standard to improve one's own performance. There are different types of benchmarking including internal, competitive, and external benchmarking. The benchmarking process involves planning, searching for benchmark partners, observing their processes, analyzing data to identify performance gaps, and adapting improvements. Benchmarking helps improve performance but requires significant resources and companies may be reluctant to share information.