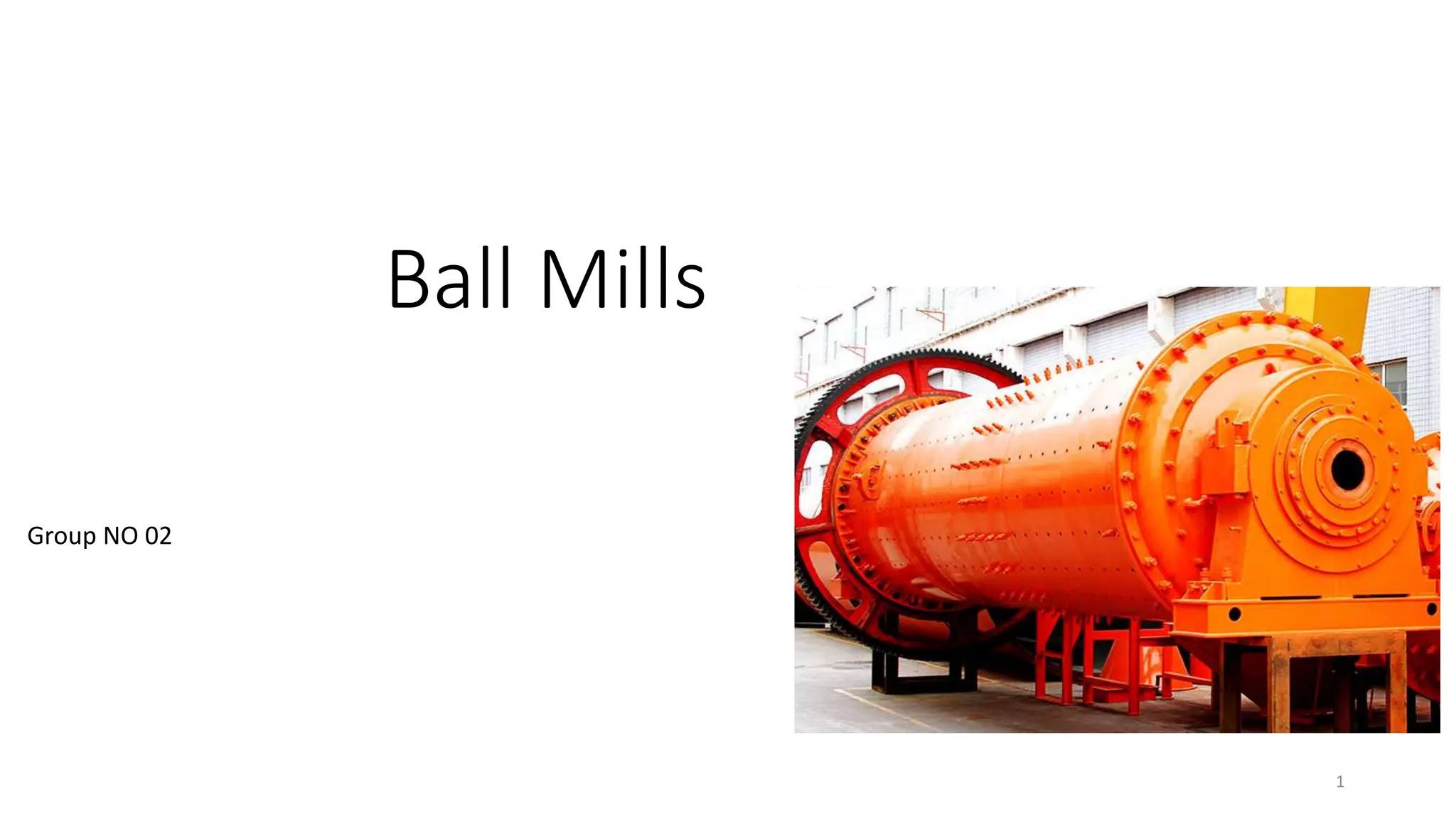

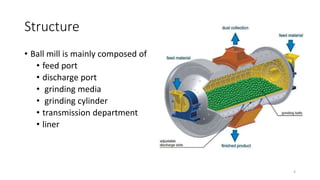

Ball mills are mostly used grinding equipment that can grind materials either wet or dry with high efficiency. They are composed of a hollow cylindrical shell that rotates about its axis and is partially filled with balls made of steel, stainless steel, or rubber materials. The grinding is carried out through impact and attrition of the balls as the cylinder rotates, and the material is fed through the hollow shaft. Ball mills have advantages such as low installation cost, low production cost, and suitability for both batch and continuous operations. However, they also have disadvantages like high noise levels, relatively long milling times, and difficulty in cleaning. Ball mills find applications in grinding materials for industries like coal, pigments, and ceramics.