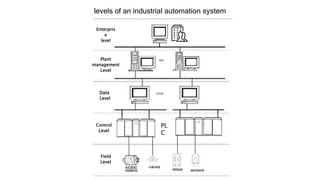

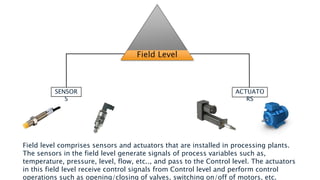

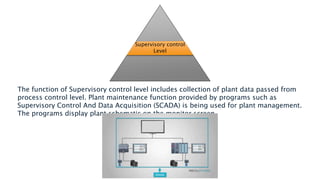

The document outlines the hierarchy of industrial automation systems, explaining the flow of information from field devices to enterprise levels for optimal business management. It describes various levels such as field level, control level, supervisory control level, planning level, and enterprise level, emphasizing the role of sensors, PLCs, MES, and SCADA in data collection and decision-making. Ultimately, the communication pyramid illustrates how better inter-level communication enhances the efficiency of manufacturing systems.