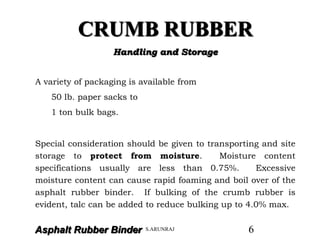

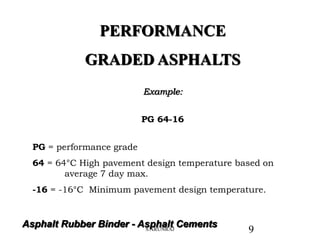

The document provides a comprehensive overview of asphalt rubber binder, including its components, properties, and quality control measures. It details the blend of asphalt cement, crumb rubber from reclaimed tires, and various additives necessary for producing the binder, along with specifications for different climate conditions. Additionally, it addresses the importance of testing and monitoring during production to ensure desired material properties are maintained.