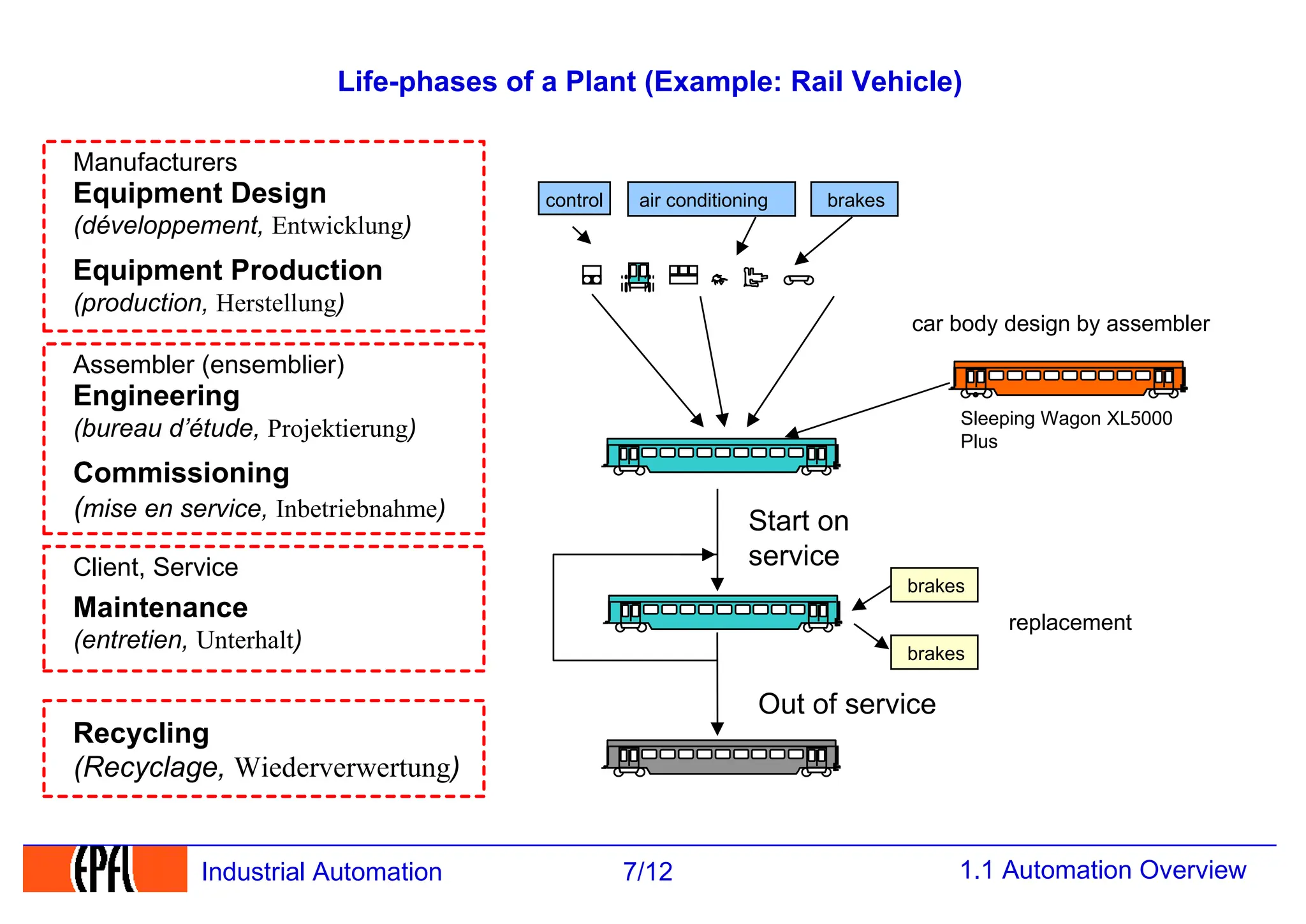

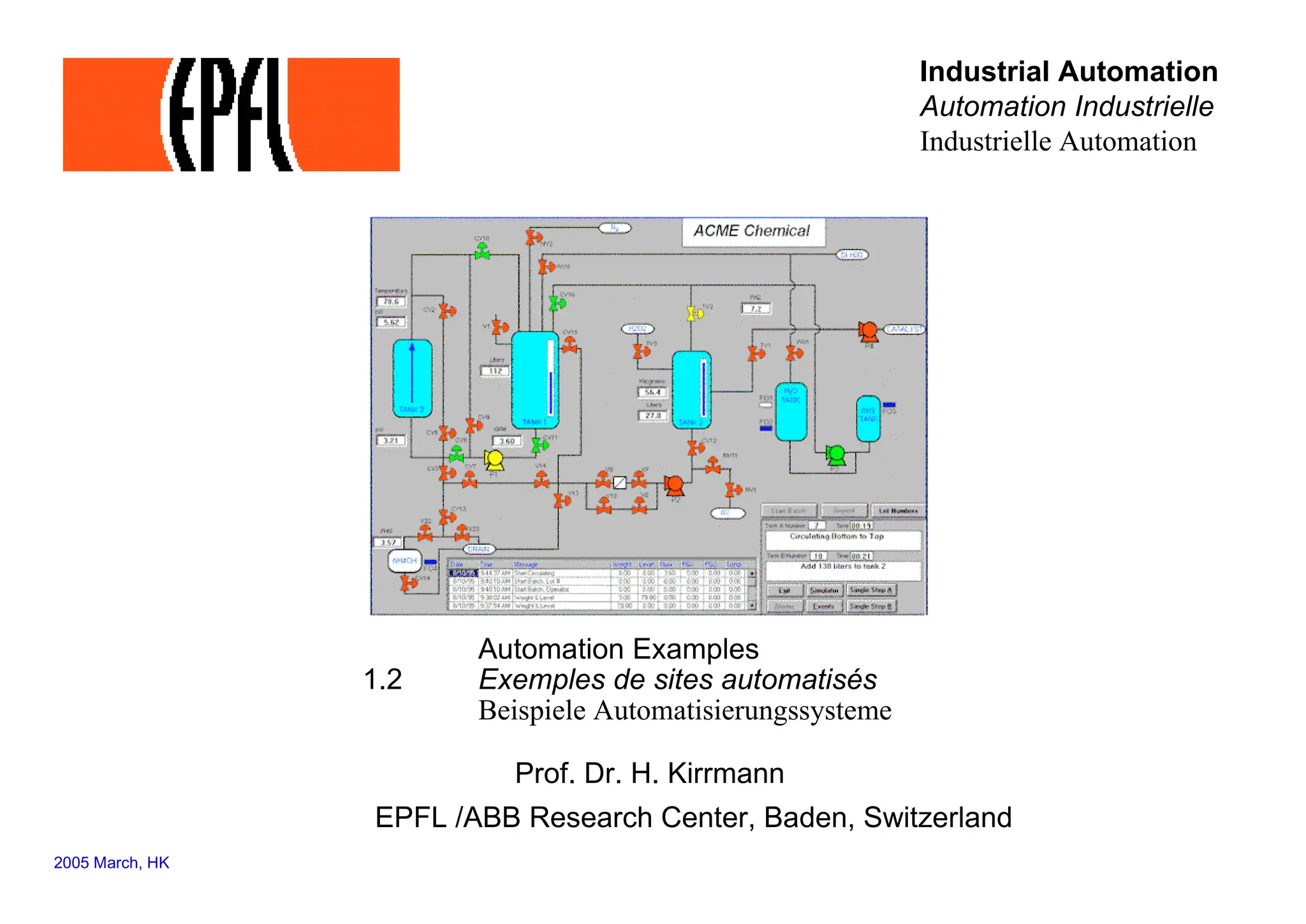

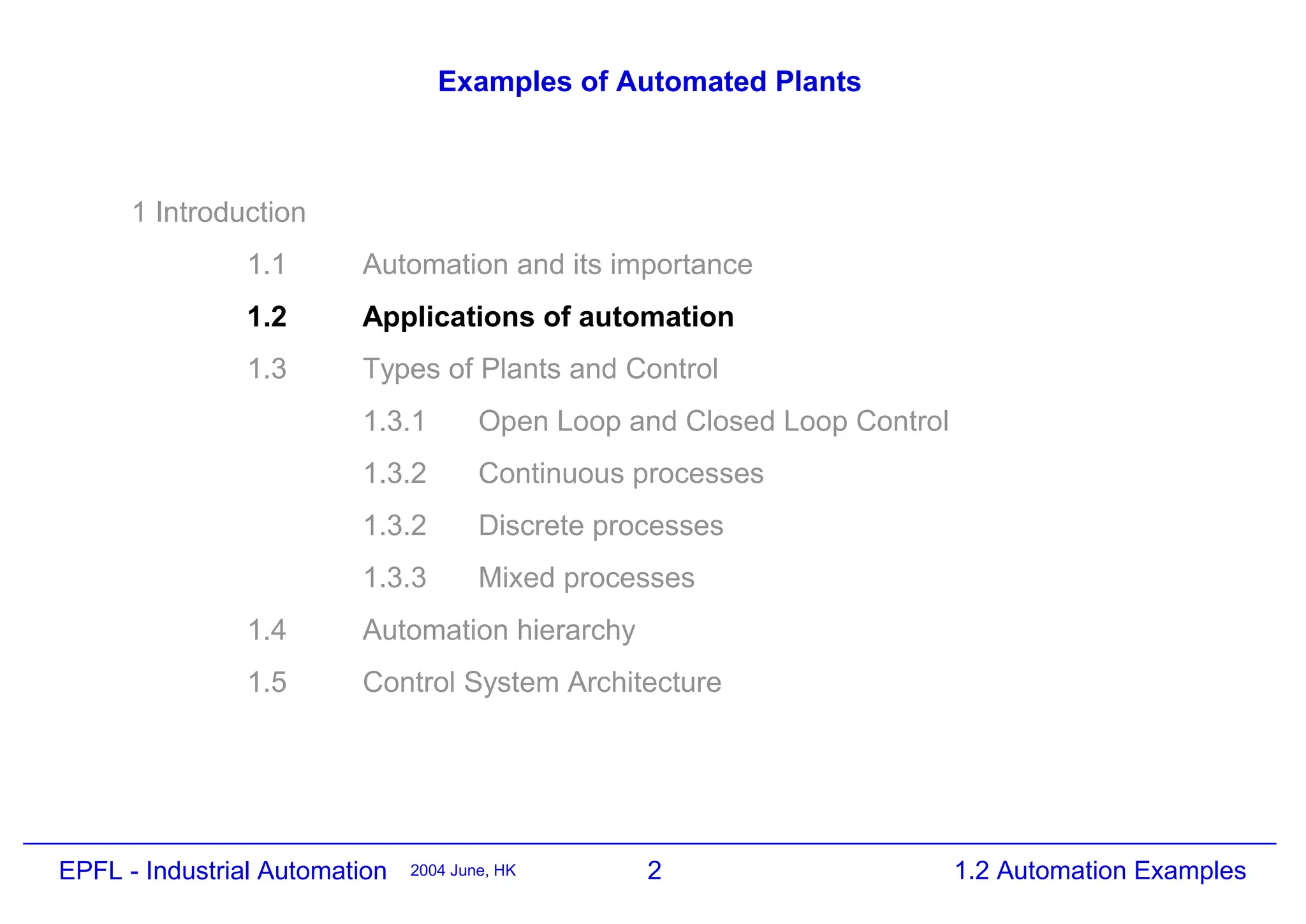

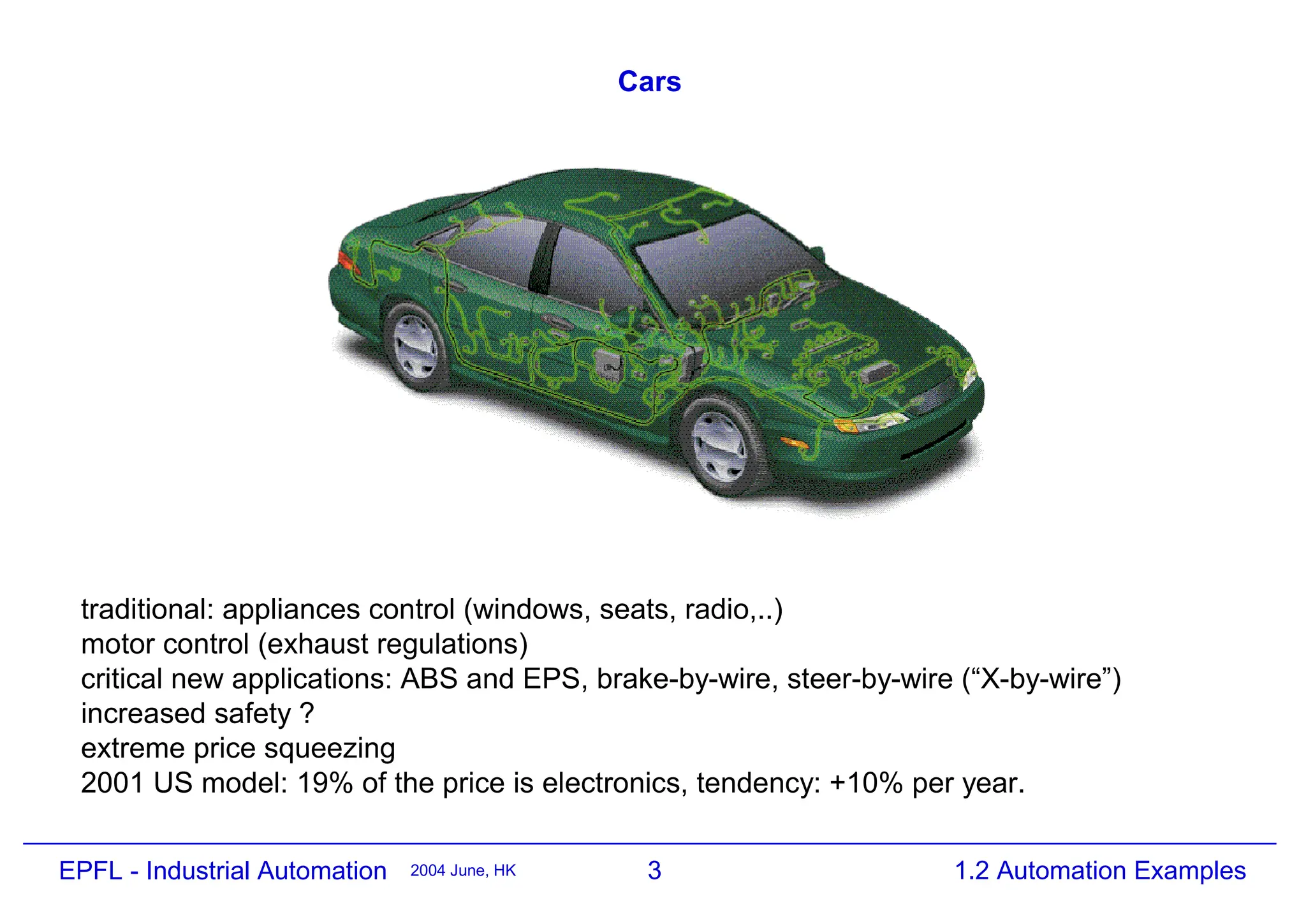

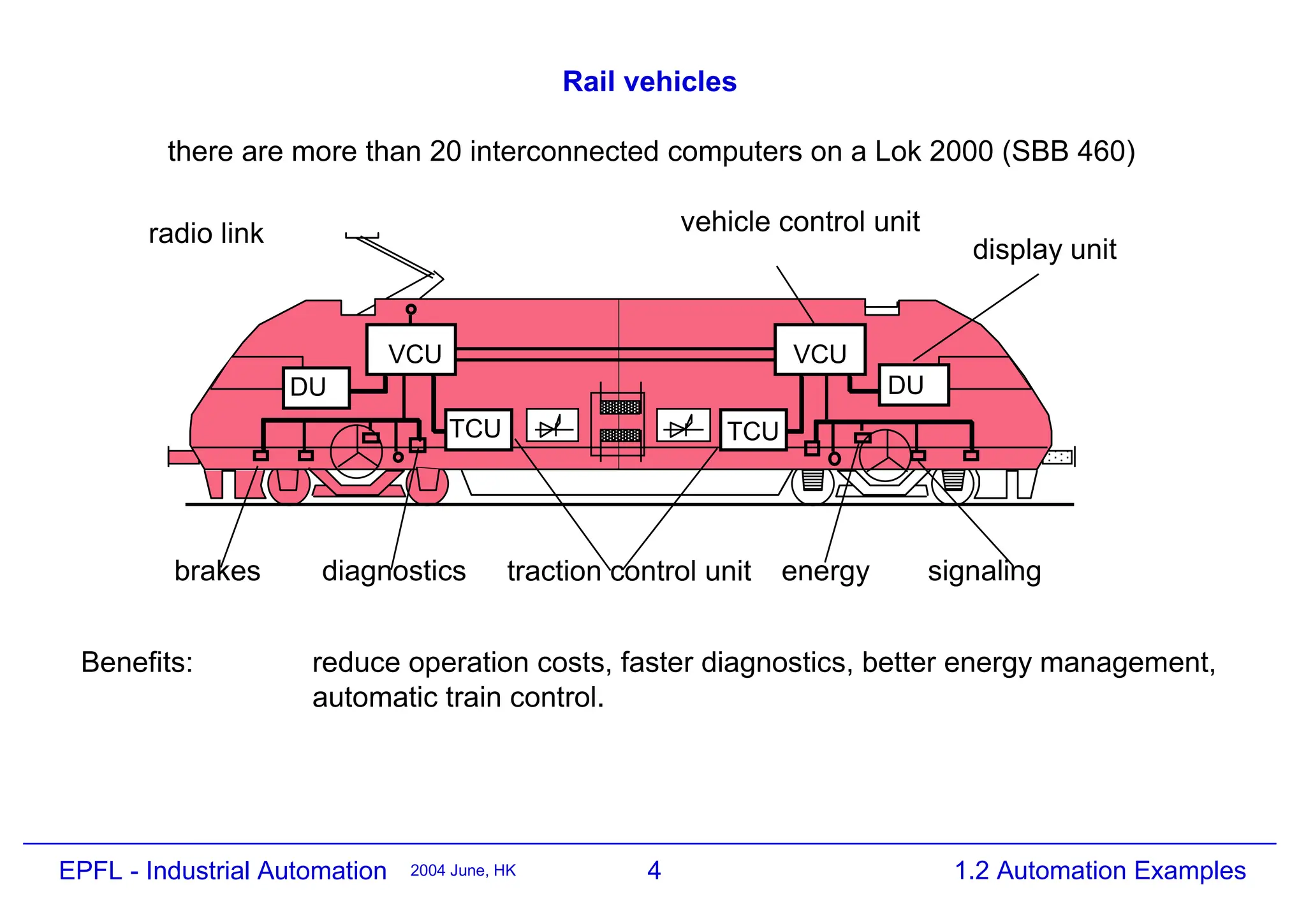

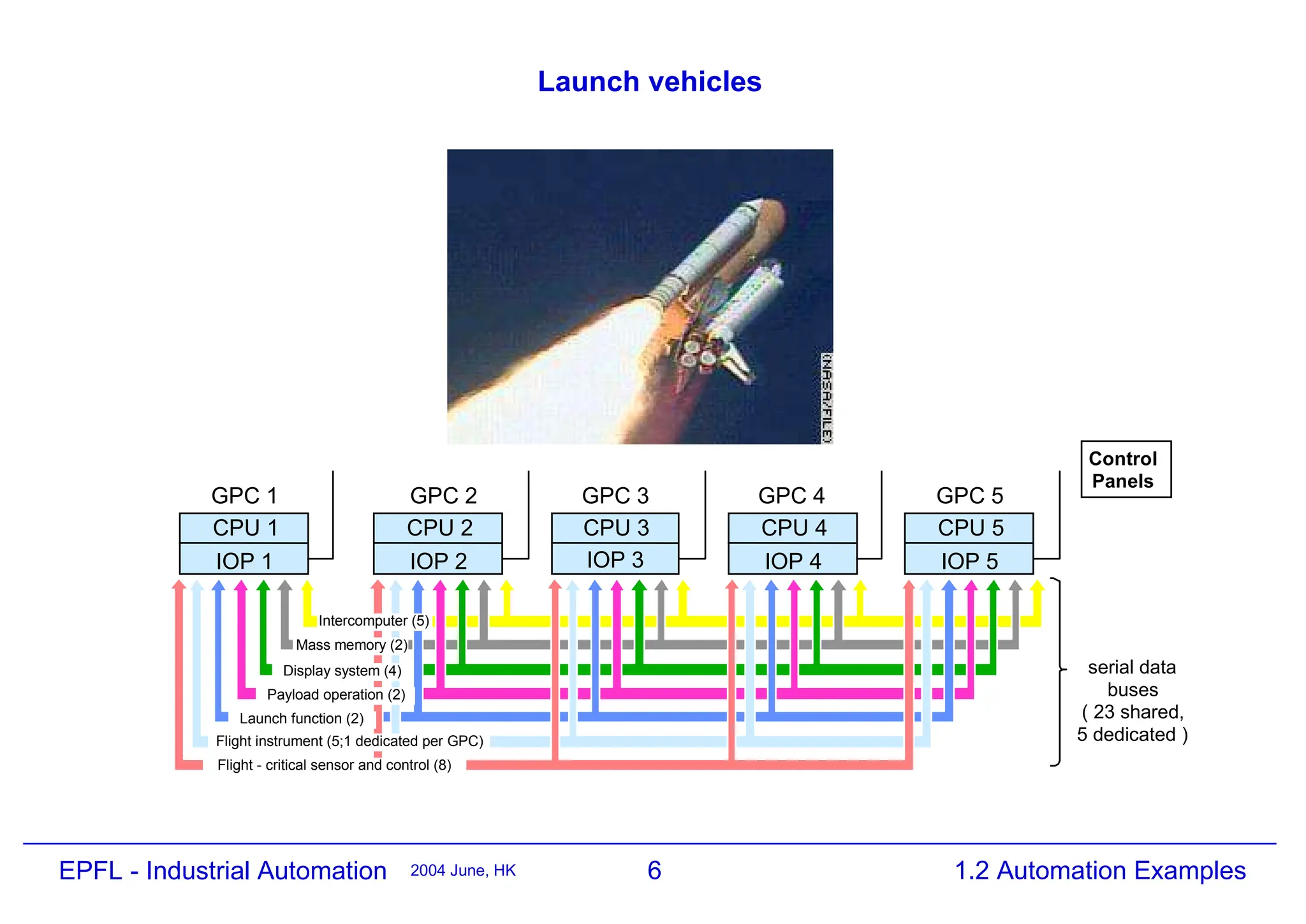

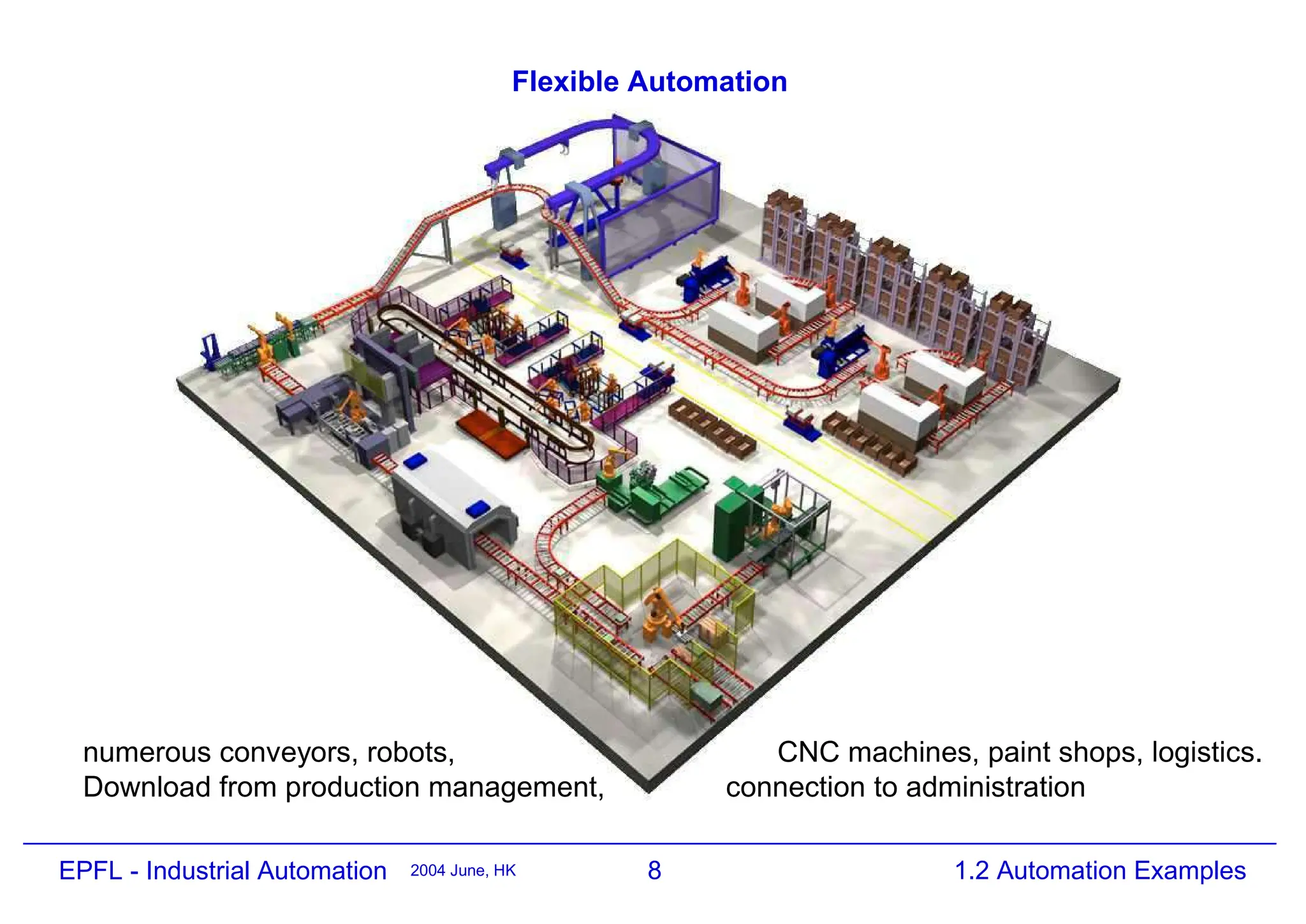

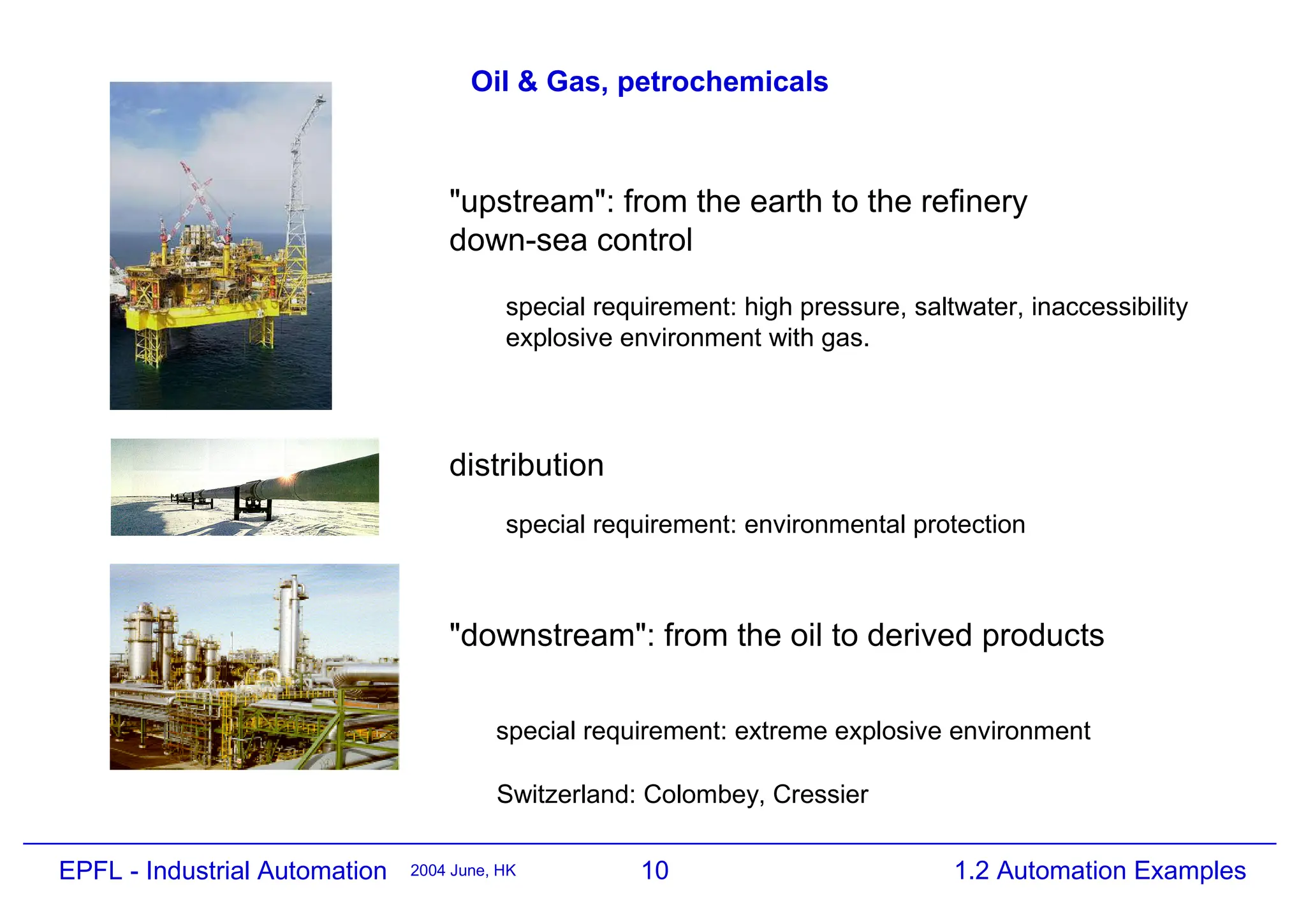

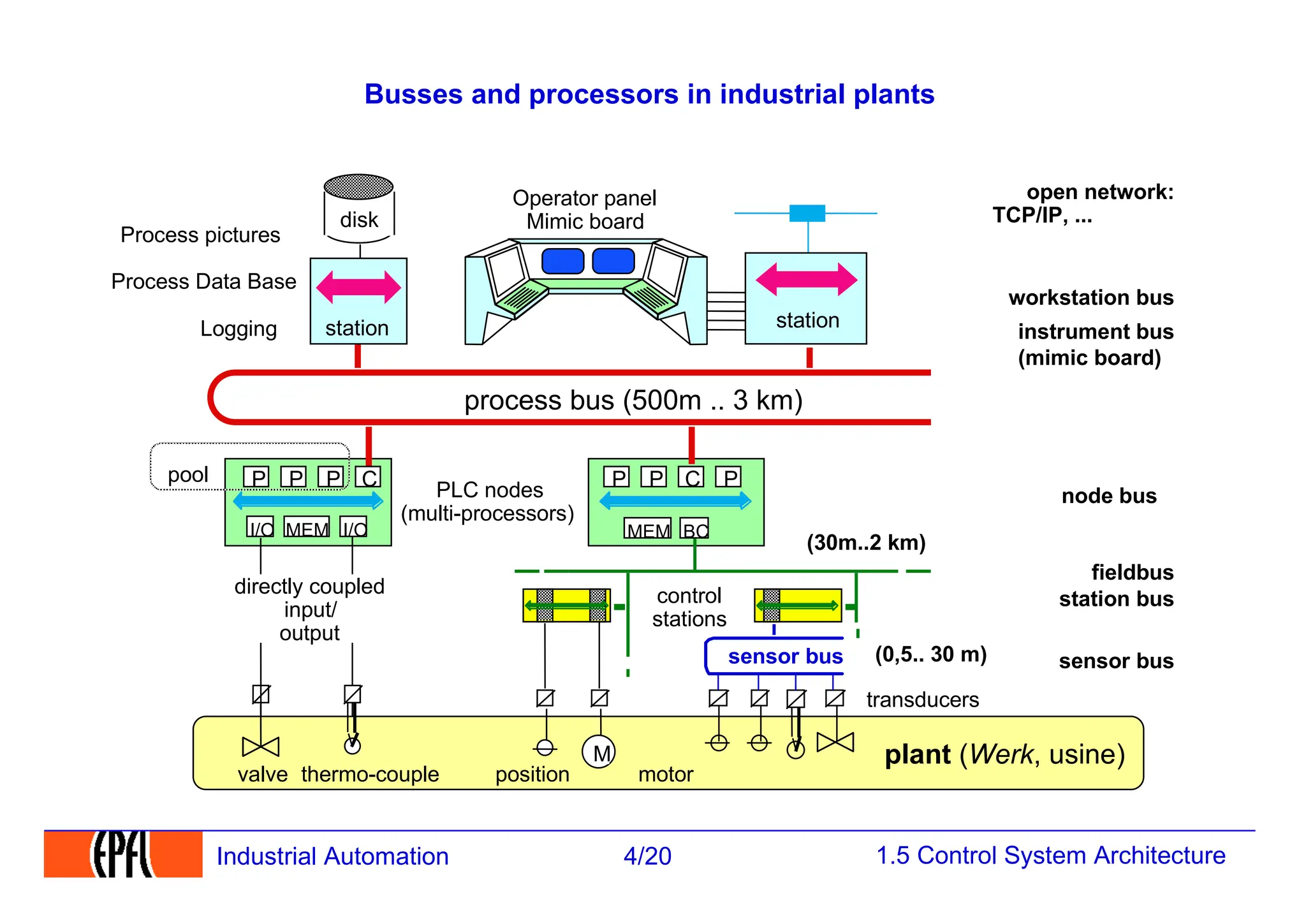

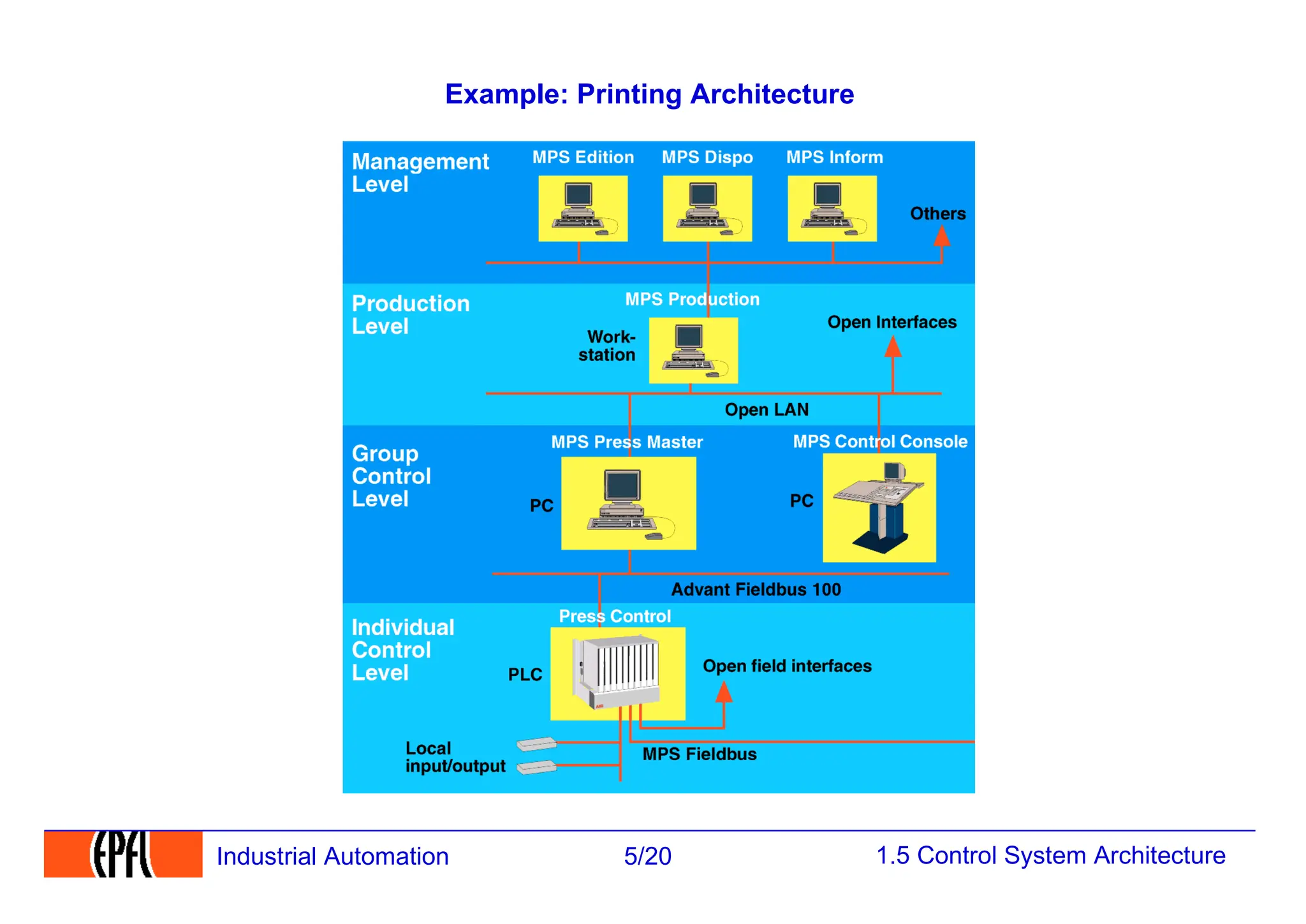

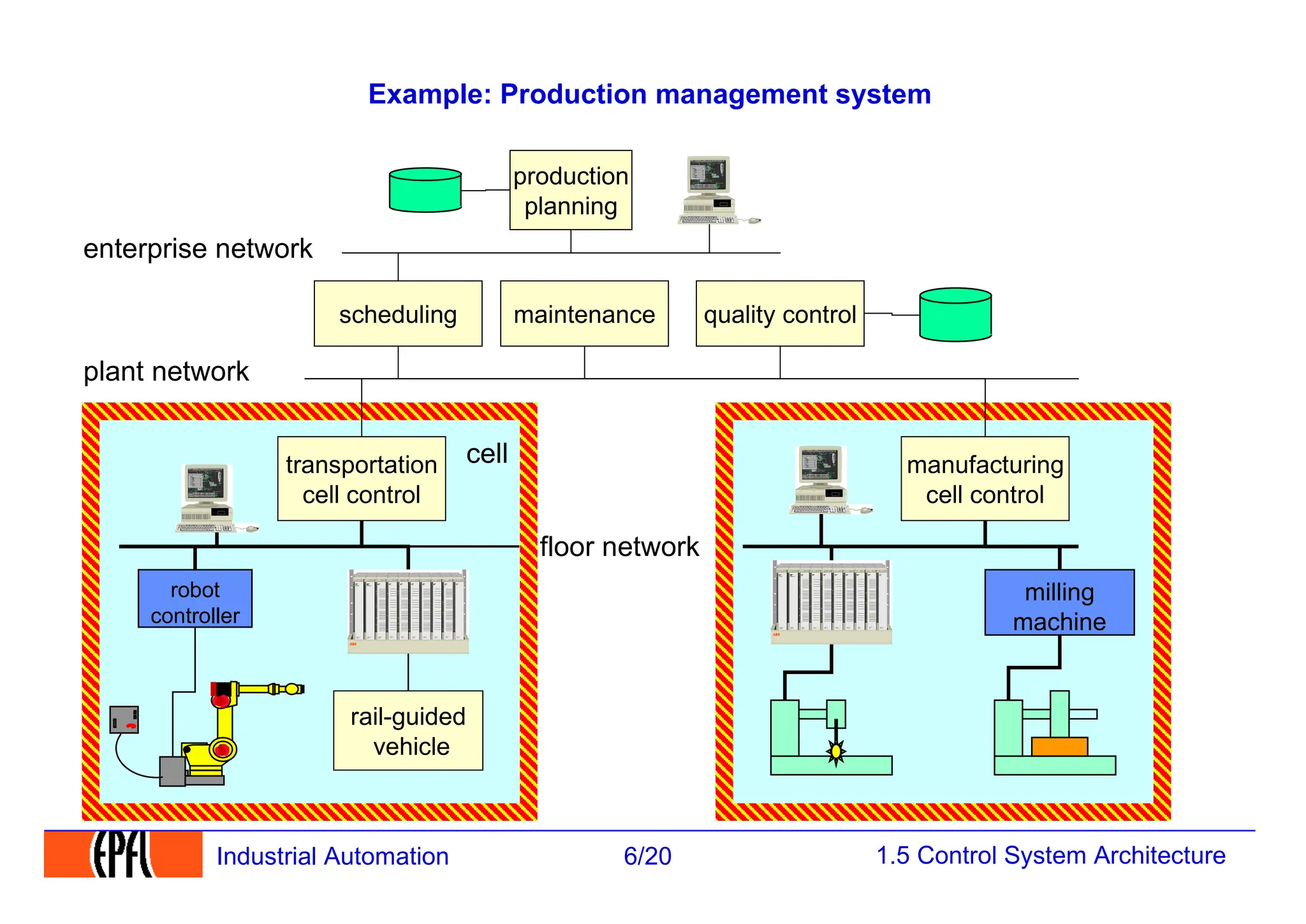

Automation is used widely across many industries and applications. Some examples provided include cars which increasingly use automation for safety features like ABS and steering/braking control. Rail vehicles have over 20 interconnected computers controlling braking, traction, diagnostics and more. Airplanes rely heavily on automated flight control, management and recording systems. Launch vehicles have numerous interconnected computers controlling critical functions. Robots are used for tasks like assembly but have limited range. Flexible manufacturing utilizes automation across conveyors, robots, machines and logistics. Oil, gas and petrochemical plants automate offshore drilling and refining processes in hazardous environments. Printing machines precisely control ink, paper and production using automation.