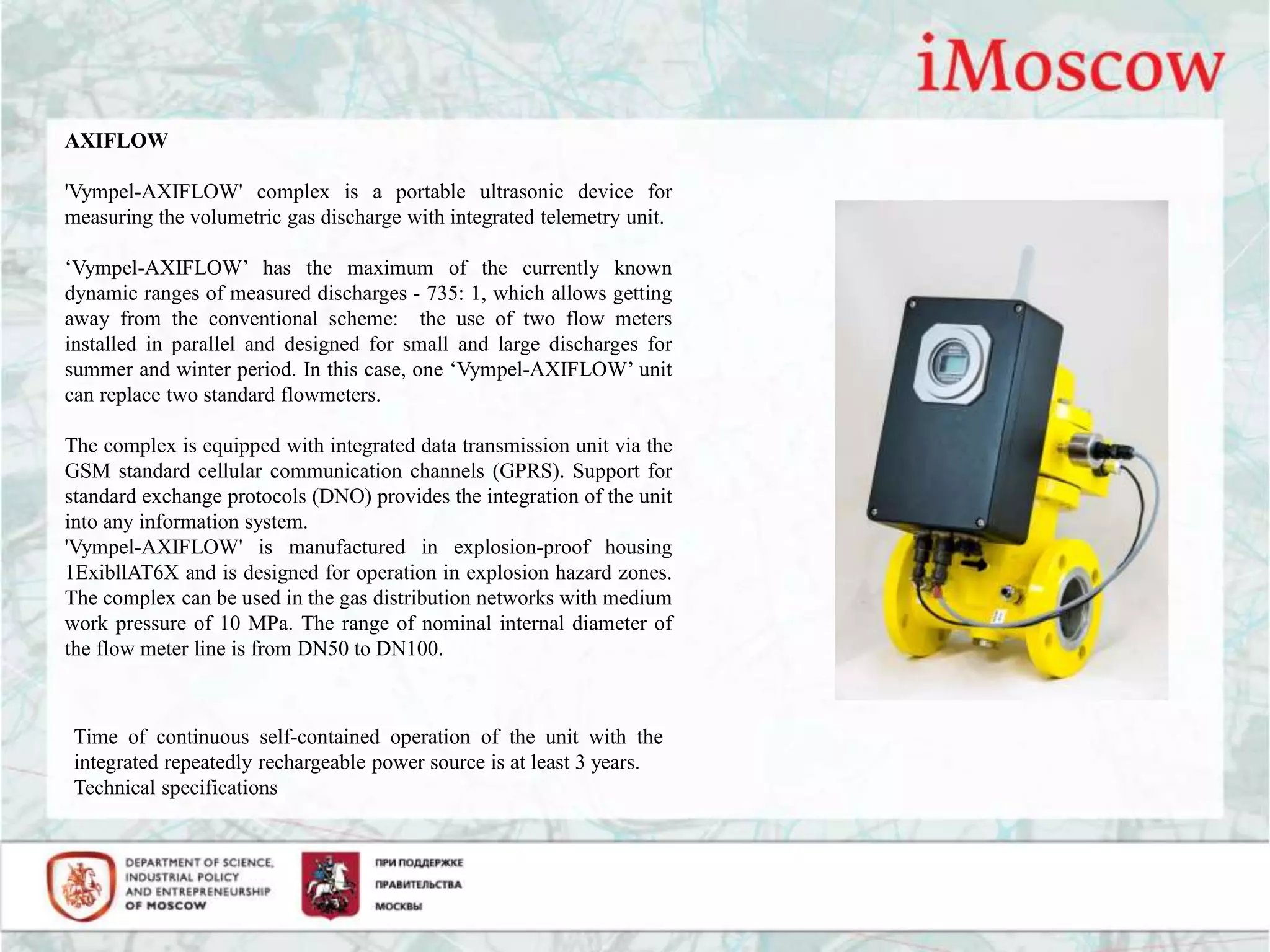

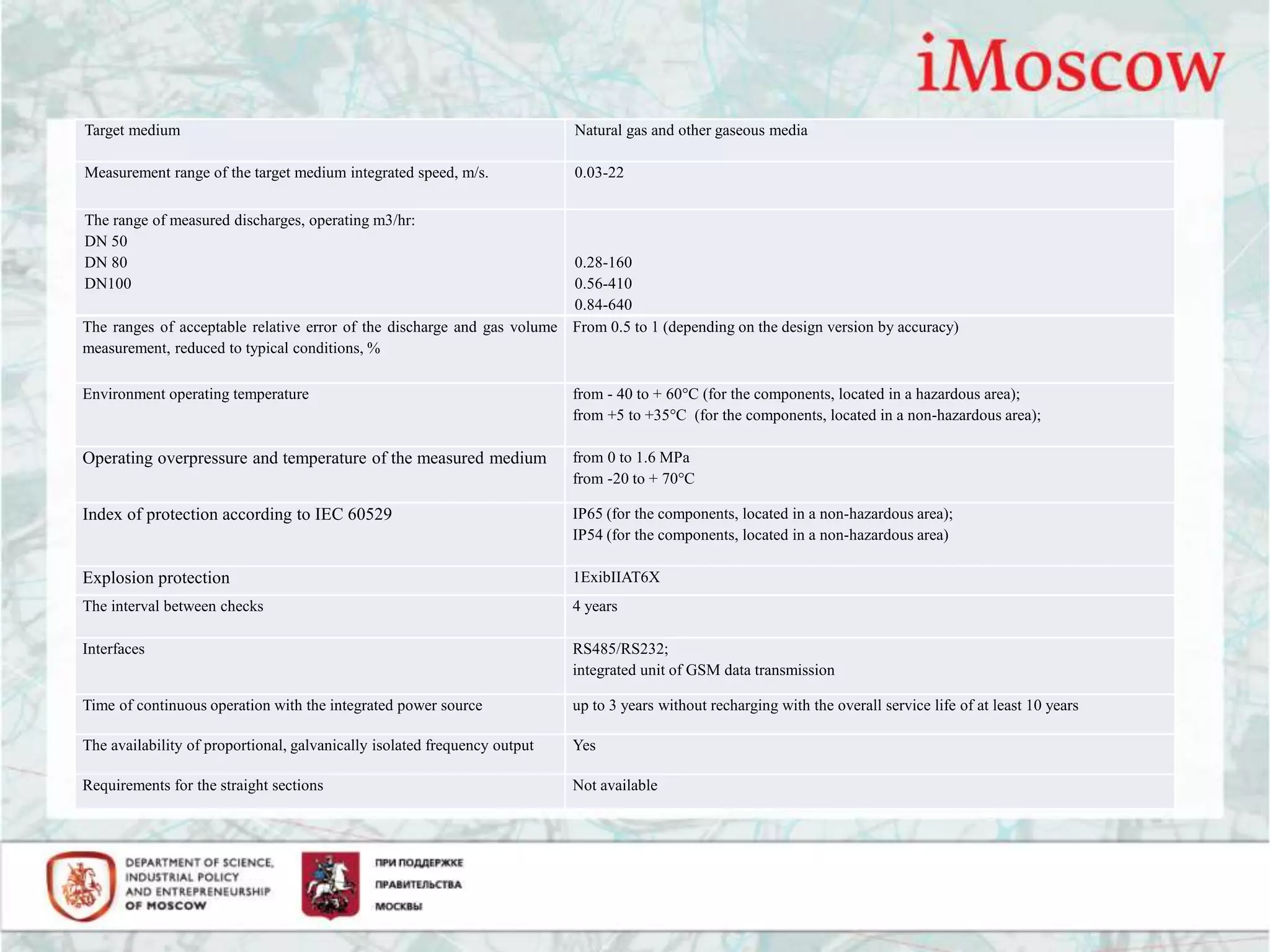

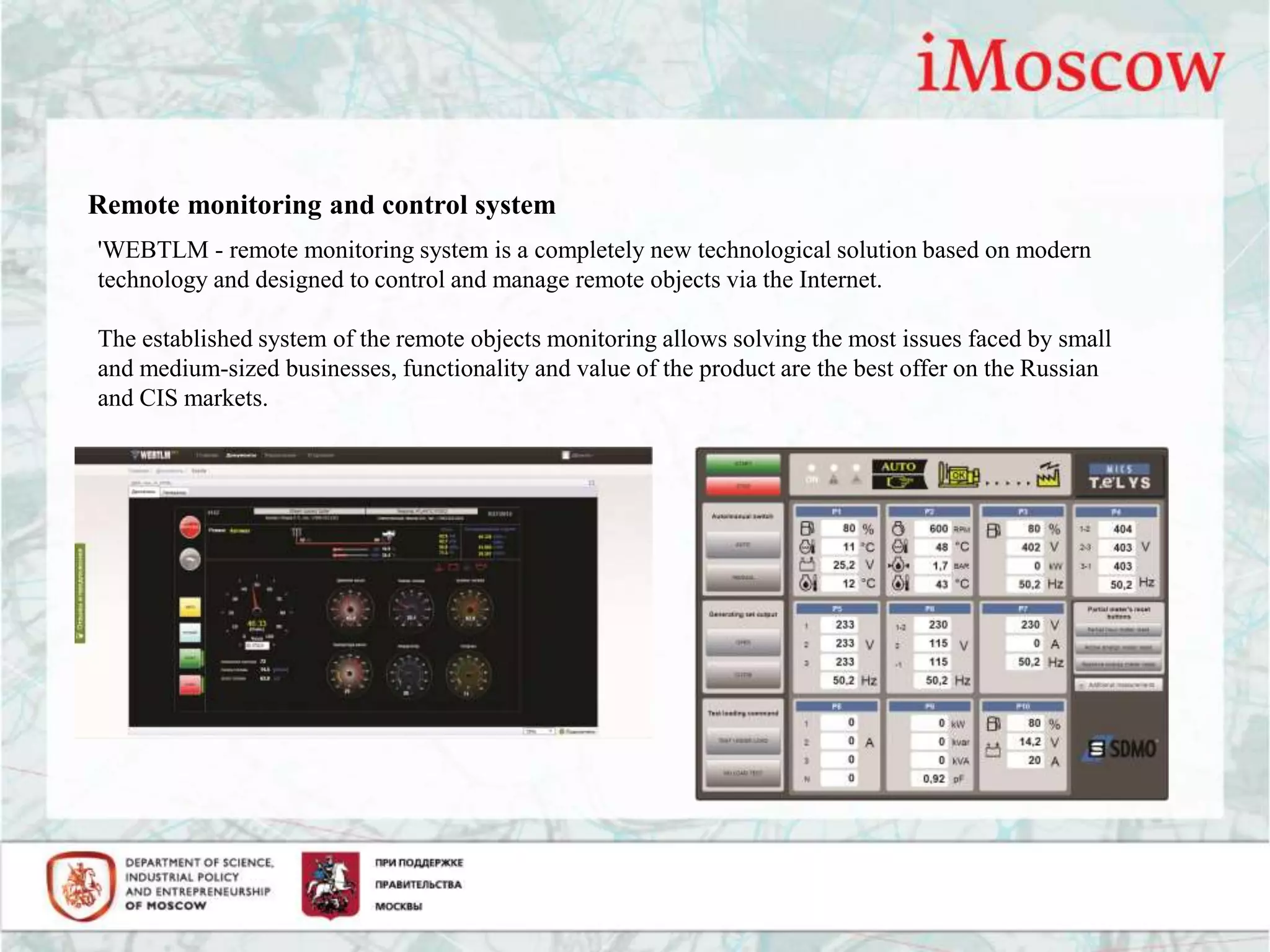

Self-contained telemetry complexes called AKTEL are designed for remote monitoring and control of industrial sites as part of distributed control systems. They are used in industries like gas, oil, energy, utilities, and more. The Vympel-AXIFLOW complex measures gas flow with an integrated telemetry unit and wide dynamic range, replacing two standard flowmeters. The ASDUK-PKS system remotely controls gas shut-off valves up to 1400mm using satellite and GSM communication. The WEBTLM monitoring system uses the internet and mobile apps to remotely monitor industrial objects anywhere.