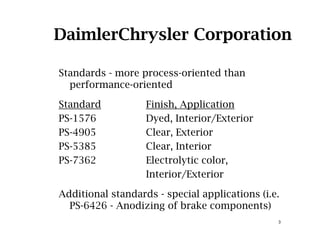

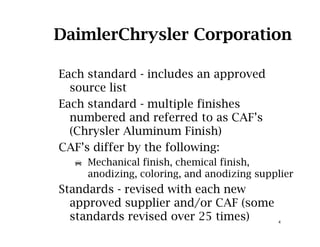

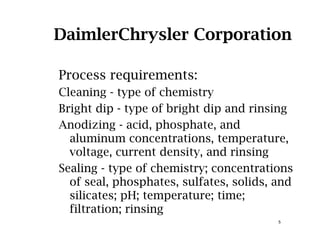

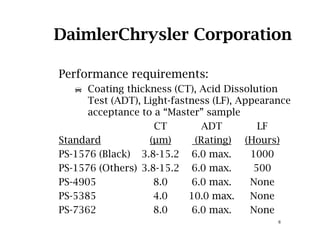

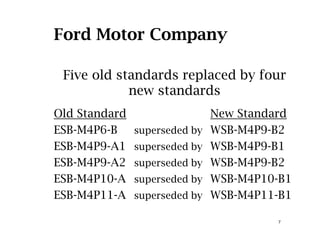

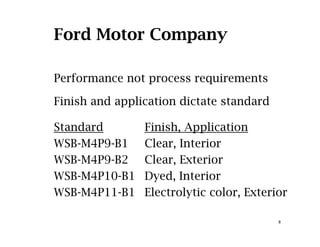

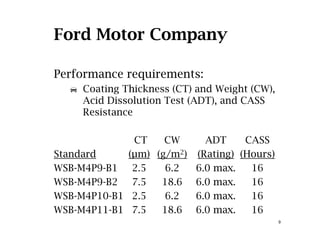

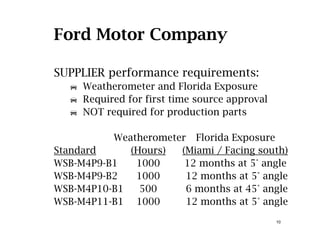

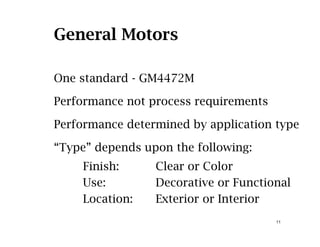

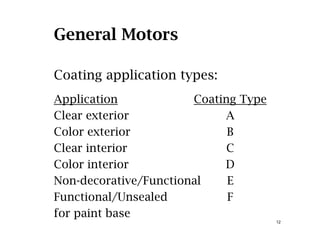

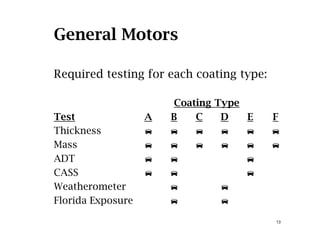

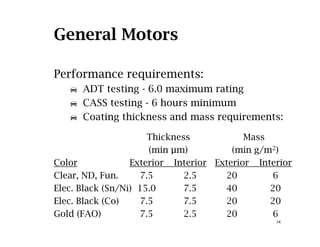

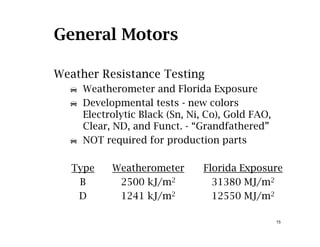

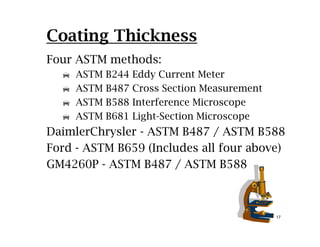

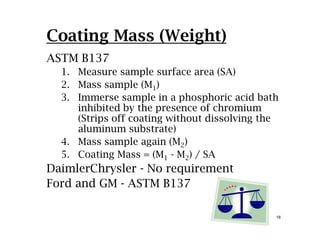

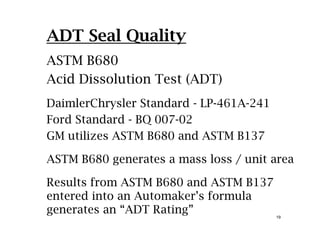

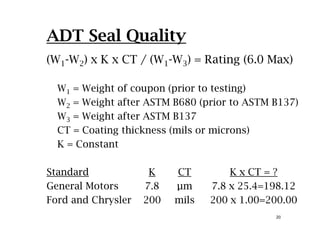

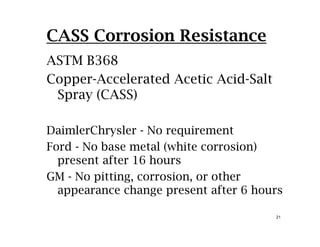

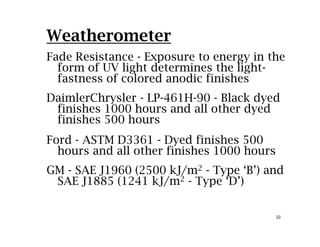

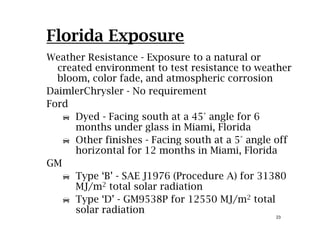

The document discusses anodizing standards and quality control tests for America's major automakers - DaimlerChrysler, Ford, and GM. It provides details on each company's anodizing standards including required finish types, coating thickness and other performance requirements. It also describes quality control tests conducted on anodized parts including coating thickness measurement, acid dissolution testing, corrosion resistance testing, and weathering tests.