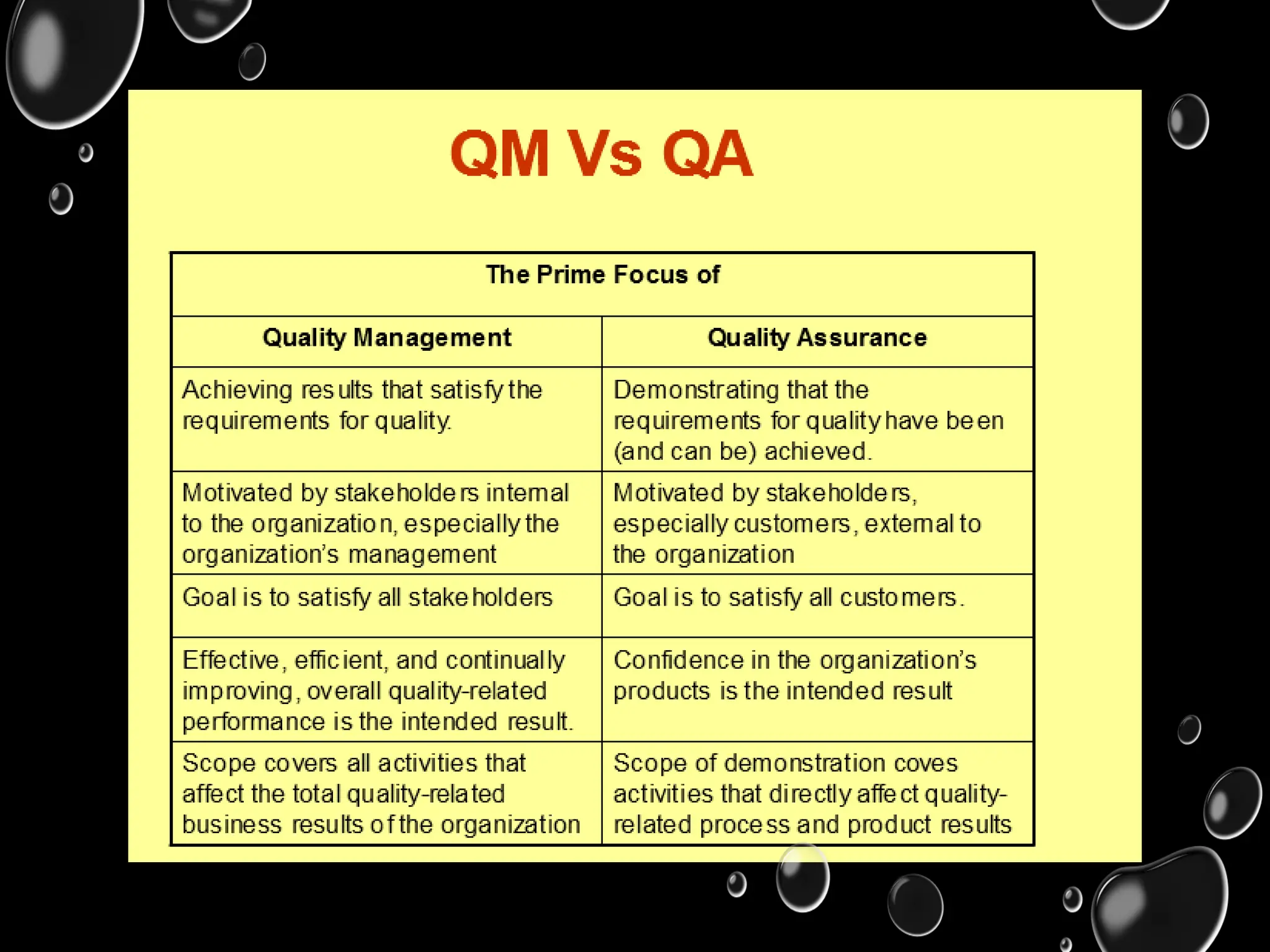

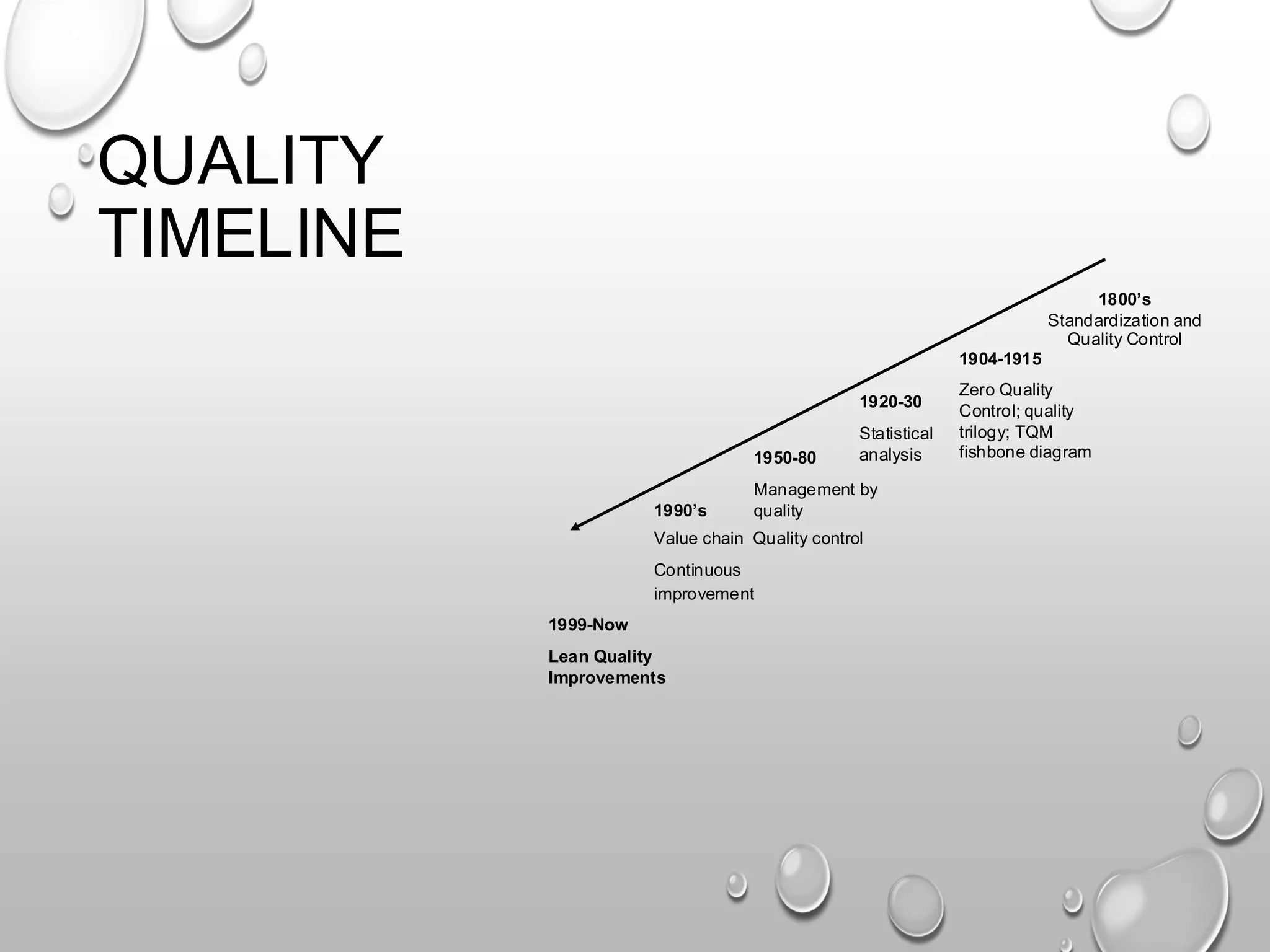

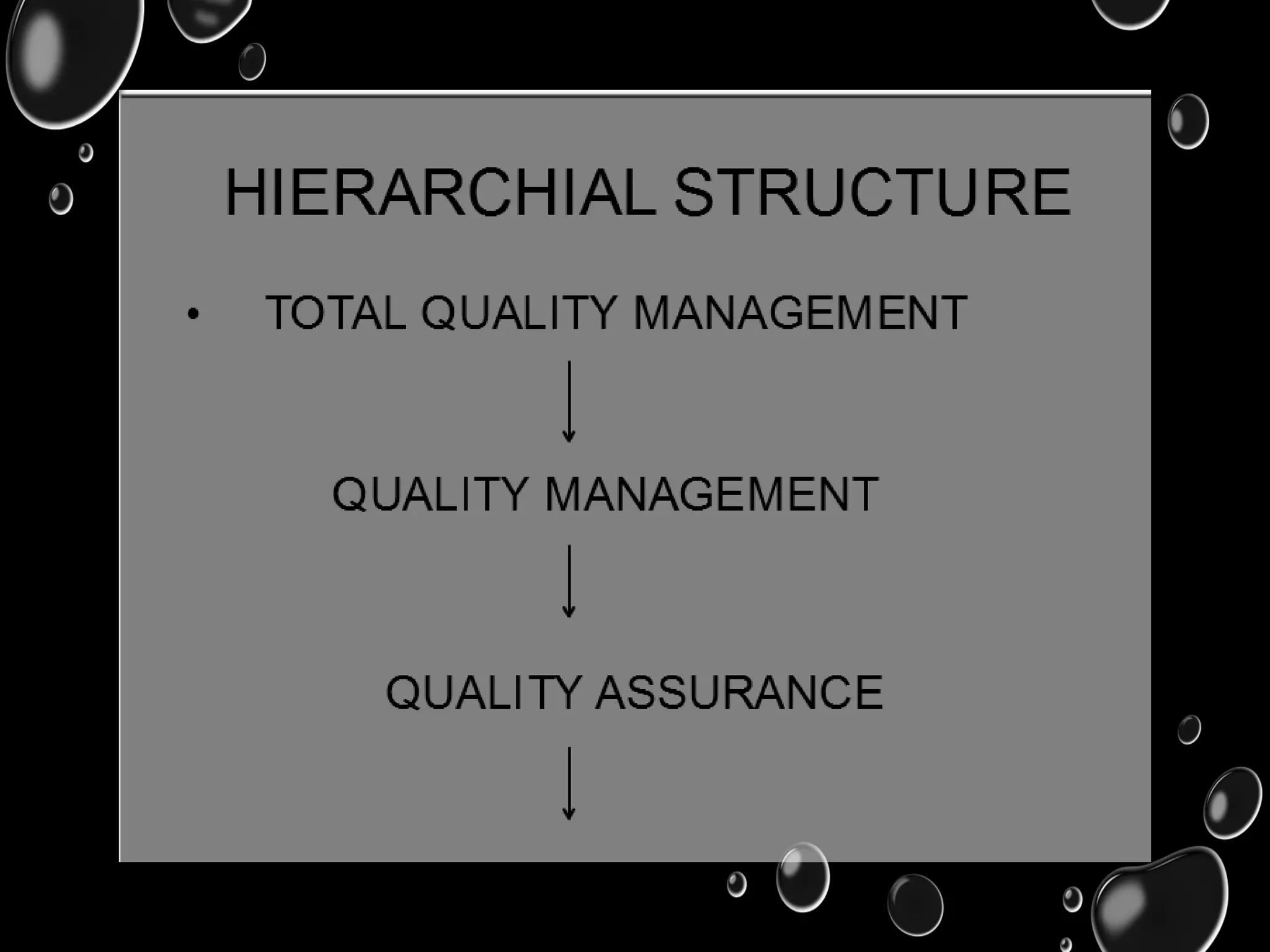

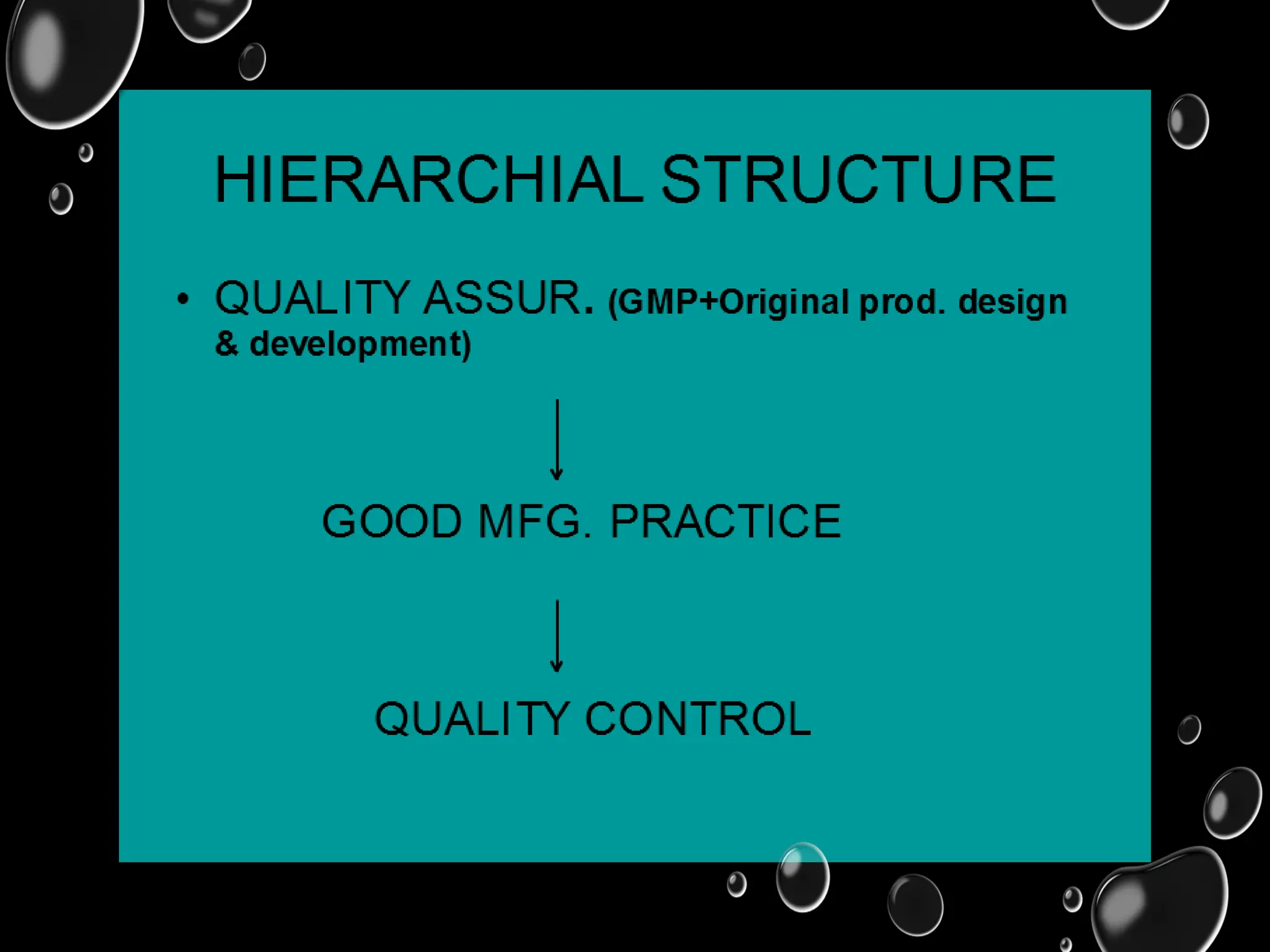

The document outlines fundamental concepts of quality, including definitions, dimensions, and importance, emphasizing the roles of quality control, assurance, management, and total quality management. It highlights the benefits of maintaining high-quality standards, such as reduced costs, improved market share, and enhanced competitiveness. Additionally, it provides a timeline of quality evolution alongside ISO standards relevant to quality management.