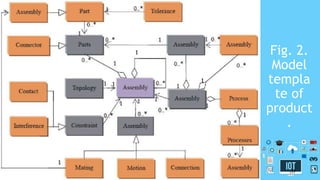

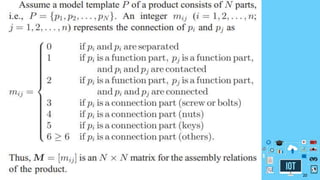

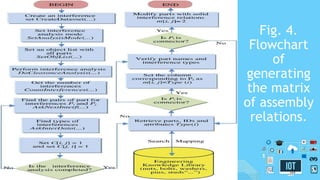

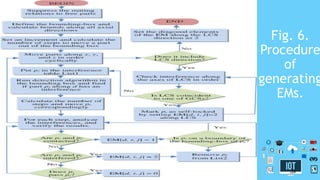

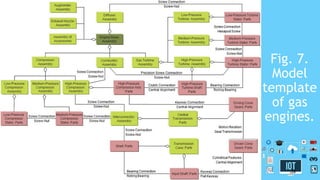

IoT and cloud computing can help automate assembly modeling systems to deal with complex products and changes. The paper proposes using an object-oriented product template to define assembly relations and algorithms to retrieve relational matrices. Assembly modeling of aircraft engines is used as a case study. The key innovations include a modular architecture, integrated templates, and automated algorithms to retrieve assembly matrices from CAD models for planning.