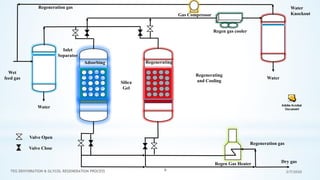

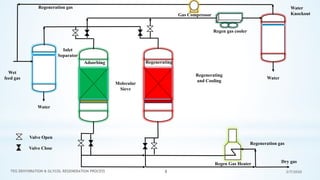

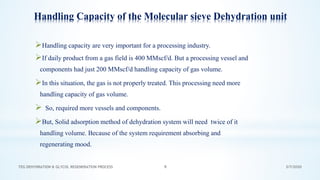

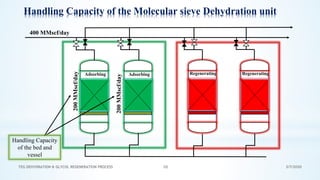

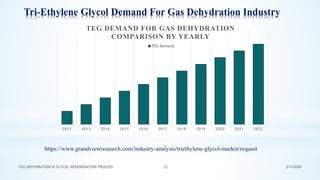

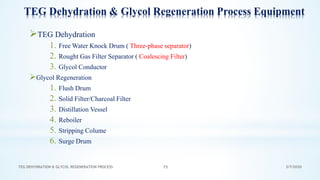

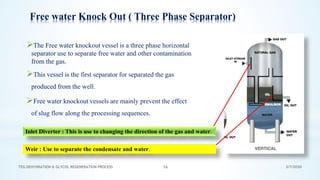

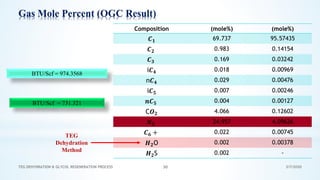

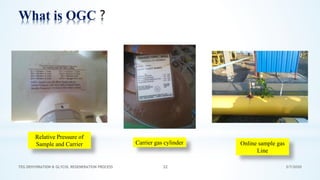

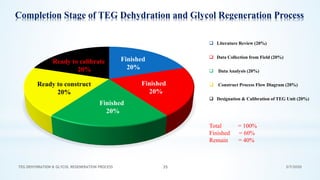

This document presents a comprehensive overview of the tri-ethylene glycol (TEG) dehydration and glycol regeneration process in natural gas treatment. It outlines the methodology, equipment, and capacity requirements critical for effective gas dehydration, while also emphasizing the importance of solid adsorption methods. Additionally, it provides insights into gas composition analysis and the demand for TEG in the gas industry.