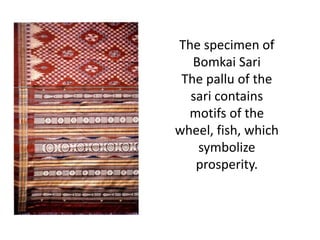

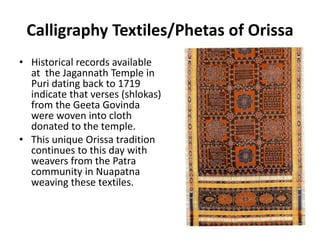

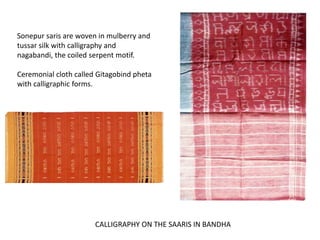

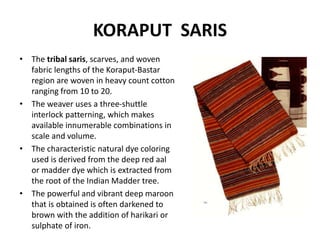

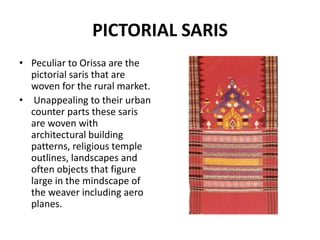

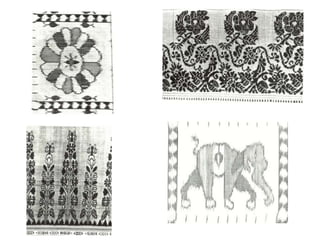

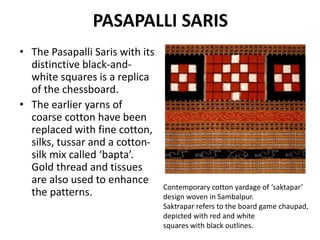

Bandha is a unique type of Ikat textile originating from Odisha, India. It involves intricate tying and dyeing of warp and weft threads before weaving to create elaborate patterns. Key features include curvilinear motifs created through supplementary warp and weft weaves. The craft is practiced by several communities across Odisha, with Sambalpur known for double Ikat and Sonepur known for gold-embroidered textiles. Some distinctive varieties include Bomkai saris featuring joined pallu threads, Gitagobind pheta calligraphy textiles, and pictorial saris depicting local architecture and landscapes.