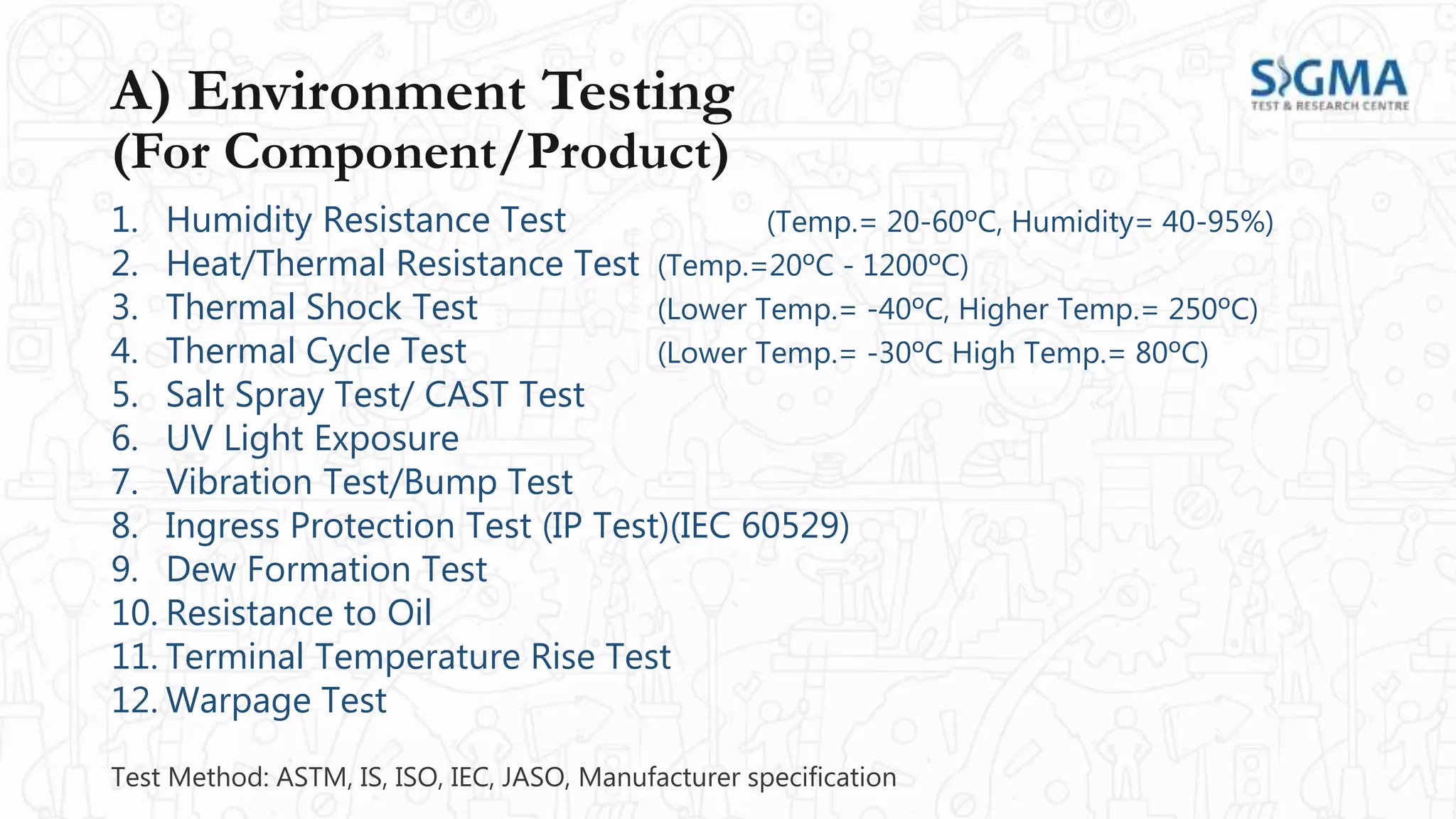

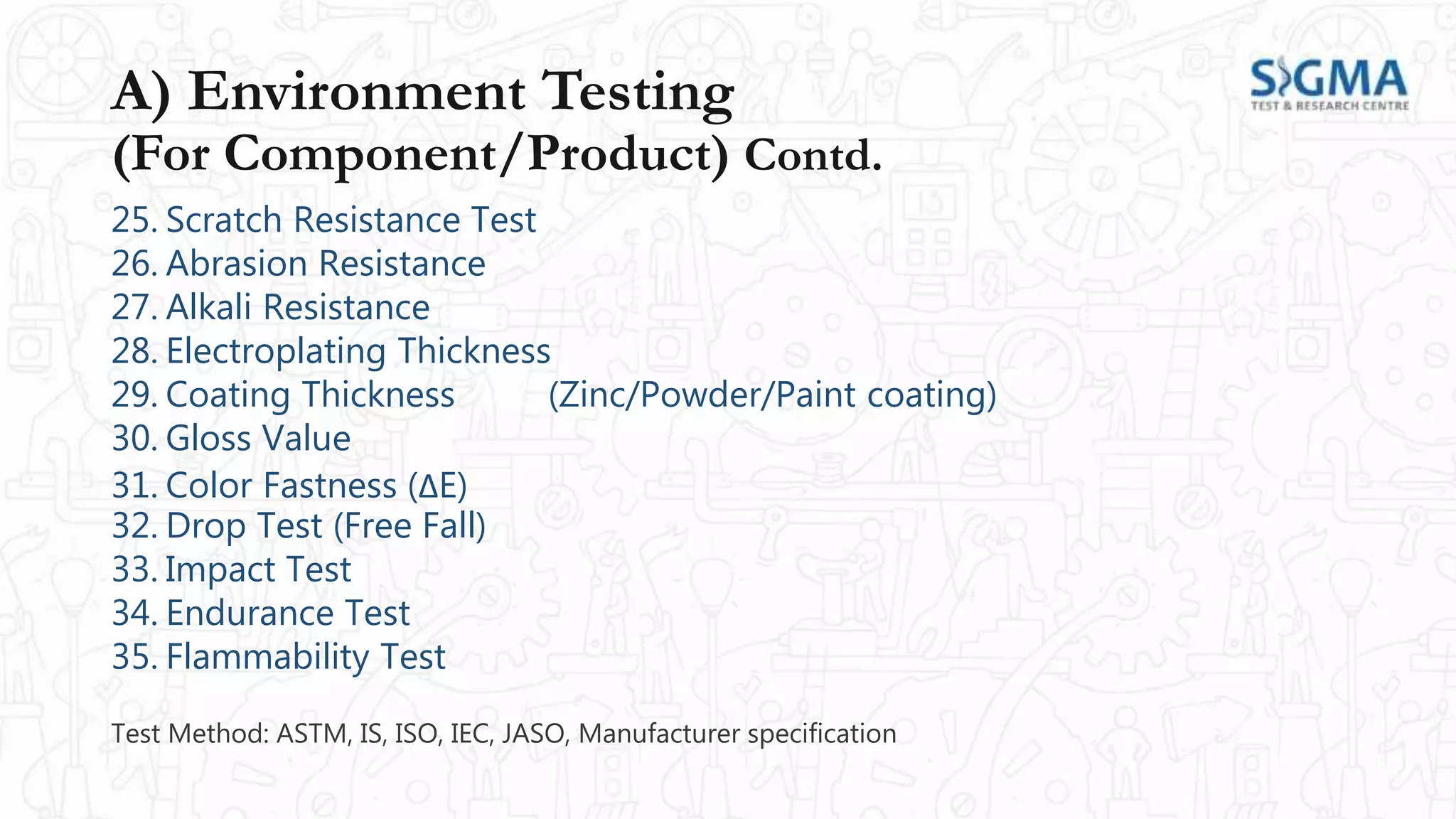

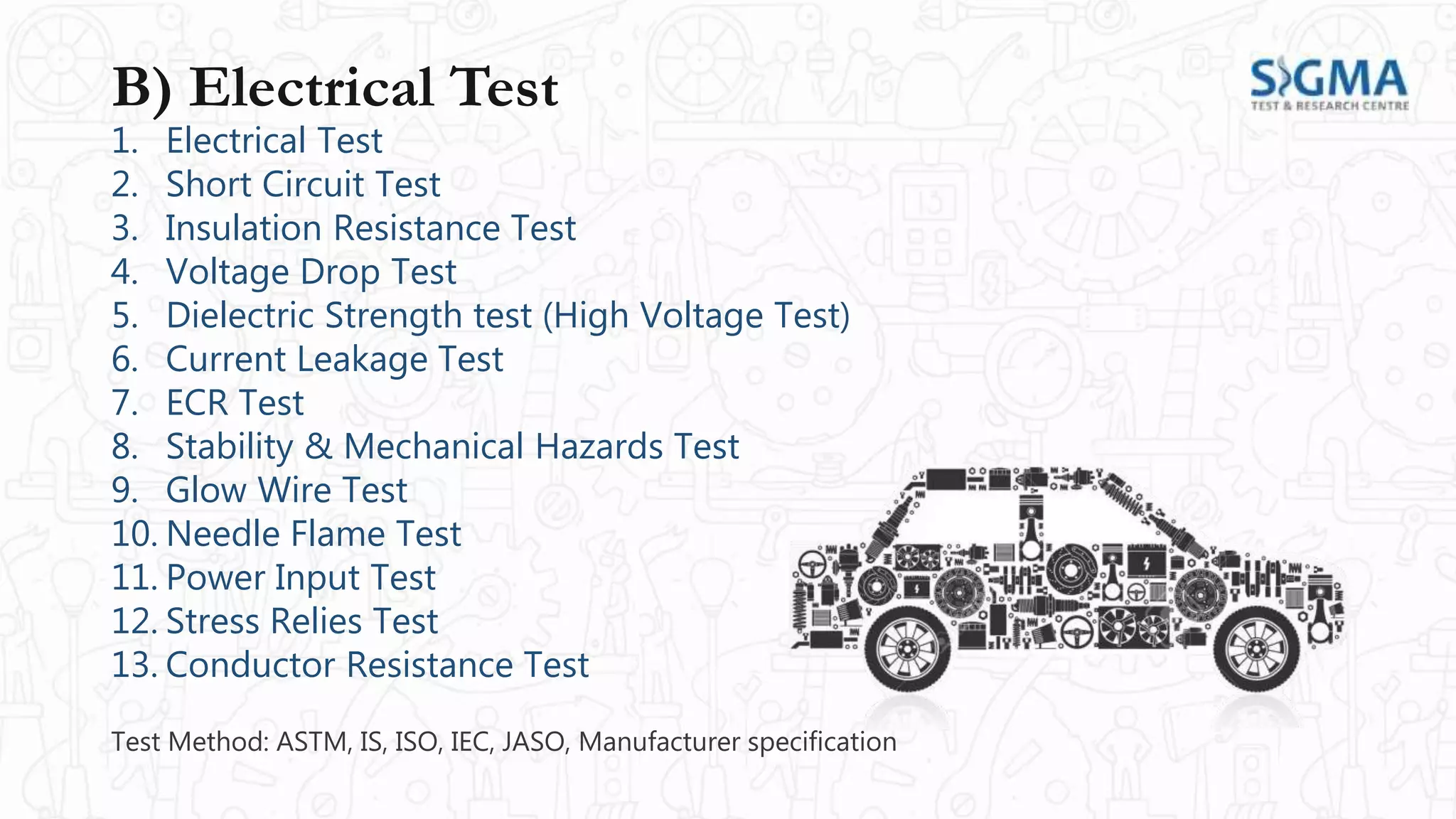

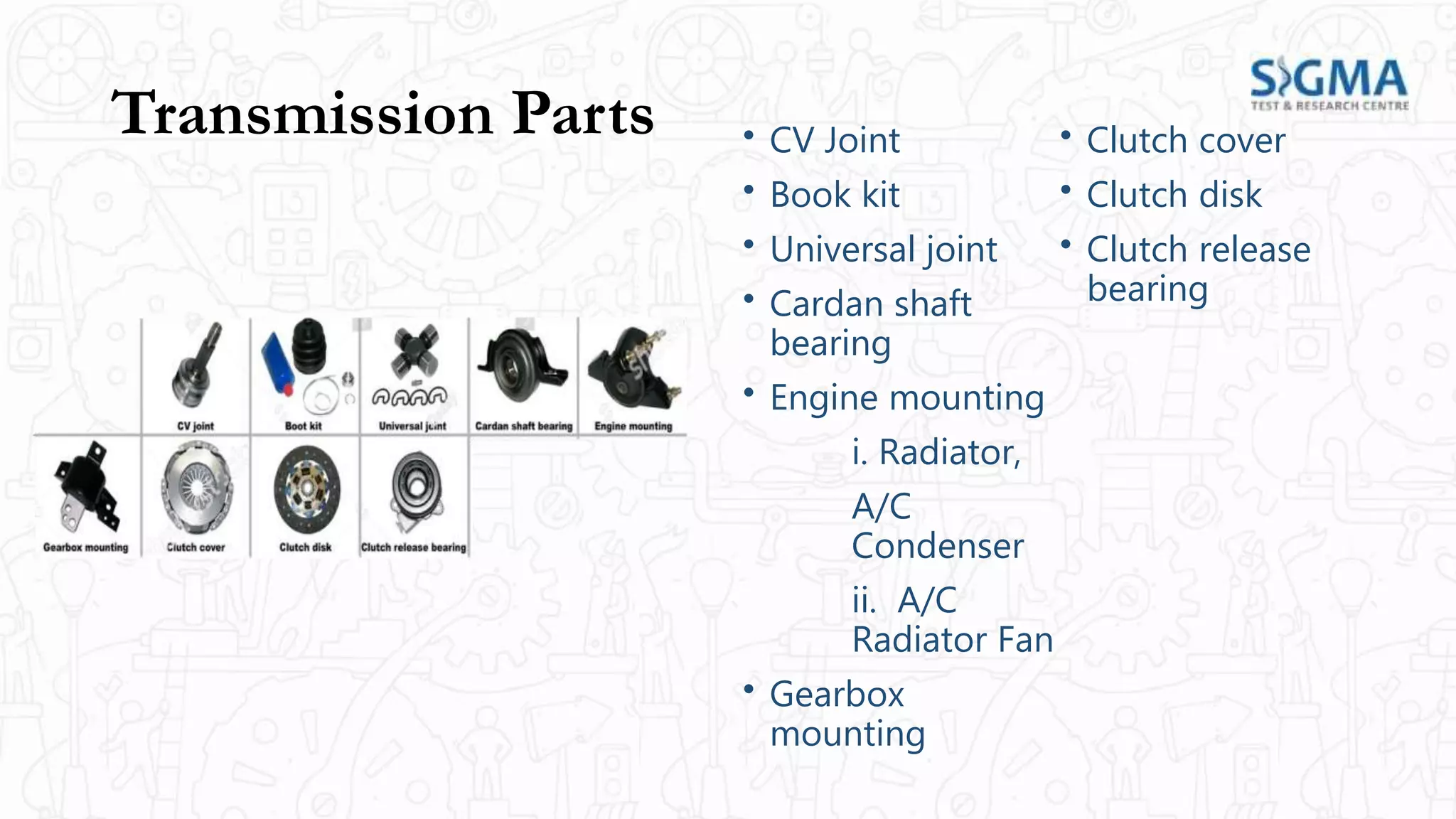

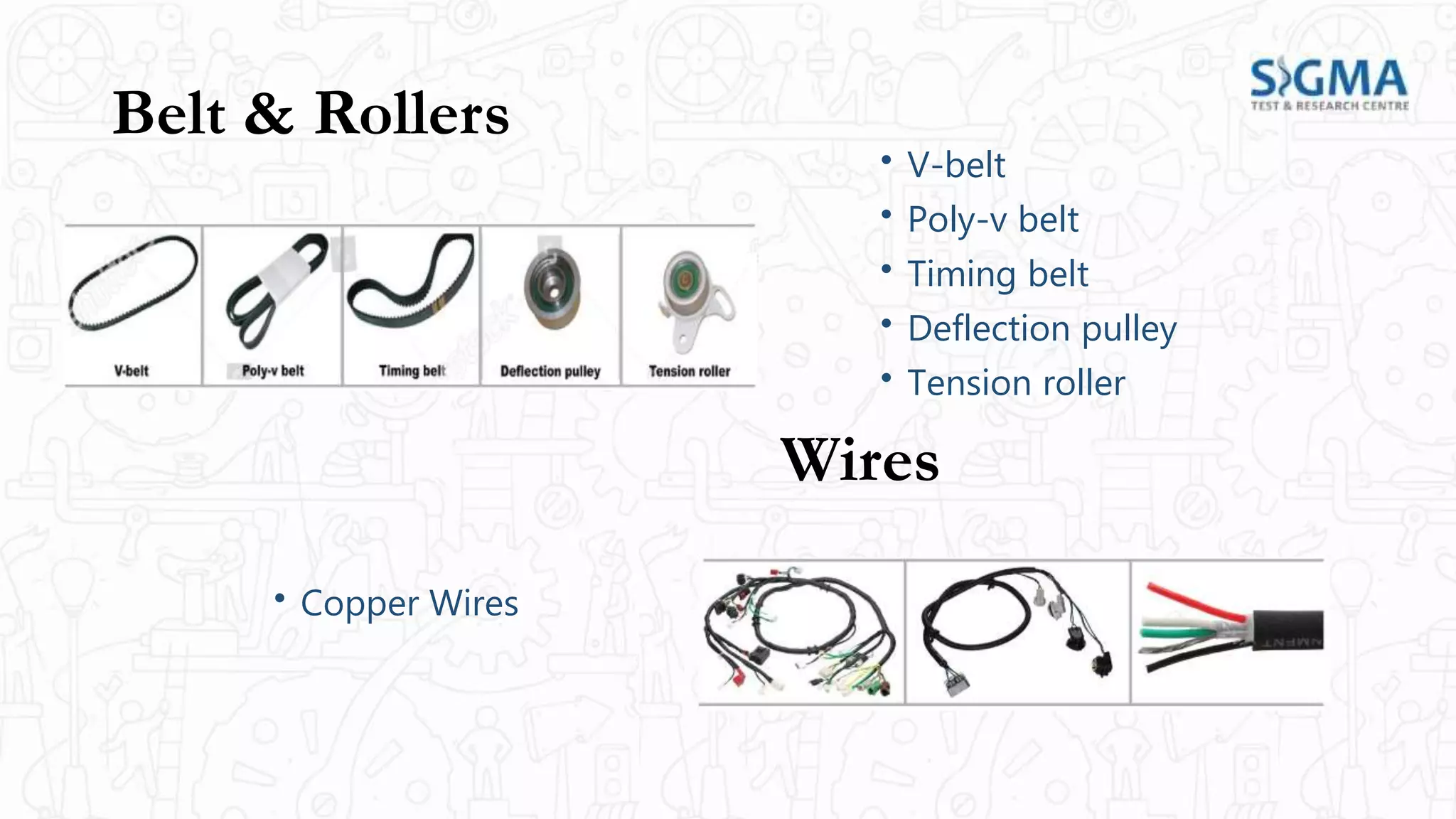

The document outlines a comprehensive testing facility for automotive parts, detailing various environmental, electrical, and material quality tests applicable to components such as steering, transmission, and brake parts. It specifies numerous testing methods, including humidity resistance, electrical insulation, and material identification for rubber and metal components, following standard specifications like ASTM and ISO. Additionally, it includes specific automotive parts listed for testing, indicating a focus on quality assurance in vehicle components.