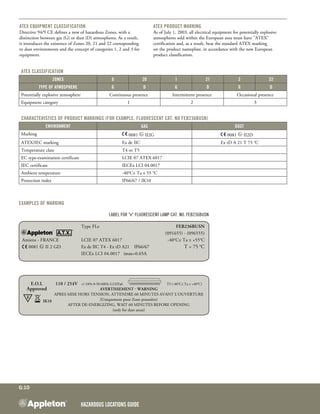

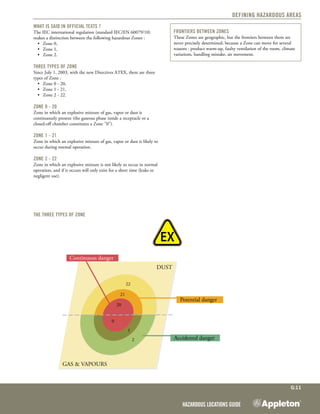

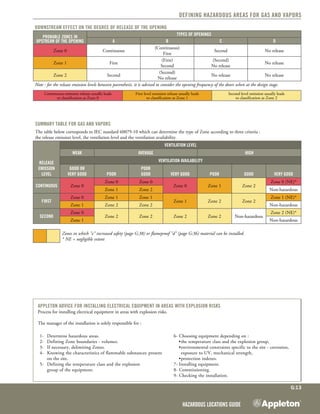

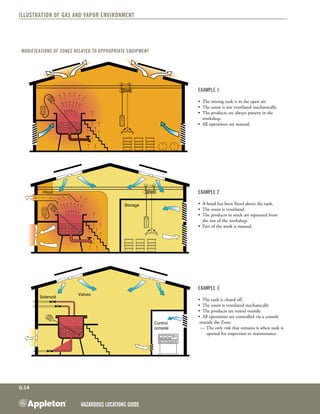

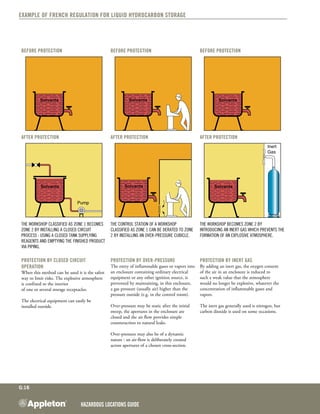

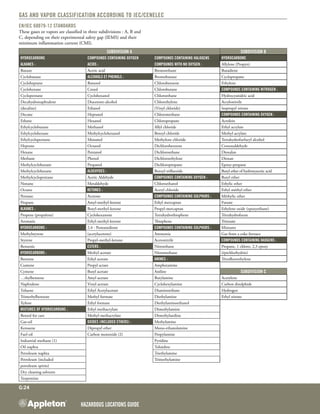

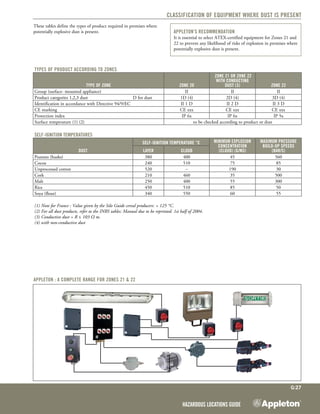

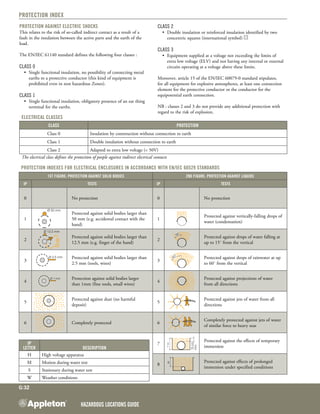

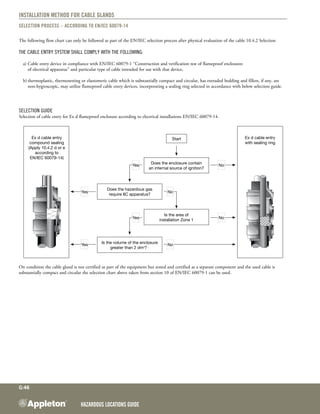

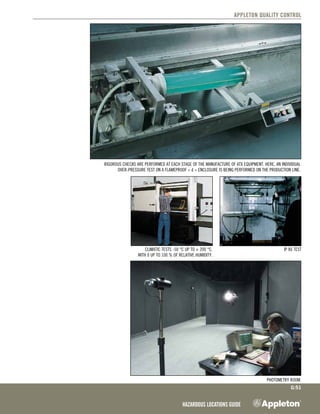

The document provides guidance on installing electrical equipment in hazardous locations with explosion risks. It defines hazardous atmospheres as areas where flammable gases, vapors, mists or dusts are present in concentrations within their explosive limits and an ignition source is possible. The guide outlines the necessary conditions for an explosion to occur, defines explosive and potentially explosive atmospheres, and lists common substances that can produce explosions. It also compares gas and vapor classification standards between IEC, CENELEC and NEC and provides selection guidance for equipment in different hazardous environments.